Improving Warehouse Processes & Efficiency with Autonomous Mobile Robots

Warehouse professionals know the feeling – the pressure is high,with more products, faster delivery times, and less staff, supply chains must operate more efficiently than ever before, they must be flexible and scalable but also cost-efficient - so, how can you tackle this seemingly impossible task?

Autonomous Mobile Robots

One of the technology trends addressing these issues in the market is autonomous mobile robots (AMRs).

As the name suggests, these robots move autonomously through a warehouse or fulfillment center, navigating their way with a digital map, sensors, cameras, and safety mechanisms while continuously updating the map of their environment.

Should an obstacle be in their way, they simply find a way around it – without help, and digitally notating the location of the obstruction. This makes them an incredibly flexible solution for the dynamic environment of a warehouse.

How can AMRs help me solve my warehouse challenges?

With little personnel available in the warehouse, AMRs are here to support warehouse workers rather than to replace them. They allow you to increase productivity simply by taking over the most repetitive, time-consuming, and dangerous tasks.

This means your employees’ work will become easier, safer, and free them up for more valuable tasks and make them more productive. AMRs target movement-related workflows, which means that the warehouse employees can perform more work while taking fewer steps, letting the robots take over the movements.

So, what tasks can they take on? You may want to use them for handling picking and put-away of goods, sorting objects within the warehouse, or/and support workers with manual handling.

Besides that, they can also be used for:

- Bulk material movement

- Components shuttling

- Goods-to-person fulfillment

- Piece picking in fulfillment

- Sortation

- Pallet picking

How do AMRs take over tasks in practice?

The way you use the robots depends on what you use them for – let’s have a look at some examples.

Imagine peak season: in a manual environment, an army of pickers would pushcarts throughout the facility fulfilling orders. At the end of the batch of orders they are working with, they push the completed carts to the packing locations. One approach to improve this workflow is with swarming bots. With those, such as Locus Robotics, additional robots can be added to the fleet to create short-term increases in capacity.

In this scenario, the capacity of the everyday labor increases and can be supplemented with fewer temporary laborers, who are fully trained in hours - rather than days or weeks. Swarming bots navigate to meet workers at the picking locations and improve the flow of goods. That means your employees can concentrate on picking and will neither be pushing carts nor wasting time on additional tasks.

An additional approach is the Goods-to-Person or G2P methodology. In this scenario, robots shuttle racks of goods to pickers who remain in stationary pick modules. This methodology significantly increases picker performance. It also maximizes the throughput of the pick operation by eliminating the walking that pickers would otherwise have to do since the work is brought to them. The same holds true relative to peak: instead of bringing in an army of temporary labor, it becomes easy and cost-effective to add a smaller number of temporary workers or simply add a shift.

How can I benefit from using AMRs in the warehouse?

Since they take over time-consuming tasks such as moving around the warehouse while leaving value-added tasks to your staff, they increase productivity. Plus, having all product information available to the worker on a screen such as what the product looks like and where to find it reduces errors – and customer dissatisfaction due to wrong deliveries!

As you can hire robots as part of a Robotics-as-a-service (RaaS) offering, you can flexibly scale up and down as your demand dictates. Hire more when it’s busier, return them when business calms down. Adding them for a peak is easy, too – they just need to be connected to your network (assuming the system is already in place). This makes them highly cost-effective, especially as you don’t have high upfront costs related to fixed automation.

Besides this, they’re easy to integrate without disturbing operations and get to know their surroundings quickly while adapting their movements accordingly.

Lastly, you can support your small workforce – which means you can more effectively deal with labor shortages and seasonal peaks.

In a world where flexibility and speed are key while online sales are growing, finding people to work in the warehouse is challenging. Recently, the pandemic has also added the additional challenge of reducing contact within the warehouse. That’s what makes AMRs in the warehouse such an ideal technology, helping warehouses stay competitive and companies to succeed.

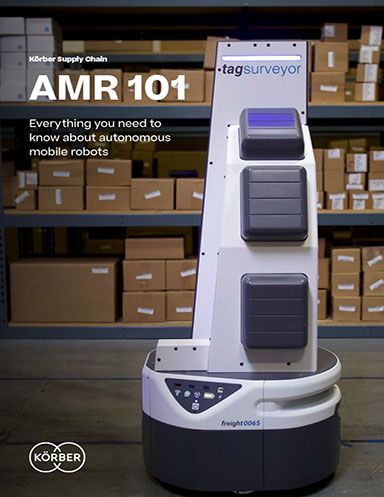

Download the Whitepaper AMR 101 – Everything You Need To Know About Autonomous Mobile Robots

About the Author

John Santagate leads Körber Supply Chain Software as the Vice President of Robotics. He drives the strategy for autonomous mobile robotics, warehouse robotics, and the robotics partner network. As a key component of Körber’s end-to-end solutions, John ensures his technologies drive customer success and integrate seamlessly with the broader Körber portfolio.

Related Resources

AMR 101 - Everything You Need To Know About Autonomous Mobile Robots

Autonomous Mobile Robots improve logistics and operations efficiency by supporting floor operations, transportation, and processing, and rather than replace people entirely, AMRs should take on the most repetitive, time-consuming, and dangerous tasks, to save on manual labor. Download Now!

Article Topics

Korber News & Resources

Supply chain technology takes care of the heavy lifting for Titan BrandsLatest in Supply Chain

Ranking the Top 20 Women in Supply Chain TIm Cook Says Apple Plans to Increase Investments in Vietnam Talking Supply Chain: Doomsday never arrives for Baltimore bridge collapse impacts Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process More Supply Chain