Honing S&OP Through the Art of Questioning

The simple process of questioning details is one of the simplest, most productive S&OP techniques.

Early in my career, I was given some arm-around-the shoulder advice by a mentor.

He said, simply, “Question everything.” When I asked what he meant, he smiled and responded, “You’re learning.”

He urged me to ask questions of people - not to interrogate them to the point of being obnoxious, but to never be afraid to ask just for curiosity’s sake.

He told me to question in order to validate what’s being said; to learn about others, what they do, and how my role affects theirs; and to gain wisdom everywhere. His words stuck with me.

This advice is, of course, steeped in the Socratic tradition dating back to ancient Greece. It involves disciplined questioning that is designed to advance learning; deepen knowledge; and foster a sense of engaged, active participation, particularly with regard to exploring complex topics and then revealing assumptions or biases.

I observed my mentor as he habitually modeled this art of questioning. He used his interpersonal prowess in business settings, asking question after question to probe issues and get to the root cause of problems.

He would pull apart the most complex subjects, revealing answers that weren’t always obvious, and increase a group’s collective knowledge and competency.

Read: The Value of a Supply Chain Executive Education

He would ask others about their own work and lives, and they would oblige him with information because, let's face it, most of us like to talk about ourselves. As a result, he got to know people better and quickly and easily forged genuine personal relationships.

This skill also helped him gain greater knowledge about organizations, competitors, clients, and prospects. He was successful; well-liked; and, interestingly, respected for his opinion, despite the fact that he rarely offered any inkling of his own position on any subject.

Actively challenging

Fast-forward to my early years as a supply chain management consultant. Just as my mentor had encouraged me to do, I began inviting my clients to actively challenge each step of the sales and operations planning (S&OP) process.

I knew from personal experience that the concept of questioning everything was well suited to S&OP, yet it was nevertheless a risk to presume that all clients would equally welcome the notion - especially considering the vagaries of organizational dynamics from one company to another.

The very expression “actively challenge” implies a certain boldness and can be off-putting to some, as rapid-fire questions sometimes suggest ill intent for political gain.

Therefore, it is best to establish an agreed-upon process for actively challenging prior to beginning. As S&OP leaders, it is our job to model the behavior so all participants gain a comfort level and to ensure long-term adoption of the practice.

It’s also important to keep in mind that the process is not intended as a means to bully or as some intellectual gauntlet to be run. Challenges should never be mean-spirited devil’s advocacy but, instead, a way to put any plan through its paces.

That all having been said, questioning is so important to S&OP. I described to my clients the value that can be derived by asking questions, which includes the following:

- Questioning refines assumptions inherent in a plan, helping reduce variance.

- Encouraging one person to ask questions can open the floodgates for others to join the discussion, creating a deeper, richer understanding of key operations and business subtleties while fostering more collective ownership of the plan itself.

- Establishing this dynamic helps ensure participants are well prepared for planning meetings, have done their homework, and have thought through questions they might be asked or need to ask. Because S&OP is predicated on detailed analysis, this effect is an important win.

- Probing reveals issues, problems, and hidden agendas. If a plan is unsupported by facts, there is usually a reason, which this process helps identify. It also gradually eliminates unstated biases.

- Open, collaborative questioning helps identify key facts that are missing or being overlooked in the process, highlighting areas ripe with opportunity for improvement.

- Actively challenging anything and everything moves S&OP plans closer to reality-based scenarios and thus farther from the influences of factors such as optimism, pessimism, opinion, ignorance, or (in some cases) downright incompetence. When assumptions are fact-based, plans better reflect reality—for better or worse—and the potential opportunities to improve operational efficiency, customer service, profitability, and much more.

If one of my clients’ forecasts was based on point-of-sale data, I would question if it was accurate and had full coverage. When working on a supply plan, I questioned all supply-side attributes and rules of thumb, which are notoriously incorrect.

I would ask numerous, different questions, trying to understand the certainty of a client’s capacity plan; what the known demonstrated performance of the production line might be; or even something as simple as, “Do you have any shutdowns planned for the future?” No matter how trivial they seemed, all of my inquiries had a similar purpose: to get a handle on or improve the quality of the plan.

I used the same technique to help evaluate new product forecasts, which often have twice the error level of base stock keeping units (SKUs). I would ask clients, “What analogs were used to devise the new product forecast, and how were they selected?” or, “When will the media kick in?” and, “What happens to our capacity picture if we hit the upside in the plan?”

Every product level, family, grouping, sub-brand, category, capacity group, and item on the innovation funnel or SKU list presents an opportunity to ask a question. Sometimes they may be quasi-technical in nature:

- What does the statistical forecast tell us?

- What is the level (average) of this demand?

- Does it have seasonality?

Other times, questions may be about the consumer, the cohort, the competition, or the impact of a new creative campaign. No matter the subject, when supply chain management professionals recognize all operational avenues as fair game for analysis, constructive probing ensures that the plan is well vetted; based on real data; and will help discern the subtle, yet essential, difference between facts and opinions.

Of course, not all questioning related to S&OP should be tactical. When appropriate, questions can and should have a strategic focus:

- When are we going to exhaust capacity at current shipment trends?

- Do we expect share growth to continue?

- What is the marketing strategy behind the product portfolio in this segment?

- What is the annual estimated sales value of items in the innovation funnel? Such queries help refine the long-term vision attached to strategic plans.

The power of a question

I have been coaching supply chain management professionals on actively challenging for almost 20 years. The simple process of questioning the details embedded within each plan is one of the simplest, most productive S&OP techniques. Take some time each day to question yourself, your processes, and your colleagues. You will be pleasantly surprised by the results.

Encouraging one person to ask questions can open the floodgates for others to join the discussion.

Patrick Bower is senior director of global supply chain planning and customer service for Combe. He is responsible for the company’s sales and operations planning process, order management, and third-party logistics management. Bower may be contacted at [email protected].

Related Article: Best Approaches to Survive Supply Chain Complexity

Related White Paper

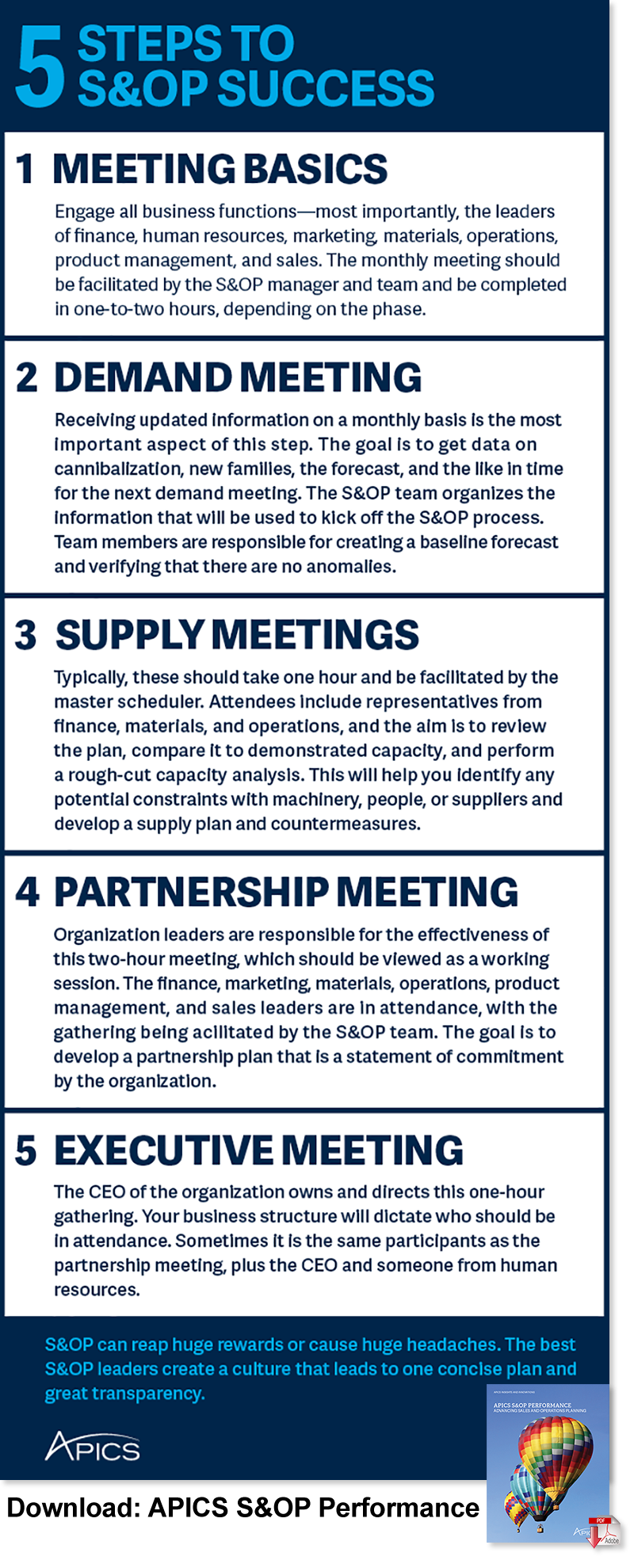

S&OP Performance: Advancing Sales and Operations Planning

An effective sales and operations planning (S&OP) process guides business decisions, provides key problem solving strategies, gives executives greater control over the enterprise and drives overall business success. Download Now!

Article Topics

ASCM News & Resources

Supply Chain Stability Index sees ‘Tremendous Improvement’ in 2023 Supply Chain Stability Index: “Tremendous Improvement” in 2023 The Right Approach for Supply Chain Education The reBound Podcast: Innovation in the 3PL supply chain Supply Chain’s Top Trends for 2024 Require Talent Investment for Success Resilience Certificate Now Available from ASCM ASCM conference highlights importance of geopolitics in the supply chain More ASCMLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain