A Blueprint for Supply Chain Network Design Success

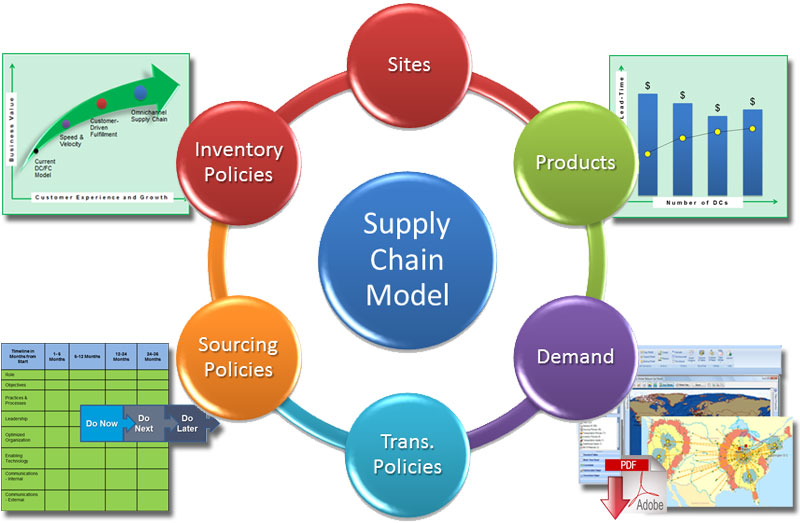

The growth of global markets, increasing customer expectations, rising costs, and more intense and diverse competitive pressures are driving the development of new supply chain strategies and intricate network designs.

Supply chain optimization, like lifestyle changes, do not happen overnight.

They are ongoing processes marked by continuous improvement and a few ups and downs. But in both situations, it’s essential to have a blueprint for success.

I recently had the pleasure of participating with Supply Chain Management Review in a Webcast called “A Blueprint for Supply Chain Optimization.” It covers the steps to take before embarking on a network design and how it’s really a process instead of a project (video above).

Ensuring flexibility is so important to meet the expectations of today’s Omni-Channel customers – as is the right technology and modeling.

To listen to the Webcast, click on the video above.

Judging by some of the follow-up questions I received from attendees, they are taking a serious look at their own blueprints for supply chain optimization. Here’s a few of the most interesting questions and answers.

Q: “How are the models taking into consideration government policy changes such as the Affordable Care Act?”

A: With the Affordable Care Act, you could see an impact to the cost of driver labor, which is an input not a model constraint. One option is to apply a stair-step approach with the labor component you are modeling. A second option is to apply limited resources at one cost and then more expensive at a different cost. But this will likely result in some driving volume to use all of the lower labor costs. So please make sure you have a stable model prior to this run being incorporated.

Remember that the model is a strategic direction – and that process and complementing the model to incorporate will yield the best results.

Q: “Are you using cloud-based supply chain collaboration/visibility software?”

A: Yes, but in order to really benefit from cloud-based tools, you must consider a couple of constraints. First, do you need to allow the cloud to run the model because it is too large for a PC-based tool to handle? Second, should you purchase the software as a long-term planning tool? If you purchase the software, you can set it up to fully incorporate the power of the cloud to link to files from a global basis and to allow for information to be refreshed continuously, thus starting the develop of a continuous improvement process.

Both are still viable solutions that require a detailed model and people to update and run scenarios.

Q: “Real execution during peak holiday periods is very messy with lots of expedites and drop-ships, etc. How can we exclude the noise to come up with an optimal model?”

A: Instead of cleaning to get rid of the noise, have you asked how much the noise contributes to overall costs? Is this “noise” simply the understanding of your business and what to model? Is it critical in understanding if the model timeframe should include or exclude this noise? At a minimum, consider setting the model up on an inbound to understand how to allow a configuration to execute the model with drop ships and without. Consider doing the same with the expedited orders. And make sure the model you will be using can accomplish this task.

In most models, you should have some user-defined fields to allow for this to occur. You can also adjust service to a standard level during this period to help reduce the noise. However, fulfillment and shipping policies must be adjusted and adhered to in order to reflect controlled windows, or backorder rushes, expedites, split shipments, and so on.

The key here is that all these scenarios must be modeled to reflect reality.

Are you running across similar questions in your supply chain operations? How are you updating your blueprint to meet changing customer demands?

Related: A Blueprint for Supply Chain Optimization

Article Topics

Blue Yonder News & Resources

Women in Supply Chain: Ann Marie Jonkman of Blue Yonder Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Frictionless Podcast: Understanding Your Supply Chain Goals with Ann Marie Jonkman Blue Yonder announces acquisition of flexis AG Supply Chain Management (SCM) applications keep the supply chain humming How Collaborative Efforts Can Enhance Reverse Logistics More Blue YonderLatest in Supply Chain

Apple Accused of Multiple Human Rights Violations UPS Struggles in First Quarter With Steep Earnings Decline How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace More Supply Chain