New conveyors improve food maker’s process in less space

Vertical reciprocating conveyor adds flexibility with reduced footprint and maintenance.

Founded in 1921, UTZ Quality Foods is the largest independent, privately held snack brand in the United States, producing more than 3.3 million pounds of snacks per week (about half of which are potato chips) while operating more than 900 company-owned routes. To improve operational efficiency at its chip manufacturing facility in Hanover, Pa., the company installed a vertical reciprocating conveyor (VRC).

The unique VRC solution (Honeywell Intelligrated USS) consists of eight units that fit in small areas and avoid existing structural columns. Each unit conveys cartons of chips from a 36-inch elevation to a discharge height of 19.5 feet. A two-zone, zero-pressure accumulation conveyor shelf enables a Z-style configuration, meaning products of varying sizes enter, accumulate and exit on opposite sides of the conveyor modules. This optimizes the system duty cycle, transporting one or two packages per cycle depending on product length to boost throughput and minimize the stress on system components.

Motors are mounted near the bottom of each VRC unit to eliminate the need for any overhead maintenance activities, improving ergonomics and safety. The standard lightweight windows allow for product visibility and minimize visual obstructions from each 20-foot tall VRC within the facility. According to the facility manager, the VRC system allows UTZ to reliably handle carton sizes ranging from 9 inches to 42 inches in a small footprint, providing a steady stream of product to fuel downstream processes and seamlessly integrate with auxiliary systems.

Food and Beverage Products and Accessories

SK2000 closed back, tubular roll form columns

SK2000 closed back, tubular roll form columns

Strength enhancing features hallmark of tubular, roll form racking.

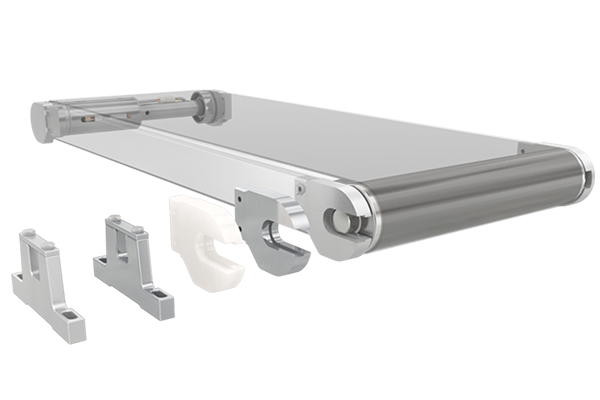

Belt Drives for the next generation

Belt Drives for the next generation

Interroll launches drum motor platform.

RX3i CPE 400 Outcome Optimizing Controller

RX3i CPE 400 Outcome Optimizing Controller

PLC increases manufacturing control and production optimization capability.

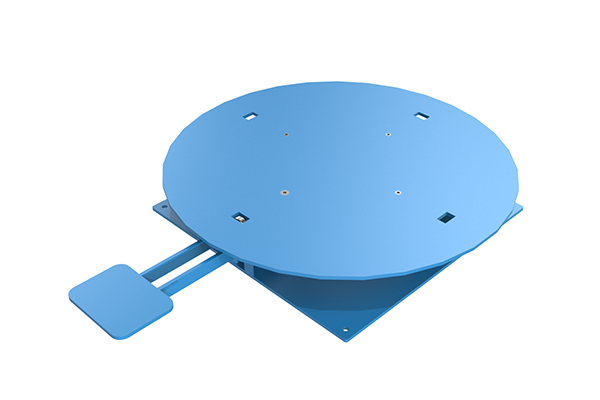

Conveyor turntables

Conveyor turntables

Conveyor turntables reduce manual materials handling errors.

KegFlow storage rack

KegFlow storage rack

Store, handle beer kegs safely in flow rack system.

ProGenic plastic pallets

ProGenic plastic pallets

Plastic pallets meet food, beverage, pharmaceutical product handling guidelines.