Make Purchase & Replenishment Planning Part of Your Supply Chain Competitive Advantage

Intelligent supply planning tools will help you gain an edge over your competitors with optimal inventory planning, reduced operating costs, and timely last-mile deliveries.

What Lies at the Core of Any Inventory-Led Business?

The ability to maintain optimal stock levels at all nodes of the supply chain and fulfill orders from multiple channels promptly.

And, the key to achieving this is real-time purchase and replenishment plans that are aligned with changing demand levels.

Hence, businesses these days leverage technologies like Artificial Intelligence ()AI and Machine Learning (ML) to manage complex supply chain networks and gain a foothold over the competition.

“According to Deloitte’s recent State of AI in the Enterprise survey, 94% of business leaders reported that AI is critical to success over the next five years.”

Download: Deloitte’s recent; State of AI in the Enterprise survey (free PDF)

They rely on automated inventory planning to adjust inventory norms in real-time when there are any disruptions and to stay on top of current market trends.

Further, businesses gain visibility across thousands of SKUs in multiple channels making inventory tracking and management hassle-free.

Let’s understand how our AI-powered demand prediction and inventory planning solution - Kronoscope, helped our clients leverage purchase and replenishment planning to improve operational efficiency and hit availability targets consistently.

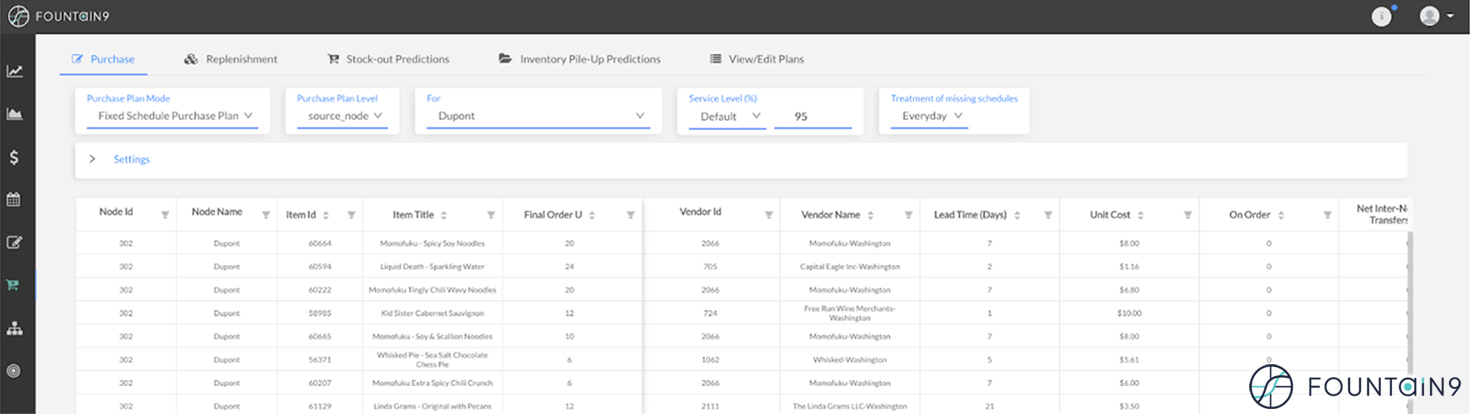

1. Purchase Planning for a Complex Network of Suppliers

Business Situation

The client is a US-based New Age Grocery Retailer that owns stores in multiple locations. They have over 1000 SKUs which also include raw materials/ingredients that are procured from nearly 1500 suppliers.

This was managed by a team of 40+ Store Managers manually. The process of mapping a myriad of SKUs with different suppliers and tracking their inventory levels on a daily basis became extremely tedious and complicated. The inability to track inventory at SKU levels made it difficult to maintain availability levels.

Further, it was challenging to evaluate multiple suppliers for various ingredients and decide on the ideal one according to specific business needs from time to time.

Our Solution

With Kronoscope, the client was able to automate comprehensive purchase planning at the most granular level (Ingredient x Store level) across the entire supply chain.

The purchase plans became more agile to adjust inventory and safety norms to align with the changing demand levels. They were able to have better visibility across their complex network of suppliers and evaluate them continuously. This way they were able to identify the ideal supplier in every business situation in order to ensure uninterrupted operations.

Results

The client was able to achieve higher visibility into their day-to-day purchase planning which helped them optimize their working capital. The real-time supplier evaluation and scoring ensured a smooth supply of inventory helping them achieve up to 30% faster fulfillment.

Furthermore, we simplified the order management process and reduced the time taken for purchase planning by 75%.

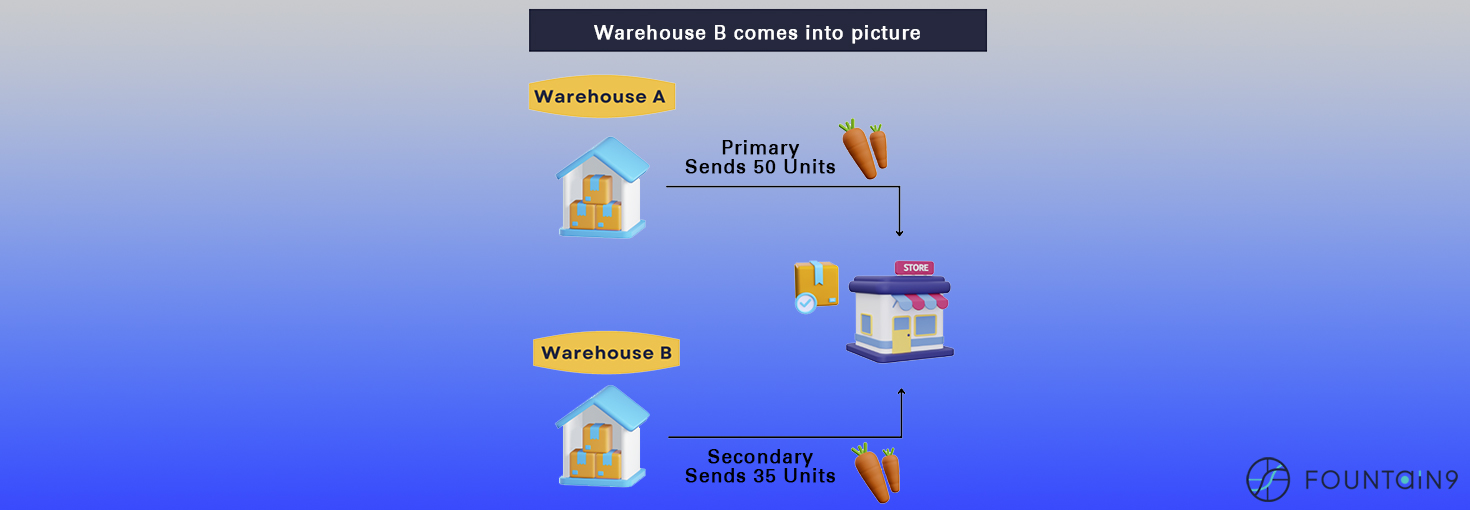

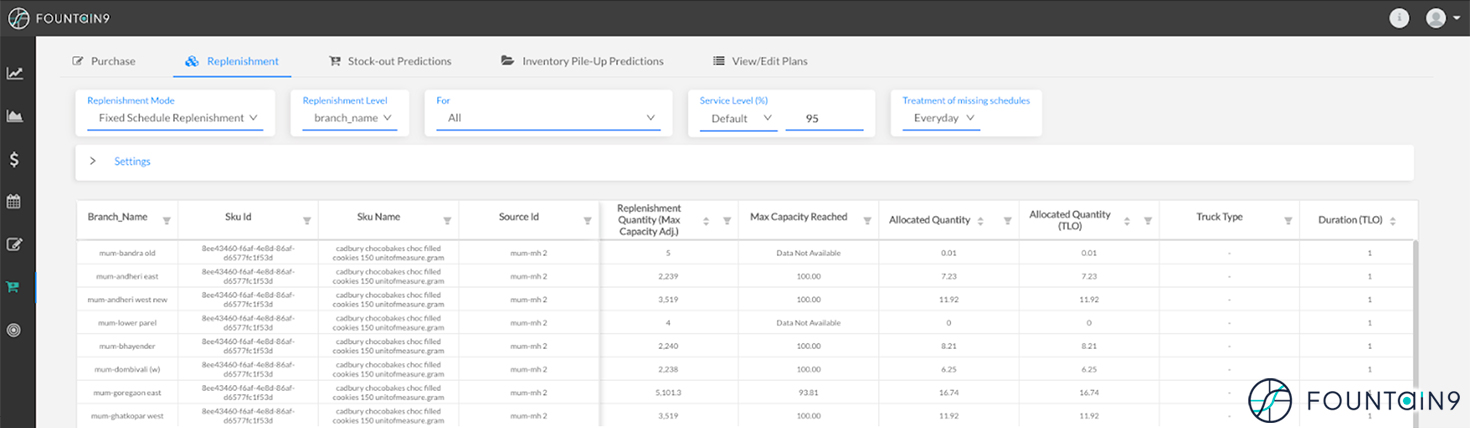

2. Replenishment from Multiple Sources

Business Situation

The client is a Quick Commerce company that delivers groceries on demand. It has a dark store business model to ensure quick last-mile deliveries. Dark Stores are essentially small storage places located close to customers to facilitate timely deliveries. It was taxing for the client to replenish these dark stores frequently in real-time and ensure consistent product availability. Hence, these dark stories were losing revenue due to out-of-stock instances which also led to a poor customer experience.

Our Solution

Kronoscope simplified replenishment planning at the SKU x dark store level across their supply chain by factoring in real-time changes in demand.

Let’s assume that Dark store A is mapped to Warehouse A which is its primary source of replenishment. Dark store A has a demand for 85 units of carrots while its primary source of replenishment, Warehouse A has only 50 units. Hence there is a shortage of supply.

Kronoscope quickly recommends replenishment of the remaining stock from the secondary source (i.e) Warehouse B. In this way, the dark store was prevented from an out-of-stock situation and was able to fulfill orders promptly.

Results

Kronoscope with its automated outlier detection was able to correct anomalies to give optimal inventory recommendations. This enabled the client to sell more by; reducing out-of-stock losses by 20 -30% and enhancing customer experience by increasing the availability levels by up to 25%.

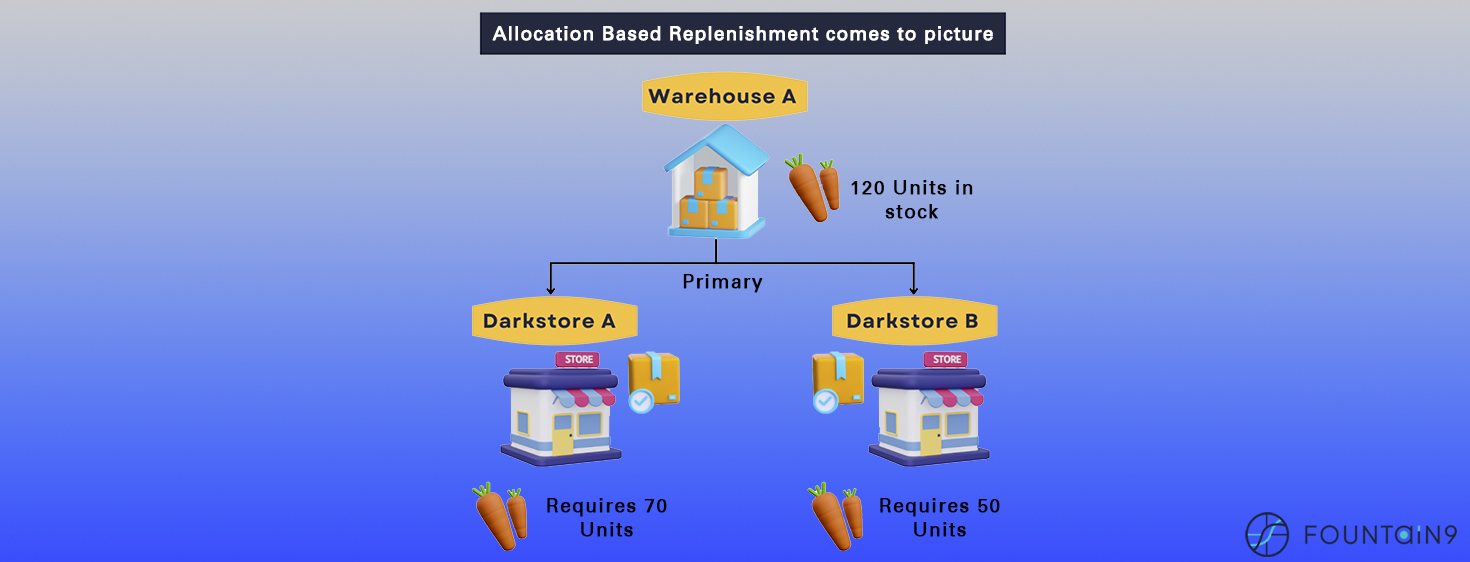

3. Allocation-based Replenishment

Business Situation

The client is a grocery delivery company with a dark store business model. They have a complex supply chain network with one warehouse mapped to several dark stores. They encountered several instances where they were in limbo when it came to determining the optimal replenishment quantities for different dark stores. It was also critical to consider the short shelf life of the SKUs while planning inventory so that they don’t end up with inventory wastages.

Our Solution

Let’s assume that dark stores A and B are both mapped to Warehouse A which is their primary source of replenishment. Darkstore A had a demand for 90 units of carrots and Darkstore B had a demand for 75 units. But Warehouse A has only 120 units of Carrots in stock.

In this situation, secondary warehouse B also has a longer lead time due to which Kronoscope recommended an allocation-based replenishment.

Here, a typical procurement process that lacks visibility across different nodes would have carried out a full replenishment of 90 units at Darkstore A, which would have led to either an inventory pile-up in dark store A or a stock out in dark store B.

Hence the system recommends a need-based fulfillment of 70 units of Carrots to Dark store A and 50 units to B. This is recommended based on the Current Inventory Runway and Demand levels of both dark stores A and B. This allocation helped ensure that both dark stores were optimally stocked to hit their availability targets until the next replenishment cycle happens.

Results

This helped in making informed replenishment decisions to fulfill different business needs in real-time. The client was able to bring down inventory wastage by 15 - 40%& by stocking only what would sell. Further, the proactive alerts on inventory pileups helped them liquidate excess inventory quickly and judiciously use the capacity of dark stores.

In summary, intelligent supply planning tools like Kronoscope help you gain an edge over your competitors with optimal inventory planning, reduced operating costs, and timely last-mile deliveries. Further, automating your inventory planning leaves you more time to enhance your customer experience with innovative products and services.

About the Author

Niki Khokale is the co-founder & CEO of Fountain9 with over 10 years of experience in Operations Planning and Machine Learning. With Fountain9, she is bringing the power of machine learning to end food waste for food and beverage companies. She has raised funding from reputed investors such as Y Combinator, 021 Capital, Harvard Seed Fund, and impact venture fund Blue Impact Ventures.

Related Resources

2% Increase In Revenue For Meat Brand In the US With Unconstrained Demand Sensing

Learn how to break down departmental silos and design resilient and sustainable supply chains. Download Now!

.

Cracking The Inventory Planning Code: The Omnichannel Way

Download the whitepaper to know 3 critical things that can help you design sophisticated inventory planning processes to reduce your inventory costs & wastages. Download Now!

The Definitive Guide to Demand Planning

Download this whitepaper to discover 10 best practices that are crucial for accurate demand predictions. Download Now!

More Resources from Fountain9

Related Article: Understanding the Essence of Supply Chain Networks

Article Topics

Fountain9 News & Resources

Make Purchase & Replenishment Planning Part of Your Supply Chain Competitive Advantage 2% Increase In Revenue For Meat Brand In the US With Unconstrained Demand Sensing Understanding the Essence of Supply Chain Networks Cracking The Inventory Planning Code: The Omnichannel Way The Definititive Guide to Demand PlanningLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain