Hudson’s Bay Company Unveils First-in-Canada Robotic Fulfillment System

Hudson’s Bay Company unveiled a new state-of-the-art robotic fulfillment system, which propels HBC’s Scarborough Distribution Center to the forefront of e-commerce distribution technology.

Hudson’s Bay Company's highly innovative distribution center is the first of its kind in Canada and showcases some of the most advanced automated distribution technology in the retail sector.

This distribution center will contribute to a seamless experience for customers and further support Hudson’s Bay’s all-channel retail capabilities.

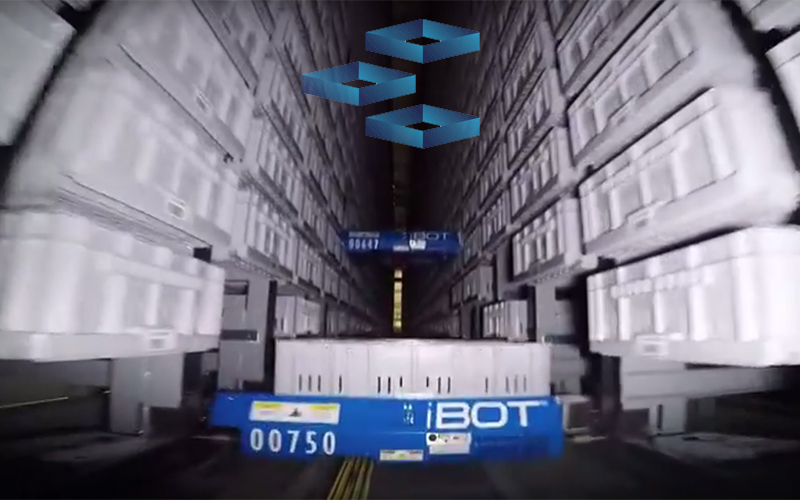

The OPEX Perfect Pick™, a unique, automated, high-speed, goods-to-man, piece picking solution based on proven iBOT™ delivery technology, is the largest Perfect Pick case shuttle system ever built and is 12 to 15 times faster than a traditional manual process.

It features 16 200-foot long aisles, utilizes the entire vertical height of the building, can hold more than one million units of inventory and can process roughly 4,200 customer orders per hour.

Two custom-built document handling robots automate insertion of packing lists, while 15,000 feet of conveyor and a fleet of approximately 300 autonomous robotic delivery vehicles - iBOTs - move inventory for storing and shipping.

The best-in-class technology will enable the company to deliver orders three times faster than distribution centers using the next best robotic technology.

The investment to upgrade the entire distribution facility was in excess of $60 million.

“Our customers will benefit from the country’s fastest order shipping system,” said Jerry Storch, HBC’s Chief Executive Officer.

“We are proud to be the first to bring this industry-leading technology to Canada, in time for the busy holiday season. This investment in our Scarborough Distribution Center creates an e-commerce technology hub and allows us to expand our e-commerce business, which is a key component to our all-channel strategy.”

The 752,000 square foot Scarborough Distribution Center supports e-commerce for HBC’s Hudson’s Bay department store. More than 300 full-time associates are employed at the center.

About Hudson's Bay Company

Hudson’s Bay Company is one of the fastest-growing department store retailers in the world, based on its successful formula of driving the performance of high quality stores and their all-channel offerings, unlocking the value of real estate holdings and growing through acquisitions.

Founded in 1670, HBC is the oldest company in North America. HBC’s portfolio today includes ten banners, in formats ranging from luxury to better department stores to off price fashion shopping destinations, with more than 470 stores and 66,000 employees around the world.

In North America, HBC’s leading banners include Hudson’s Bay, Lord & Taylor, Saks Fifth Avenue, Gilt, and Saks OFF 5TH, along with Find @ Lord & Taylor and Home Outfitters. In Europe, its banners include GALERIA Kaufhof, the largest department store group in Germany, Belgium’s only department store group Galeria INNO, as well as Sportarena.

HBC has significant investments in real estate joint ventures. It has partnered with Simon Property Group Inc. in the HBS Global Properties Joint Venture, which owns properties in the United States and Germany. In Canada, it has partnered with RioCan Real Estate Investment Trust in the RioCan-HBC Joint Venture.

Related Article: Numina Group Announces the Release of a Full Featured Warehouse Management System, WMS

Related White Papers

Five Ways to Optimize Your DC For E-Commerce Fulfillment

The rise of e-commerce and multi-channel fulfillment has caused distribution centers to experience ever-growing numbers of stock-keeping units and more inventory turns, up to an average of nine in 2015. Download Now!

Automating or Modernizing Your DC will Reap Great Long Term Savings

Modernizing a distribution center requires significant investment, so businesses often choose to postpone or avoid expansion of warehouse capabilities and functionality. Download Now!

The Return-on-Investment of Voice Picking

To produce a solid business case - replete with ROI, internal rate of return, payback period, net present value and similar metrics - one must first quantify the financial benefits that reduce existing hard-dollar costs in labor, operating expenses, materials, inventory and fixed assets. Download Now!

Article Topics

CubiScan News & Resources

Pocket Nurse boosts productivity with better connectivity Some new twists on an old measure Voice efficiency meets smart pallet builds Top 20 Automatic Identification and Data Capture Suppliers 2021 60 Seconds With… Randy Neilson & Stephen Pickfield of Scan, Label, Apply, Manifest (SLAM) Cubing and Weighing: Right on the money A new take on dimensioning in the DC More CubiScanLatest in Warehouse|DC

North Carolina Welcomes Amazon’s Newest Mega-Warehouse SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics More Warehouse|DC