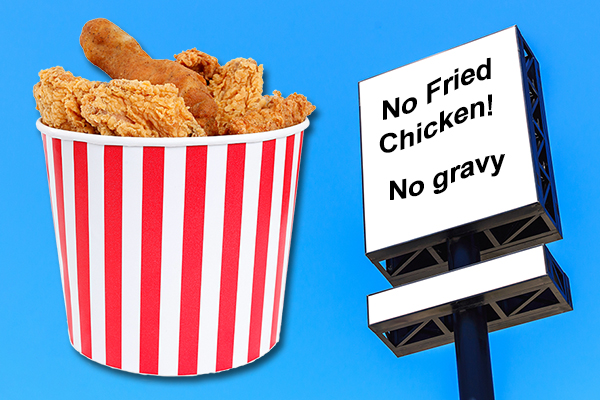

Cuts to KFC’s Logistics Network Result in Supply Chain Catastrophe

KFC, a fast food favorite, made headlines last month for suffering a chicken shortage that brought 900 restaurants in the UK to a halt...and recently, the chain announced it was suffering from a gravy shortage as well. Not ideal for a chicken restaurant.

No chicken and no gravy mean no customers. The whole debacle could have cost Yum! Brands Inc., KFC’s Parent company, up to £1m in losses per day. Not to mention a PR crisis that, despite a cheeky apology, will follow the company for years to come. What went wrong?

Don’t count your chickens before they’ve hatched

Chicken is prone to contamination by salmonella and other diseases, so transport is strictly regulated and must be done by refrigerated trucks.

The problem emerged after KFC switched its deliveries from Bidvest Logistics, a 3PL specialized in food delivery, to DHL and QSL. Bloomberg reports that KFC “pared back its logistics network to cut expenses.”

The epicenter of the crisis was KFC’s new distribution center, “which suffered a breakdown in its first week as the hub of the chain’s new cost-cutting strategy.”

Before getting anywhere near the restaurants, “tons of chicken spoiled there or in the backs of trucks that idled for hours as drivers awaited instructions that never came.”

The supply chain meltdown can be attributed to planning issues and risk management. They went from 6 distribution centers to 1. In a country like the UK, that can make sense, but perhaps with products that have a longer delivery cycle – not highly perishable products like chicken.

The issues they faced were apparently insurmountable, as the chain announced it would return at least a portion of its business (350 out of 900 locations) to Bidvest. As of today, 97% of the chain’s restaurants in the UK have re-opened.

Preventing supply chain woes

For consumers, it doesn’t make a difference how the chicken gets to their favorite restaurant. They expect it to be available when they want it. When it isn’t, they simply go somewhere else. What could’ve been done to prevent this crisis?

It’s important to realize that outsourcing doesn’t alleviate your responsibility to understand and analyze your own supply chain. For instance, one of our customers, a large food retailer in the UK, has a good relationship with their expert food suppliers, yet they still use AIMMS’ leading edge supply chain analytics to set the direction and mitigate risks. If KFC had used Prescriptive Analytics to test their assumptions and evaluate risks, they could’ve seen this coming and had a plan in place.

We’re here to help

Let us show you easy to Run “what-if-scenarios” in a safe trial environment. Using the correct technology before you execute on a new plan can help prevent inventory disruptions and revenue losses.

AIMMS likes to help companies with what we call The 4 R’s of Retail. It doesn’t matter if you are selling food, apparel or other consumer goods, it is critical to have the Right inventory at the Right place at the Right time and sell it at the Right price. Connect with us – we combine Real supply chain know how with innovative technology solutions to help your business make better decisions quickly and cost effectively before your business gets hurt.

Related Resource

What Are Companies Looking For in Network Design Technologies? New!

The purpose of this study is to understand the value proposition of supply chain network design technologies, including user satisfaction and key benefits and barriers to using these technologies. Download Now!

Article Topics

AIMMS News & Resources

The Post-Pandemic Warehouse & Distribution Center Workplace Assessing Supply Chain Planning: Ready for Today’s Challenges? Supply Chain Professionals Say Planning Process is “Somewhat Effective” Regardless of Technology Spending Too Much Time on Data Crunching and Not Enough on Resilient Planning Decisions Supply Chain Planning, Optimized | 3 AIMMS Case Studies Organizations are Betting on New Technologies to Improve Demand Forecasting Accuracy How is Demand Forecasting Changing? More AIMMSLatest in Supply Chain

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller More Supply Chain