GreyOrange Co-Founder Discusses Trends in Micro-Fulfillment and Mobile Robot Fleet Management

GreyOrange also weighs in on multi-tenant environments, software accounting for humans in the loop, and interoperability efforts.

Most adoption of mobile robots has been in warehouses, but there are relatively few mixed fleets so far. GreyOrange Inc. said its GreyMatter platform is hardware-agnostic and can orchestrate multiple robots in a variety of facility configurations.

The Roswell, Ga.-based company also said its hardware and software can meet the performance levels that supply chains require, as discussed in recent Gartner Inc. research.

In a session at ProMat 2023, GreyOrange strove to “demystify” automation for fulfillment. In addition, the company is among those working with third-party logistics provider (3PL) Wagner Logistics on rethinking warehouse robotics.

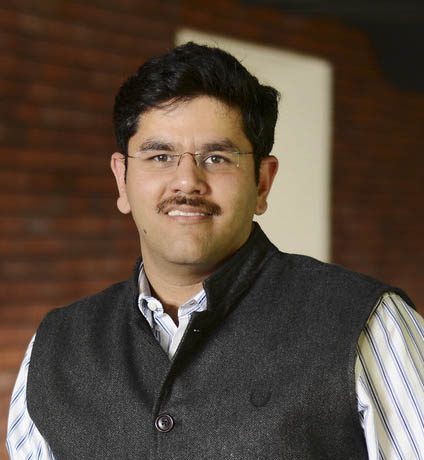

Samay Kohli, co-founder and past CEO of GreyOrange, spoke with Robotics 24/7 about micro-fulfillment centers, multi-tenant spaces, and robotics.

Fulfillment evolves into new spaces

What do you think about the prospect of multi-use retail stores that include fulfillment space?

Kohli: It's a relatively new concept, and not many of our customers have gone to it yet. But since we're omnichannel and muti-brand, we're ready for it.

For instance, H&M uses us for six different brands within the same building for existing inventory. Before GreyOrange, the brands coexisted, but their online and retail sides were handled separately. Now, it's all in the same mix of inventory.

The channel gets decided when an item goes outbound, packed in a box or an individual carton. We've seen this need for nuance in the industry for a long time.

For brands to effectively adopt automation, they need a common ERP [enterprise resource planning system] and operations. We developed GreyMatter around that need for orchestration.

How does that compare with most retail today?

Kohli: The idea of shared retail space is becoming more common today—see Taco Bell and Pizza Hut. In the case of Amazon and Kohl's, it's not on the sales side but the returns side.

Why would Kohl's allow Amazon users to return items to its stores? Returns helped its foot traffic for buying.

How have this evolution and micro-fulfillment affected warehouse processes?

Kohli: Robotics and automation can make half their problems go away. As human beings, we think of different brands, but the challenges for warehouse managers are how to manage resources and getting personnel trained on picking and packing.

The analogy here is that robots are like the cloud era. You could have two brands use the same servers to do different things, and they didn't need to set up individual servers.

If you didn't have automated servers, humans would have a tough time allocating memory dynamically. With automation, you can set rules, and it's the same for robots in a warehouse as for data in the cloud.

A retailer doesn't need to know which brand is on a shelf; it just needs to find it at the packing table. Robotic and manual fulfillment operations can be dedicated to the entire value stream.

AI and interoperability

What's the role of artificial intelligence in automating processes and working with employees in multipurpose fulfillment centers?

Kohli: GreyMatter is built with the understanding that humans and robots are going to coexist. With large-scale systems, we take the robot as not as perfectly reliable as a big machine would be.

With humans in the loop, it can be over 95% accurate, and GreyMatter takes a feedback loop 100 times a second.

Human pick rates change, depending on the shape and size of the goods they're handing and the individual pickers. You can get more robots to increase people's pick rates and allocate fewer robots for slower pickers.

The second challenge is differences in reliability. The only way to handle this is to have a real-time system for multi-robot orchestration like GreyMatter. The industry has been stuck because it depended on so many manual processes.

How does Grey Matter compare with interoperability standards efforts?

Kohli: We're watching the MassRobotics, OpenRMF, and other efforts. Users have to pick the right systems for their applications.

Our big advantage is that we're already running practically, while others are still writing their standards. We're following the Apple-style approach of customer-end delivery. GreyOrange customers are already running sites with multiple robots.

We're also a contributor to VDA 5050. Our intent is not to create a secret “black-box” solution—we're on the practical side. One part of our open API follows VDA 5050 and is not proprietary.

If customers have a problem and need to buy a solution now, we're already running it and at scale.

Packing and partners

How much does GreyOrange work with packaging systems?

Kohli: We're pretty tightly integrated with a number of packaging automation companies such as Packsize. We're always on the lookout for any robot-based packaging systems, because conventional carton and box handling can be pretty rigid.

One client is going live with the largest version of GreyMatter in which the user touches a package once—to remove it from an AMR [autonomous mobile robot]. Nobody else touches it before it leaves. Amazon has two touches—removal and packing.

If GreyMatter is robot-agnostic, how does GreyOrange work with different vendors?

Kohli: We partner with some third-party companies. Some robot companies do consider them competitors.

We have our fair share of partners—Fetch/Zebra, HAI, Quicktron, and Tompkins—for early adopters that are starting to come on board. We hope to get more.

We work with multiple players, and there's no information sharing. Some people understand inventory management and warehouse management systems [WMS]. Others want to build it themselves, and there's a maturity curve.

It's less about robots and more about how to manage inventory, audit cycles, and unit discrepancies. To run at 99.97% uptime, there's a lot to do, and if you have a WES [warehouse execution system] that stops receiving orders for a couple of seconds, it shouldn't break the bank.

GreyOrange strives to exceed expectations

What are your customers looking for?

Kohli: People looking for adoption may sell directly to CEOs or to other systems integrators that usually run more pilots. GreyOrange may not claim to match that value, but we run more actual systems.

We sold 3,000 intralogistics robots to one company last year, and it was the first one that had used more than 50 of our robots at one site. In nine months, that customer went from 15 robots on average per site to 79, and it hardly has any forklifts anymore.

Lots of other warehouses buy three, four, or 10 AMRs at a time, but not many have moved up the curve of maturation that quickly.

What are your expectations for GreyOrange this year?

Kohli: One of the areas of biggest change is multi-robot deployments. We've gone from two customers using robots from two manufacturers in their warehouses to almost 30% of our customers with multi-robot use cases in 2022.

GreyMatter is helping customers on their journeys toward multiple robots. With our API, we want to accelerate them.

Article Topics

GreyOrange News & Resources

Autonomous mobile robots (AMRs) on a mission GreyOrange demonstrates results-driven robotics 4 Tech Directions to Shape Distribution Center Performance GreyOrange closes on $135 million in growth financing GreyOrange and Hai Robotics dynamic partnership addresses automated robotic fulfillment Is an automatic guided vehicle (AGV) in your future? Four tech directions to shape distribution center (DC) performance More GreyOrangeLatest in Supply Chain

U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating More Supply ChainAbout the Author