How to Change Your Supply Chain Inventory Planning Process

Change is hard for any organization, but Princess Auto, a nearly 90-year-old Canadian hard goods retailer, changed its collective thinking and brought a new level of efficiency to its inventory planning and how product flows to its customers.

Change and Irrelevance

Eric Shineski, retired general says;

“If you dislike change, you’re going to dislike irrelevance even more.”

In business, the only constant is change. Given the complexity, connectedness, and immediacy of today’s modern world, it’s safe to say that you, and your organization for that matter, need to become very good at change. Sure, we’ve attached fancy and modern names to it - pivot, for example - but the bottom line is we all need to excel at changing our minds, our worldviews, and work and personal habits.

But change is hard. To highlight just how hard, consider the difficulty people have in changing their habits when faced with a life-threatening situation - people who require coronary artery bypass surgery. After the surgery, patients are told that they need to change their lifestyle to maintain their health - stop smoking, stop drinking, stop overeating, start exercising and reduce stress.

Yet, study after study confirms the dismal results - within two years of the surgery 90% have not changed their lifestyle. Those are odds of about nine to one against you making the change, even in a life and death situation.

It’s no surprise then that business change has similar odds. After all, we’ve eventually realized that business change is really about people - the ability to change not only our own minds but also help others change theirs as well. Joe Jackman, in his excellent book, “The Reinventionist Mindset,” speaking about business transformation and reinvention summed it up perfectly when he wrote:

“Change is a human endeavor with a business consequence.”

Business change and transformation are about people and, essentially, the inner workings of the brain.

This article outlines the approach and learnings that Princess Auto Ltd used to completely transform how it plans and manages the supply chain and the flow of inventory from the supplier to the consumer. It will provide details on how this 87-year-old company was able to change the collective thinking, or mental model, of the company utilizing many of the principles and ideas outlined in “The Catalyst,” a new book about the process of change by Jonah Berger.

Before and After Change

Before the change. Princess Auto Limited (PAL) is a Canadian hard goods retailer with 49 stores located from coast-to-coast, selling a wide variety of products that are targeted to help customers - the “figure-it-outers” - do, fix, tinker, and make things. The stores and online portal offer their predominately male customers approximately 15,000 products, sourced from more than 400 merchandise vendors located around the globe, flowing through a network of three distribution centers.

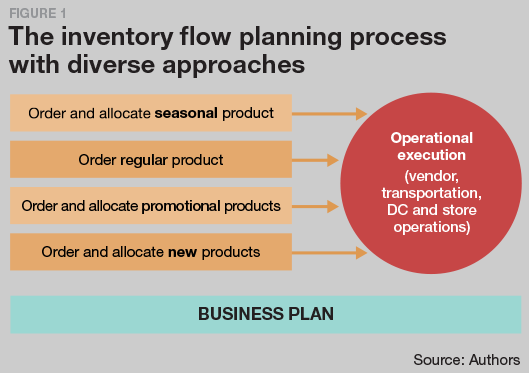

Prior to fundamentally changing the planning process, PAL planned the flow of inventory from the supplier to stores like many retailers - thorough a combination of re-order points for every product at every store, augmented with a collection of home-grown spreadsheets and analytical tools. The inventory flow planning process was really a collection of unique approaches and tools to support several planning scenarios - including key ones like promotions, seasonal and product introductions, and discontinuations.

In reality, these processes weren’t linked or driven by a shared view of the future - independently developing forecasts and plans for their teams and departments, very loosely connected to the goals and aspirations of the business, as depicted in figure 1 below.

After the change. In 2015, PAL realized it needed to improve supply chain performance and, as a result, embarked on an ambitious plan to improve planning capabilities, agility, inventory flow, and ultimately, store in-stock performance. The resulting design and implementation helped transform the company and its supply chain to be consumer-centric and integrated from store to supplier.

As a result, store in-stock and inventory performance consistently hovered around industry benchmarks - not surprising because the planning processes were consistent with current industry practices and thinking. In addition, when things didn’t go as planned it was difficult to pinpoint where things went wrong and almost impossible to fix and learn from it because so many fingers were in the proverbial pie, so to speak.

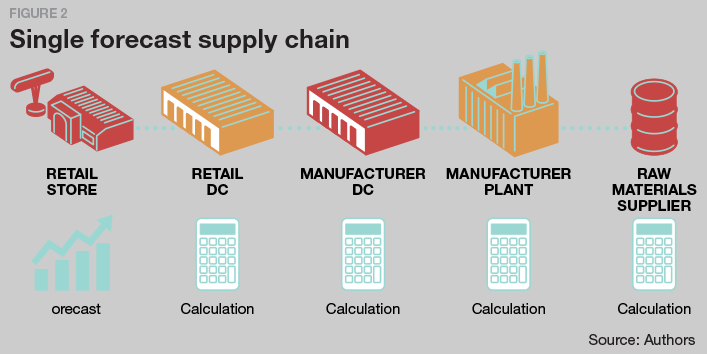

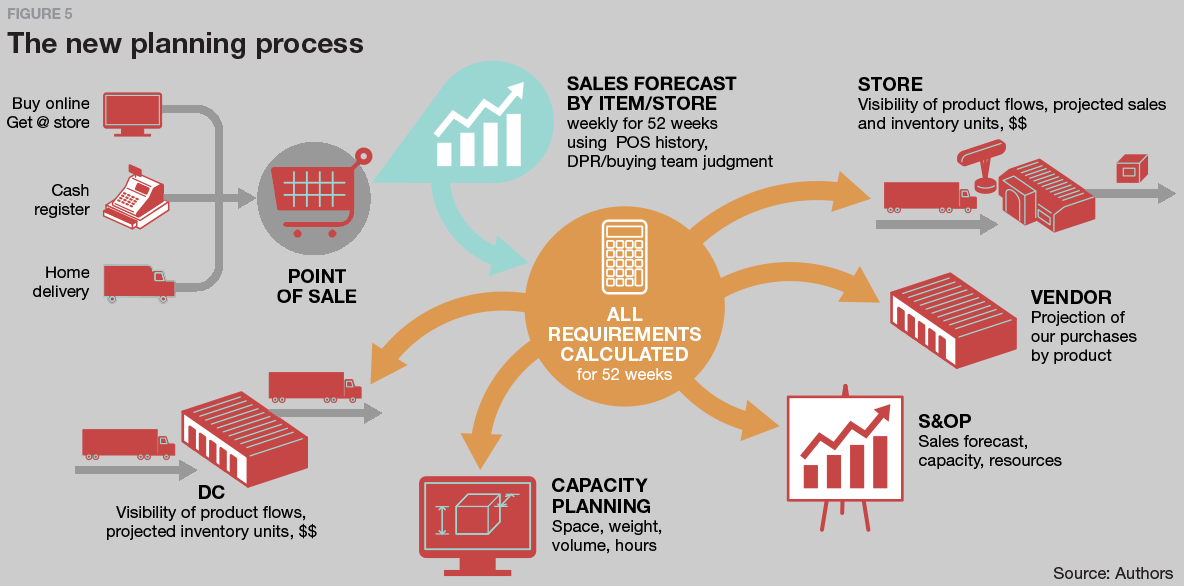

The team would design and implement new demand and supply planning processes for all products, all channels, all stores, and suppliers simply by only forecasting sales at the store/product level and calculating and cascading a series of integrated time-phased replenishment plans from store to factory - commonly referred to as flow casting.

The only forecasting that would occur in the entire, integrated supply chain would be consumer sales, for a rolling period of 52 weeks, by item/store (or website).

Adhering to the principle of “never forecast what you can calculate,” all resulting time-phased inventory/supply projections would be continuously calculated.

This is based on the forecasts and the inventory and ordering rules and shared, as depicted in figure 2.

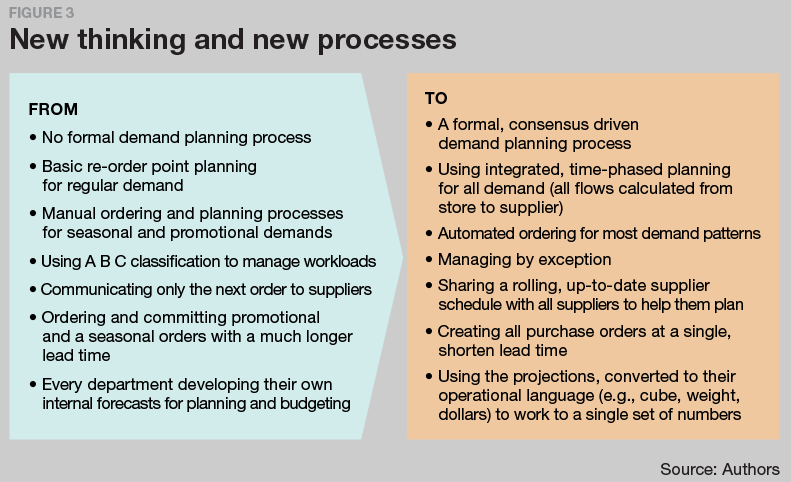

In the process, the project team helped people change their thinking and behaviors in order to plan to a single set of numbers.

This includes sales planning, replenishment planning, operations planning, financial planning, and supplier collaboration and integration.

The change in process and thinking is outlined in figure 3 to the right.

Changing the Mental Model

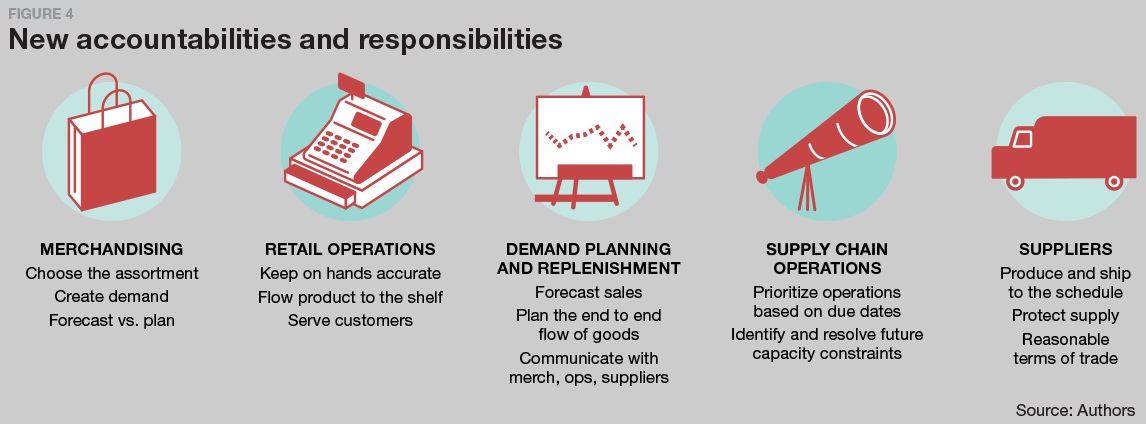

A key aspect of the change was the shift in thinking - or the mental model - of people in a number of core departments within the company.

What emerged was that people within each department would focus on things where they could leverage their skills.

This included improving the customer experience and collaborating with colleagues from other teams when required - critically, as it turned out, only by exception.

The shift is depicted in figure 4 in terms of people’s new accountabilities and responsibilities.

In terms of bottom-line results, the implementation delivered the following significant benefits.

- Achieved the highest store in-stock levels in company history - from 92% to 98% daily across all items in all store locations (including items on promotion).

- The significant year-over-year increase in sales, same-store sales, and profits after the first full year implemented, directly caused by an increase in product in-stocks.

- Improved both in-store and DC inventory performance by more than 10 basis points respectively at the same time that in-stock was increasing.

- Helped reduce in-store labor costs by close to half a percentage point year-over-year by flowing more products directly to the shelf.

- Improved supplier collaboration and performance by sharing accurate, up-to-date supplier schedules - projections of planned purchase orders.

The new process digitally connects the consumer to the supply chain, providing the company the capabilities to implement a new strategic direction for any-channel fulfillment. Rather than supplying online demand from a central warehouse, PAL is leveraging its new capabilities to deliver online demand from a number of strategically located stores across Canada, drastically reducing their fulfillment and last-mile costs and cycle times to better serve online customers. The new planning and inventory flow model is depicted in figure 5.

The new supply chain model is agile, flexible, and consumer-driven - regardless of the consumer fulfillment model - and recalibrates the entire supply chain daily, based on what is and isn’t selling. The process facilitates the ability to profitably plan for and deliver to the Anywhere Shelf - the reality that today consumers can browse and purchase merchandise from anywhere, delivered to anywhere.

The design and implementation of the new supply chain planning model resulted in a significant change to established business processes and their underlying thinking and paradigms that had been ingrained over decades. The project team had, in reality, influenced and helped change the thinking and behaviors of hundreds of people, across multiple organizations.

HOW DID THEY DO THAT?

Catalyzing Change

People-focused. Given the magnitude of the change, the project team understood that the implementation effort would need to be laser-focused on people - helping them change and make the journey. Although the change was enabled and supported by new planning technology, as many in supply chain management can attest, people need to change their thinking in order to maximize the value and utility of the solution and the process it enables.

The team would use an implementation approach that was based on thinking from the Proven Path, made famous and successful by the Oliver Wight Group, and tailored to Princess Auto based on a handful of successful retail implementations. A critical tenant of the approach is the need for company-wide education about the new ways of working.

Education is not the same as training and the two are often conflated. Education and the approach the team undertook would be used to teach the organization the basic process and principles behind it - what was different, why it would work, and why it was better. No software was used in this effort - rather a series of educational sessions with simple examples to highlight various scenarios - designed to engage discussion, ask and encourage questions and spark dialogue.

Education and understanding, it turns out, are not enough to help people make the change. The project team also used a number of other mechanisms to help people make the journey and, in the process, help them change their minds and work habits. As it turns out, the team was employing a number of principles of change that have just recently been articulated in a new, refreshing and valuable framework about change.

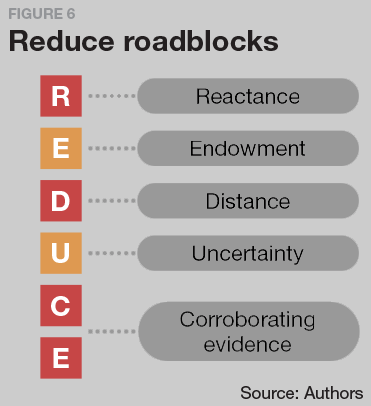

One of the tools utilized by the PAL team was “The Catalyst,” the latest book from Jonah Berger, a marketing professor at the University of Pennsylvania’s Wharton School of Business, and the author of two highly acclaimed books, “Contagious” and “Invisible Influence.” The refreshing aspect of Berger’s approach is his assertion - and supporting examples - that in order for people to change their minds, the barriers to change must be reduced. His approach is nicely articulated in the aptly named acronym “REDUCE” (see figure 6).

Reactance. When pushed, people usually push back.

Just like a boxer has intuitive defensive skills to defend against a punch, people have an innate anti-persuasion system.

A radar that kicks in when they feel like someone is trying to convince them. To lower this barrier, catalysts encourage people to persuade themselves.

Seth Godin, one of the world’s leading marketing experts - and author of the classic book, “Purple Cow” - outlined this concept beautifully: “People don’t believe what you tell them.

They sometimes believe what their friends tell them. They often believe what you show them. But they always believe what they tell themselves.”

At its core, the concept of reactance and the entire change approach the team used was grounded in “questions.”

Rather than tell, the team would ask. And by asking, from a position of attempting to understand, it spurred more questions from everyone, especially the people who had to change.

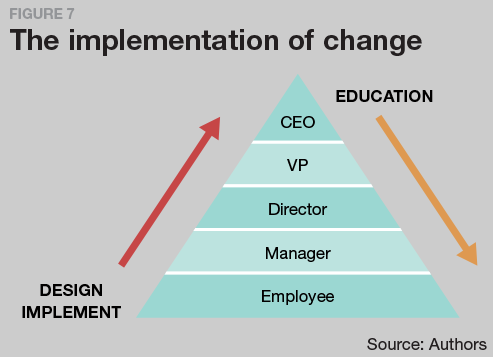

The project team and its executive sponsor would use a simple framework to shape how the change would be implemented and instilled (see figure 7).

The detailed design of how the new process and operating model would work would be the core accountability of the project team and they would work closely with their peers and people in the organization that would execute the process once people understood and agreed.

To achieve this, the organization would need to change its collective mental model about supply chain planning and product flow.

For this to happen, the team built and delivered an education program designed to disseminate information and solicit and demonstrate a commitment to the change. The education started with the PAL CEO and cascaded to all employees and team members.

Starting the education program at the CEO level was important. The goal of the education program was to not only disseminate knowledge but also, importantly, to build commitment and ownership because everyone realized that a change of this magnitude needed to be sponsored and driven by the executive team with an executive-level of commitment.

Questions were at the heart of the education program. The team had built and recorded an educational webinar that explained the new process design and demonstrated it using a series of examples, including the fundamental principles of the process. The cascade model worked like this: The CEO would take the online course and then request that his direct reports (all SVP’s) do the same. Once complete, the CEO would then lead a session (supported by the design team) with his direct reports, where a series of questions would be asked and discussed - ensuring not only a healthy dialogue ensued, but also, importantly, new questions would emerge that would be answered and potentially added to the list.

At the end of the session, the team would revise the list of questions and the CEO would outline the expectation of his direct reports; each SVP would be responsible for ensuring their direct reports took the online course and, more importantly, attended a facilitated session (led by each SVP) where the questions would be discussed and answers and opinions documented. The cascade would continue down the company hierarchy until everyone had reviewed the education and attended a principles-and-questions-based session to help people convince themselves and build commitment to the change.

The cascade model of education helped to increase understanding of the change and was a key mechanism to reducing reactance because the foundation of the approach was based on questions – some were asked but most were surfaced and answered by peers, helping a person persuade themselves. Instead of telling, people were asking.

Endowment. Everyone has heard the old saying, “if it ain’t broke, don’t fix it.” People are married to what they’re already doing. And unless what they’re doing is horrible, generally they don’t want to switch. To ease the effects of endowment, or people’s love of the status quo, catalysts highlight how inaction can be very costly.

Early on, the executive and project teams determined the cost of inaction. While the supply chain was performing at a level consistent with the industry and major competitors, the teams looked to world-class retailers like Amazon to help determine the cost of complacency.

As an example, they correctly determined that, over time, retailers like PAL would be expected to be in-stock at exceptionally high levels - approaching 99% - for every item, every day, in every store. Based on the current performance they concluded that reaching these aspirational levels would deliver tens of millions in additional annual revenue and resulting margins, as well as improving their customer satisfaction and journeys.

In addition, they also highlighted and correctly determined the potential bottom-line impact that the shift in consumer behaviors - to a more digital mindset and shopping preference - could have on overall company and supply chain performance. Amazon and others were driving a relentless and ongoing improvement in deliveries and cycle times and the executive and project team understood this and assessed that “waiting for the future” just wouldn’t cut it.

As a result, the organization understood - both financially and potential improved capabilities - the cost of inaction was huge and could not be ignored.

Distance. People have an innate anti-persuasion system, but even when we just provide information, sometimes it backfires. Why? Another barrier is the distance, or how far the change is, mentally. If new information is within people’s zone of acceptance, they’re willing to listen. But if it is too far away, in the region of rejection, everything flips. Communication is ignored or, even worse, increases opposition. To help ease this barrier, catalysts often ask, initially, for less, instead of pushing for more.

The project team embraced this principle, which was inherent in the overall plan. People would be educated first about the concepts and principles of the change. If that took longer than expected, which it did, the team slowed the pace, allowing additional education sessions, always cognizant of the questions being asked and the understanding and comfort people were displaying regarding the change.

In addition to pace, another key tactic used to help reduce distance was that the project team held numerous “lunch and learn sessions” (though sometimes they were later in the day and were “beer and pizza” sessions, the idea is the same) designed to help people better understand the new world, in their terms and language. The team did not ask people to eat the entire elephant, but rather small, digestible bite-sized chunks to help them reduce the distance of the larger change.

A wonderful example of this was highlighted when the project team helped a number of the category management members understand that the new process would forecast sales by item/store based only on that item/store’s sales history. During an early “lunch and learn” the team demonstrated, for the first time, a particular product and its sales history and resulting forecast for a product from the Edmonton, Alberta store. Upon seeing this, the initial reaction from the category leader was emphatic: “That’s wrong. There is no way that product could sell like that in Edmonton.”

Thankfully, the project team and executive sponsor listened and then said: “You may be right because you know the product better than us. Can you ask your team members to also think about it?” The category leader left the session and did what was requested.

There had been no push back. No confrontation. What was remarkable is that during one of the subsequent sessions he asked if the project team could demonstrate that product again and the forecast for the Edmonton store. He then outlined to the room, including his peers, that he’d asked his team and did some thinking and they all concluded that indeed that product in Edmonton not only could but did sell like that.

Instead of focusing on the entire supply chain, the understanding of why the process needed to create forecasts based on each product's sales history for each store had been confirmed. An important and small change in terms of distance from the current state to the eventual future state. As he outlined to his peers, and they agreed, they had never looked or thought about things like this. He had convinced himself by asking questions and reducing the distance of understanding.

Uncertainty. Almost always, change involves uncertainty. In this case, would the new process be as good as hoped? It’s hard to know this for sure, and this uncertainty often makes people resistant to change. To overcome this, catalysts make things easier to try.

To make things easier for people, the implementation would use ideas and mechanisms from the discipline of design thinking – using, often, the concept of a prototype.

To allow for trial-ability, the team relied heavily on what they would describe as a “process prototype.” A process prototype is much like a product prototype - essentially a “day in the life” of the new processes, executed with real data by the future planners and users

so that they understand, see and feel the new process.

It provides users a safe environment to experience the new process after they have been educated and, critically, provides the implementation team with feedback and input on the process and solution. They can share what they like and what they don’t like, along with ideas for improvement.

As an example, one of the process prototypes focused on the common retail planning scenario of product discontinuation – how to exit a product from the assortment with minimal product carryover and without the typical large discounts as a product is trying to be sold off. The team had designed a process and resulting workflows that provided much better visibility for the category teams to make improved and more profitable decisions.

They engaged the actual users in the prototype - allowing the end-users to perform the process in a safe environment but, critically, with real and up-to-date data that the business teams would recognize and resonate with. The prototype went poorly in terms of keeping the process consistent with what had been designed on paper.

However, as is the case with prototypes, the end-users surfaced some ideas and thinking that were marked improvements on the current design and the project team went back to iterate the design. As it turned out, a member of the design team, sparked by the idea that arose during the prototype, discovered little known or used functionality in the technology solution. The designs were altered and a new and improved prototype was executed with the same business teams. The result was almost universal acceptance of the new design, which is used today to manage this key business scenario.

The prototype not only surfaced a better way but also something much more important in terms of reducing barriers to change. It allowed business users the opportunity to test or try the new process and, importantly, when they asked why the process seemed like too much work, they were thrilled when the project team returned with an answer to their question. From their view, the design team had listened.

The implementation team facilitated a series of small, process prototypes to iterate and improve the process, gaining buy-in from the planners and users, including store personnel, operations, merchants, and suppliers. As users become more comfortable, they would communicate to their peers about how the new process would likely work. By doing so, they were slowly “telling themselves” and their peers that the new approach would work.

The prototype approach also provided the implementation team the opportunity to see how people ingrained the education they had been previously provided - what worked well, any struggles they encountered, and where the implementation team would need to provide refresher education, training, and coaching.

A process prototype approach generally takes a little longer to implement a new process and solution, but, importantly, it makes the change smoother and the overall implementation faster and more sustainable. That helps to ensure that the principles of the new process are ingrained and that business results can be sustained. In hindsight, the PAL project team concluded that the process prototypes allowed people to trial the new process, and ultimately help them make the shift in thinking.

Corroborating evidence. Sometimes no matter how good is the design or idea, or no matter how knowledgeable or assured the people who are implementing it, it is not enough. Some things and some changes need more proof. More evidence to help people overcome the translation problem and become more comfortable with the change. To overcome this barrier, catalysts find reinforcement through corroborating evidence.

The project team at Princess Auto embarked on changing and integrating the entire retail supply chain - from consumer/store to supplier - for all products, all stores, and all suppliers. The executive and project teams understood that, according to current literature, this had rarely been accomplished to scale in retail.

However, the teams did understand that components and pieces of this integrated planning process had been implemented and well established - both of which had adhered to the concepts and principles of the flow casting business process, the foundation for which the change was built on. Two of Canada’s largest and most successful retailers provided a number of examples of the components of the change and the effort to instill them.

For instance, Canadian Tire Corporation provided significant evidence of the positive impact on suppliers and the supply chain using the concepts of supplier scheduling. In addition, the project team had intimate and detailed knowledge of the lessons learned as Loblaw Companies Limited had embarked on a similar change a number of years before. When required, these trump cards were played to help people understand they were not charting completely undiscovered waters - rather we would be putting all of the pieces and learnings together, connecting the retail supply chain from consumer to factory, for all products, stores, and suppliers.

Changing Your Framework

Change is hard, but also necessary. The transformation in supply chain planning at Princess Auto was a significant and very successful effort, providing the teams some important learnings. The most important is that change is about people and people are emotional. In business, remember Joe Jackman’s pearl of wisdom: “Change is a human endeavor with business consequences.”

If Joe and others are right - and we concur from experience - then change is not only about facts, figures, and new ideas and thinking. It’s also about helping people make and instill the change – think differently and alter their mental models. People, of course, resist change for many of the reasons outlined above. To help them, barriers to change need to be reduced or eliminated.

The transformation of planning processes at Princess Auto completely changed how product flows were planned, from consumer to factory. In the process, hundreds of people had to change their day-to-day activities and instill new ways of working.

A good design was important. Education helped a lot. So too did ongoing dialogue, including surfacing and asking lots of questions. In hindsight, however, reducing the barriers or resistance to change was a critical, and often overlooked, the element of making it happen.

About the Authors

Mike Doherty is a partner with Demand Clarity Inc. He is the co-author of “A digitally connected, consumer-driven supply chain,” which appeared in the May/June 2019 issue of Supply Chain Management Review, and co-author of “Flowcasting the Retail Supply Chain.” He can be reached at [email protected]. Kimberley Kirton is vice president, Supply Chain Operations at Princess Auto Ltd. She can be reached at [email protected].

Related Resources

Who Owns Inventory?

Who owns inventory? stop the blame game, it’s a common question, but the wrong question to ask, this white paper explains why and what you should be asking. Download Now!

4 Ways Analytics can Augment Your Inventory Planning

While inventory management is complex, gathering, prepping, blending, analyzing, and auditing your data shouldn’t be. Download Now!

Education as a Strategic Advantage

This white paper details Robert Hirschey’s experience in working with companies to develop education as a strategic advantage, Hirschey has worked as an executive at both the operating and strategic levels. Download Now!

More Resources on Inventory Management

Related Article: Never Ask “Who Owns The Inventory?” Again - It’s The Wrong Question to Ask

Article Topics

Alteryx News & Resources

Beyond COVID-19: How to Leverage AI and Analytics to Minimize “Supply Chain Disruption” Prepare Your Supply Chain for Uncertainty How to Change Your Supply Chain Inventory Planning Process 4 Ways Analytics can Augment Your Inventory Planning From COVID to Coca-Cola: Analyzing Distribution Models Create Predictive Models in Seconds for Faster and Better Forecasting Modern-Day Analytic Automation More AlteryxLatest in Supply Chain

How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency More Supply Chain