Precise Fine Positioning for Single and Double-Deep Racking

SICK’s new Rack Fine Positioning app and InspectorP 2D vision sensor provides a more efficient method to accomplish fine positioning tasks.

With automated storage and retrieval systems (ASRS) being used in most manufacturing and distribution facilities, many companies are looking for a more efficient way to accomplish precise fine positioning.

In recent years, vision solutions have become the common solution to help complete these tasks, but many were not as precise as they could be.

Now there’s a solution available to save rack space to maximize storage capacity with high-precision positioning.

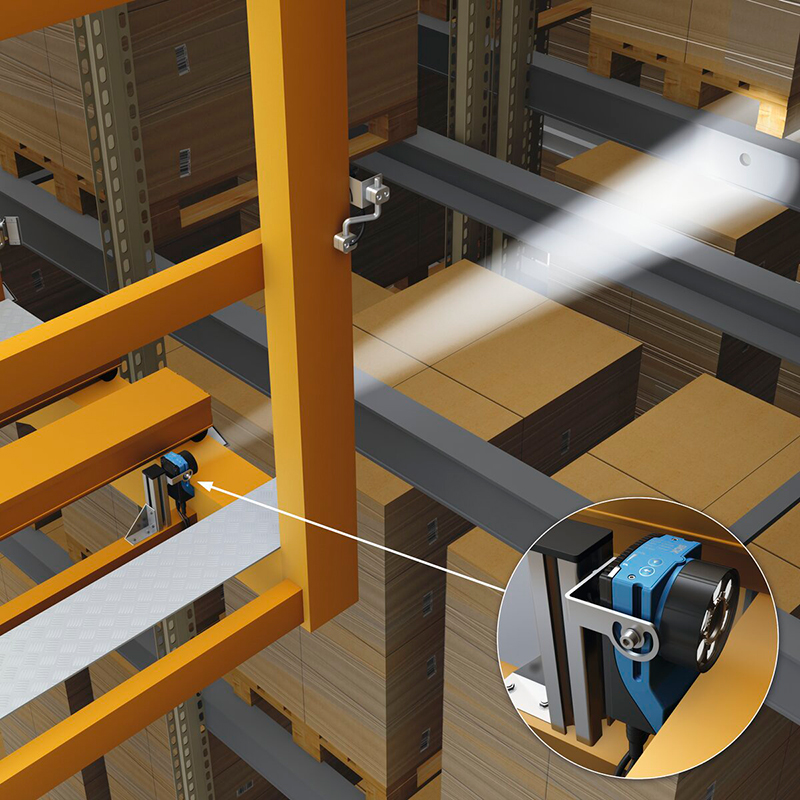

With SICK’s Rack Fine Positioning, you can use a pre-configured application and a programmable 2D vision sensor, InspectorP631, to gain more accurate and effective fine positioning of stacker cranes on the x and y axis.

Because the system is programmable, you gain added flexibility to accommodate your specific application.

More Precise Fine Positioning

Rack Fine Positioning is a dedicated pre-loaded app for solving fine positioning of stacker cranes or other automated storage and retrieval systems. The app works by locating pre-drilled holes or reflectors within the racks.

Two variants are available: one for single-deep racking and another for double-deep racking. Typically, double-deep racking cannot be accomplished without multiple cameras.

With Rack Fine Positioning, you can gain a high level of precision in both applications, with just one camera. The large measurement range allows for double-deep racking using the same sensor for both far and close range.

InspectorP Rack Fine Positioning supports precise positioning when putting in and removing load carriers from storage.

In doing so, positioning processes can be controlled both for single-deep applications, as well as combined applications with single- and double-deep racks.

The device is mounted to the ASRS. The device takes pictures when putting goods into and taking them out of storage and detects a hole or a round reflector as a positioning mark in the rack.

Using this positioning mark, the device sends a deviation of the current position of the ASRS from the target position to a higher-level control (e.g. PLC), which initiates rack fine positioning of the ASRS. This prevents load carriers from colliding with the racks.

High Precision Regardless of Rack Conditions

In addition, the Rack Fine Positioning system functions well even in poor conditions. Regardless of stains, damages to holes, or extraneous lighting, the high-quality image processing available with the InspectorP631 2D vision sensor enables reliable positioning inspection even in hard-to-reach places.

Both of these systems come pre-assembled and pre-configured for easy setup out of the box with pre-focused optics and lighting. That means you don’t need a vision expert on staff to get these installed.

A fine positioning system such as this perfectly complements existing rough positioning systems to allow more efficient use of rack space.

Article Topics

SICK News & Resources

ProMat C-Suite Interview with Dave Szczepanski: The field of robotics comes to life Leaders Q&A: Deploying Intelligent Sensors to Improve Warehouse Operations SICK and Aeva partner to offer 4D LiDAR to industrial sensing applications MODEX C-Suite Q&A: Tasha Bury, CFO, SICK, Inc. Take the Next Step on Your Digital Transformation Journey SICK introduces sensor solutions for mobile and stationary robotic applications Sensor Solutions for Mobile and Stationary Robotic Applications More SICKLatest in Warehouse|DC

Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs More Warehouse|DC