Reducing the Cost and Complexity of Dimensional-Weight Shipping Charges

The carrier practice of applying dimensional-weight shipping charges is here to stay and will likely be adopted for additional modes of transport in the future.

The process of shipping and managing your freight expenses is becoming more dependent on the size of your freight and the space it occupies than ever before.

Many carriers are, in essence, selling space on their vehicles.

All air freight and most ground freight on major carriers now require declared dimensions for correct manifesting.

Without a declaration you are subject to carrier audits and accessorial back-charges.

These back-charges can hurt margins if you apply “Flat Rate” charges to customer shipments, and they can cost you (the vendor/shipper) money if you are billing customers for reimbursement of actual freight costs.

Either way, if you are not declaring dimensions you are probably headed for disputes with your carrier over carrier-imposed dimensional-weight charges that will be costly and difficult to resolve.

Rules

To realize how costly it can be, you must first understand the rules a carrier uses to charge for handling your shipments. FedEx and UPS use similar formulas to determine rates for domestic and international shipments and surcharges. While domestic rates vary for ground versus air transport, all expedited shipments—including next-day air and two-day air—are subject to dimensional weighing, regardless of the size of a parcel. Ground shipments, however, are only subject to dimensional weighing if the parcel is greater than 5,184 cubic inches in volume (three cubic feet). For both domestic air and ground shipments the dimensional-weight formula is the same: (Length * Width * Height)/194. For international shipments all freight is subject to dimensional weighing regardless of the size, but the formula uses a lower ‘dim factor’ of 166: (Length * Width * Height)/166.

In addition to dimensional-weight charges, there are other size-related UPS and FedEx surcharges that have been announced by both carriers. An Additional Handling Fee is charged when the parcel is greater than 60 inches in length or a package measures greater than 30 inches along its second longest side. As well, both carriers charge a fee for oversize packages. FedEx refers to this as an oversize fee, UPS calls it a large package fee, but both carriers use the same formula: If the length plus the girth (girth is twice the width plus twice the height) is greater than 130 inches, you pay a $45 fee. All of these fees are in addition to the base rate, irrespective of the calculated dimensional-weight or actual weight of the shipment. The United States Postal Service has also increased oversize rates for parcel post.

Accurate Measurements Matter

When cubing a warehouse or dimensioning a shipment, companies increasingly use the information about size and weight of parcels for inbound and outbound operations.

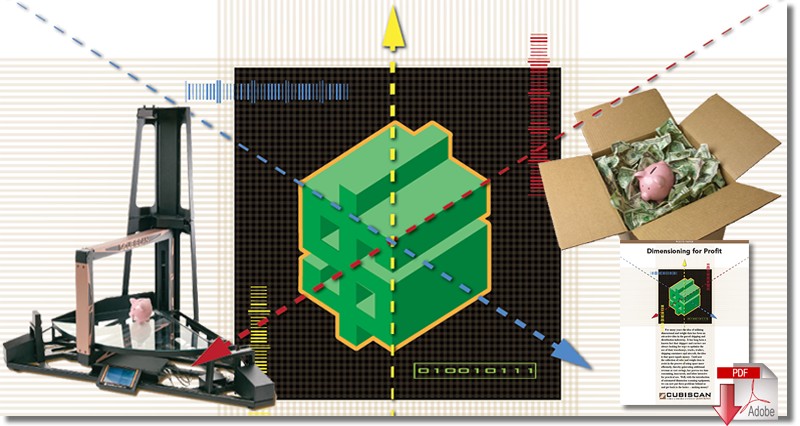

Investments in automated cubing equipment that captures the dimensions (length x width x height) of both inbound and outbound shipments are on the rise—but for different reasons, according to Randy Neilson, director of sales and marketing for CubiScan.

“At receipt, companies are trying to obtain more accurate size and weight information about each stock keeping unit (SKU) stored in their warehouse,” Neilson explains. “This could be done with a tape measure, but there’s an opportunity for human error in capturing and recording the data.”

The equipment records the cube data and automatically ties it to the product record in a warehouse management system’s (WMS) master data file. Both cube and weight information is analyzed by the WMS to determine the best putaway location, whether in racking or automated storage.

Inbound cubing systems are frequently smaller machines that measure stationary boxes or cases placed on them. Product sizes can range from 0.5 x 0.5 x 0.5 inches to 48 x 39 x 40 inches, says Neilson. Further, when storing eaches, “machines equipped with sensing technology can measure irregular or odd-shaped items,” he adds.

On the outbound side, two different types of automated dimensioning systems are increasingly being installed. Large static systems are being used to measure palletized loads placed upon them by forklift, and they are frequently coupled with scales.

For high-volume, small parcel shippers, in-motion, dynamic dimensioning equipment is installed on conveyors. These in-line systems capture measurements at rates up to 600 feet per minute (combined with in-line scales, lines move at rates from 200 to 300 feet per minute, says Neilson, as weighing takes longer.)

While shippers are accustomed to declaring the weight of a pallet load to a less-than-truckload (LTL) carrier, or of a package to a parcel carrier, new rules are dictating charges based on volume and density. That’s because, for example, a carton or pallet load of AAA batteries has a very different weight and dimensions from a carton or pallet load of stuffed animals, Neilson says.

“Carriers want to equalize load density charges,” he explains, “so, if a shipper sends something without declaring the dimensions, they may get a charge they weren’t expecting.” Additionally, analysis of dimensional data can be used to negotiate better rates with carriers, further justifying the cost of the equipment.

Results

It is clear that providing accurate dimensions to your shipping software is critical. Any good shipping system will handle all of the calculations required by freight carriers, but the software is only as good as the data coming in. If dimensions are left blank, most shipping applications assume dimensional-weight and/or other size-based surcharges are not a factor. Consequently, billing customers for freight charges without considering dimensions can cost you a lot of money. How much depends on how much you ship.

We recently analyzed the shipping expenses of a large company that sells motorized recreational equipment, parts, and accessories. It shipped thousands of parcels a day, many of which were spare parts by next-day air. The company wasn’t declaring any of the dimensions for its small-parts shipments. On average there was a $3 difference for each parcel, adding up to under-billings of $5,000 per month. Needless to say, overlooking dimensional declarations can add up quickly, making it more than just a small and inexpensive oversight!We recently analyzed the shipping expenses of a large company that sells motorized recreational equipment, parts, and accessories. It shipped thousands of parcels a day, many of which were spare parts by next-day air. The company wasn’t declaring any of the dimensions for its small-parts shipments. On average there was a $3 difference for each parcel, adding up to under-billings of $5,000 per month. Needless to say, overlooking dimensional declarations can add up quickly, making it more than just a small and inexpensive oversight!

Solutions

One way you can address the problem and leverage the functionality of your shipping software is to employ automated dimensioning (or cubing) equipment. These devices use various forms of non-contact sensing technology (such as lasers, cameras, ultrasound, infrared light, light diode sensors, etc.) to quickly and accurately assess parcel dimensions. Most dimensioning systems can be combined with scales and barcode scanning technology to form highly efficient cubing, weighing and identification stations.

Several types of systems are available: small static, in-motion, and large-freight systems. Small static systems are the least expensive. They generally replace a small to medium-sized bench scale, are usually designed for hand-held parcels under 70 lbs, range in price from $5,000 to around $20,000, and typically have a throughput capability of 100 to 400 packages per hour.

Conveyorized (or “in-motion”) cubing systems are typically used in high-volume, highly automated facilities along with fixed-mount barcode scanning technology (capable of single to six-sided scanning). These systems come with or without a scale and are generally designed for hand-held parcels under 70 pounds. Some in-motion systems can measure non-singulated and/or some non-cuboidal freight, but require freight to be singulated if in-motion weighing is necessary. Conveyorized dimensioners are quite productive, operating at belt speeds up to 600 feet per minute (generally slower with a scale) and processing anywhere from 2,000 to over 20,000 pieces per hour (lower if a scale is involved). Pricing ranges from the low teens to over $40,000 for a “premium” integrated system that measures and weighs.

Large-freight cubing systems (typically called pallet-dimensioning systems) are usually combined with a floor scale or forklift scales. These systems are generally used to measure full pallet loads, but you can also utilize them for single and multi-piece shipments. Most are designed to work with “non-cuboidal” freight (since most pallet loads are anything but perfect). Nearly all pallet dimensioning systems use multiple sensors to reduce or completely eliminate “shadowing” (i.e., the inability to conclusively see a load’s length and width dimensions from above). Additionally, they are usually designed to allow pallet dimensions and weight to be “tared off.” Throughput rates range from 50 to over 120 shipments per hour. Most systems are static in nature, but conveyorized pallet dimensioners are also available.

There are several things you should look for in an automated dimensioning system. First, if you’re charging your customer based on the output of your scale and/or dimensioner you may have a legal-for-trade (LFT) application. This may require a Weights & Measures type-approved device. Your vendor should be able to explain LFT regulatory issues (beware if they can’t). Type-approved LFT devices have been independently proven accurate and consistent to certain regulatory performance standards. An approved system may have other desirable qualitative and reliability attributes. Second, you’ll want a system that can interface directly and easily with your shipping software. Data/user interfaces can be customized to work directly with many computerized shipping systems. This is a critical feature, since a good dimensioner without a functional interface is not very useful. Last, a system that is consistent in operation, durable, easy to service, and has a good user/data interface is best.

The carrier practice of applying dimensional-weight shipping charges is here to stay and will likely be adopted for additional modes of transport in the future. Knowing industry and carrier-specific policies as well as using proven shipping software and automation technology will help you save time and effort, reduce costs, and eliminate unpleasant surprises.