How Weather-Adjusted Estimated Time of Arrival Can Transform Your Supply Chain

According to the Federal Highway Administration, Weather is responsible for 23% of all roadway delays, causing over 32 billion lost vehicle hours per year and costing trucking companies between $2.2 and $3.5 billion dollars.

Weather-Adjusted ETA's

Freight delays have a massive impact on the entire supply chain – they spike operating costs, force overtime pay, decrease productivity, and, most importantly, leave customers dissatisfied and reluctant to work with you again.

Weather is responsible for 23% of all roadway delays, causing over 32 billion lost vehicle hours per year and costing trucking companies between $2.2 and $3.5 billion dollars (Federal Highway Administration).

The Hidden Cost of Weather Inaction

For supply chain and logistics companies, the cost of not accounting for future weather-related delays is high, both financially and logistically.

Unexpected delays in transit and late deliveries due to weather events can result in:

- Disruptions to work shifts and hours of unloading personnel

- Time and temperature-sensitive products spoiling

- Additional fuel, oil, and truck operational costs

- Extra in-transit inventory holding costs

- Interrupted workflows at unloading bays

- A disturbed production schedule and lower overall productivity

- Late-fees and lost customer retention

An Urban Mobility Report from The Texas Transportation Institute (TTI) estimated that the Tampa Bay area had an annual truck delay of 3,223,00 hours in 2011, costing the industry roughly $246 million. The weather alone caused 23% of those delays, costing $56.6 million.

That same report estimated that in the year 2000, the imputed operational cost of delays alone was about $70 per hour for the southern United States, which would translate to roughly $100 per hour today (FDOT).

Furthermore, a study done by researchers at Texas A&M and the University of Wisconsin showed that delays to shippers cost $34 per hour in the year 2000, which would translate to about $50 per hour today. The study also noted that these costs can fluctuate significantly based on the type of product being shipped.

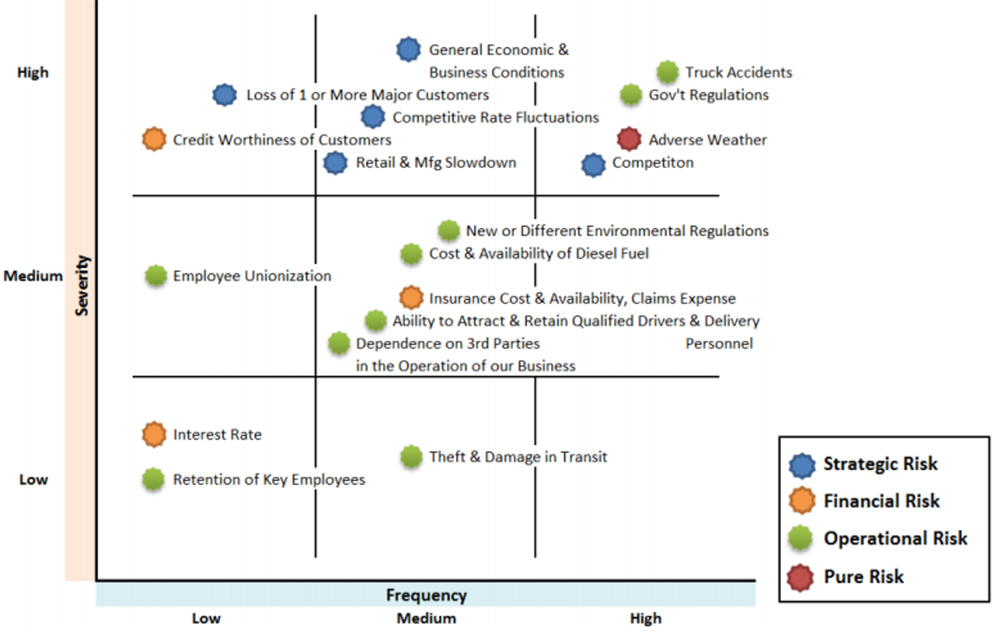

A 2010 risk evaluation report on J.B. Hunt, one of the largest trucking carriers in the world, identified Adverse Weather Conditions as the only “pure risk” of their 18 total “major risks.”

A pure risk in this case is a variable that cannot be controlled and leads to unpredicted losses each year. The evaluation highlighted major financial losses in both physical assets and productivity, with $26 million attributed to weather-related trucking accidents, and a “significant amount of lost productivity.”

Risk Map

The report goes on to say adverse weather conditions are a “high severity, high frequency, and continuous risk for J.B. Hunt”

Their form 10-k stated, “Extreme or unusual weather conditions can disrupt our operations, impact freight volumes and increase our costs, all of which could have a material adverse effect on our business results.”

Proactive Action Requires more than Real-Time Data; it Requires Predictive Data

In order to avoid accidents and delays, supply chain and logistics companies need proactive knowledge about when and where they are likely to occur.

Though consumer and business-facing routing tools such as Google, TomTom, and HERE provide real-time ETA information, they do not account for weather-related delays outside of real-time.

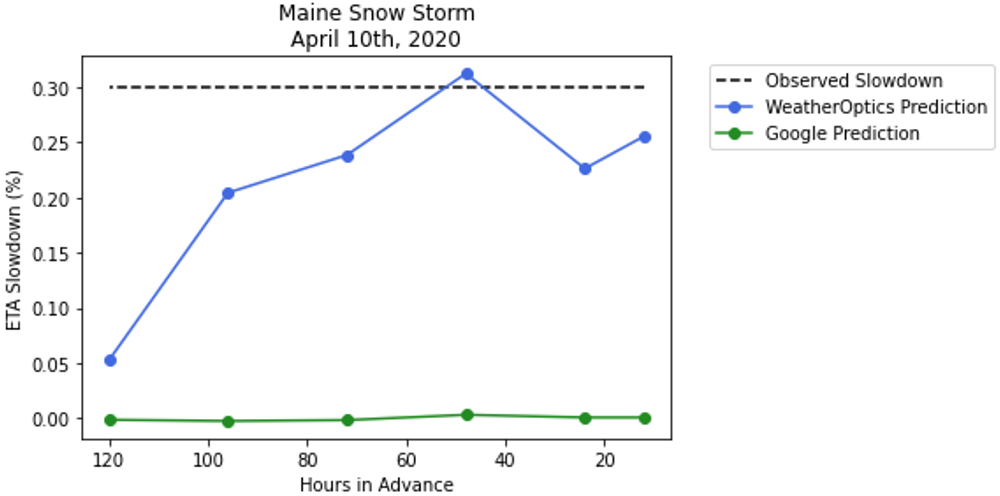

RightRoute vs Google During a Snowstorm in April 2020

Over the last decade, there has been a huge movement towards end-to-end supply chain visibility in order to improve ETA accuracy and cut down on delays. Freight visibility platforms like FourKites and Project44 are two of the most prominent companies shining a light on nuances in the supply chain process in order to produce the most accurate predictive ETAs.

According to a recent Project44 report, 70% of consumers want the ability to track the progress of shipments and 47% want an accurate delivery time estimate.

Calculating the ETA of a single shipment is complicated, with hundreds of moving pieces to account for between the shipper, supplier, and carrier. The time it takes for a commercial truck to drive from Point A to Point B can fluctuate significantly based on real-time traffic, hours have driven, time of day, operational inputs, and more.

Despite new cutting-edge technologies, the supply chain industry has been slow to incorporate predictive weather data into their Transportation Management Systems (TMS).

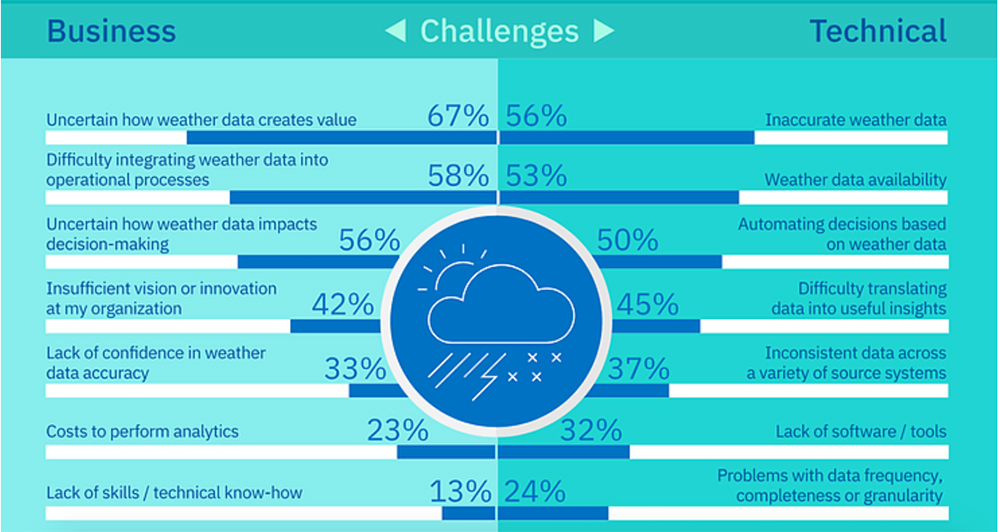

This is in part due to a lack of understanding about how different weather types in different parts of the country affect the movement of goods, and how weather impact can be applied to thousands of future and ongoing routes. A recent IBM study showed that 45% of technical executives have difficulty translating weather data into useful insights, and 50% have difficulty using weather data to automate decisions.

Even accurate weather data has proven to be difficult to adapt for supply chain and logistics companies. Knowing there is a 70% chance of snow in 3 days is less actionable than knowing how much time will be added to a 4-day route shipped with a 5-axel truck going from New Orleans to Seattle.

So What's Stopping Executives from Gaining Better Weather Insights?

Source: The IBM Institute for Business Value

The same study highlighted a number of other reasons supply chain executives might shy away from integrating weather data:

- 67% of business executives are uncertain how weather data creates value

- 58% of business executives have difficulty integrating weather data into existing operational processes

- 56% of executives are uncertain how weather data impacts decision-making

A Weather Solution Built for Supply Chain and TMS

In August 2020 WeatherOptics launched RightRoute, the first-ever weather-adjusted ETA API for the supply chain and logistics industry.

After working alongside a global telematics provider and other industry leaders, we developed a solution that can accurately adjust the ETA of a shipment based on future weather conditions, location-specific impact, and vehicle attributes.

RightRoute is built to bridge the barrier between weather data and transportation impact because it provides clear insights that are easy to ingest into existing software to improve ETAs and overall visibility.

To return a weather-adjusted ETA, all RightRoute needs is the origin, destination, and time of departure. The output includes expected speed reduction of the shipment for different routing options, flagged routes that are at high risk of seeing accidents or road closures, and individual instances of slowdowns along the way.

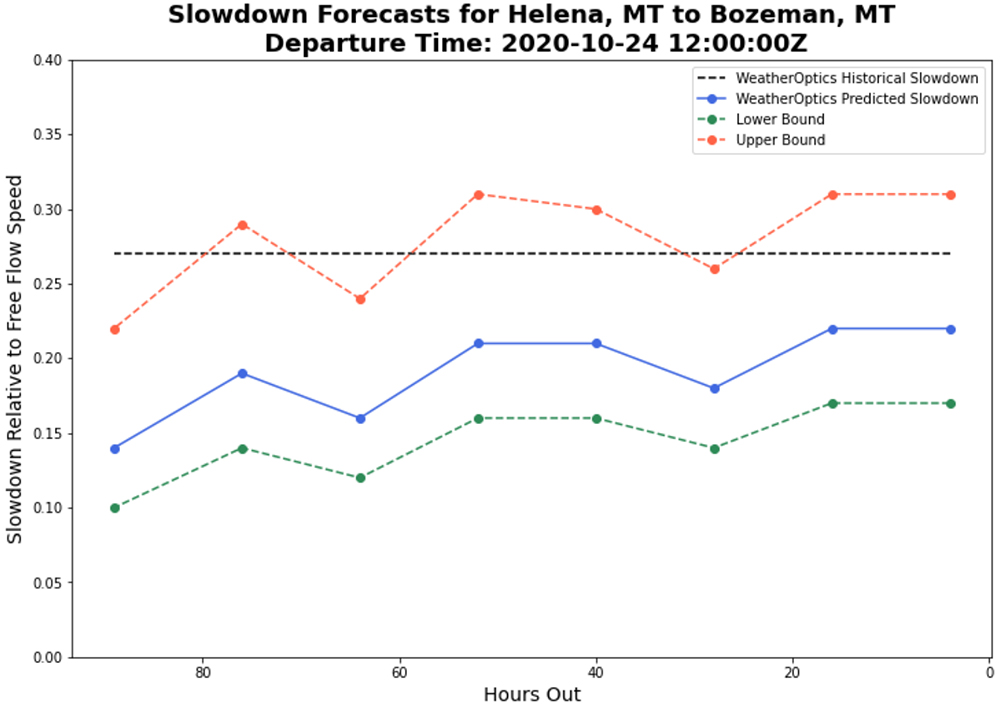

WeatherOptics RightRoute Verification Study

Key Features:

- Weather-adjusted ETAs with the actual percentage slowdown from normal due to current and future weather conditions

- Ability to integrate with any existing non-weather adjusted ETA, TMS or route provider to improve transit time accuracy and overall visibility

- Detailed overview of expected weather along routes, including when extreme weather is likely to cause accidents and road closures

- Ability to account for specific vehicle attributes such as vehicle weight, length, and load-type

By leveraging and integrating RightRoute into existing Transportation Management Software, you'll see improvement from day one:

1. Improve visibility and delivery window accuracy

a. Multiple days notice on potential shipment disruptions

2. Increase driver safety and accident prevention

a. Accidents cost between $20 and $40 million per year on average

3. Maximize efficiency when delays are expected

a. Proactive changes in the workforce, less overtime pay, and reduced operating costs

4. Optimize inventory at all times

a. Appropriate stocking before inclement weather

5. Increase customer retention

a. Transparency about potential delays or avoiding them altogether

As demand for faster deliveries increases, so will technology that addresses potential disruption.

Though weather can be unpredictable, it does not have to be unmanageable. We now have the tools to ensure supply chain and logistics companies can be proactive instead of reactive when it comes to disruptive weather.

Learn more about how you can leverage RightRoute and our Weather Impact APIs here.

Related Resource

Could Climate Become The Weak Link In Your Supply Chain?

Supply chains and the infrastructure that supports them are designed for a stable climate, but as hazards evolve, it will be necessary to increase investment in adaptation, possibly at the expense of efficiency. Download Now!

More Resources on Weather-Related Risk Management

Article Topics

WeatherOptics News & Resources

How Weather-Adjusted Estimated Time of Arrival Can Transform Your Supply Chain Could Climate Become The Weak Link In Your Supply Chain?Latest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain