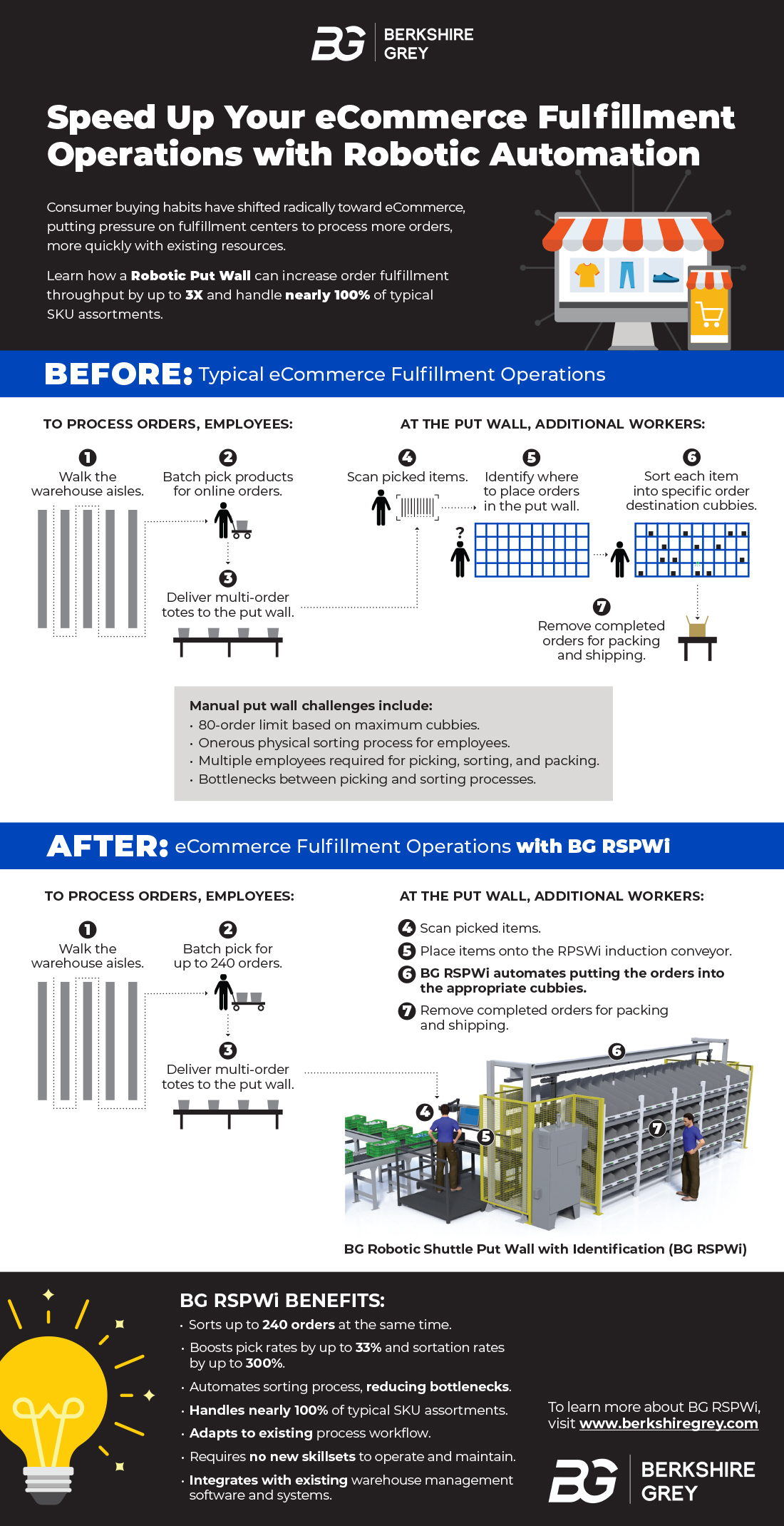

Four Reasons to Rethink Your Ecommerce Fulfillment Operations Using a Robotic Shuttle Put Wall

The surge in ecommerce is putting a strain on order fulfillment and exacerbating labor challenges, but a robotic put wall could be the key to increasing productivity with minimal disruption to existing warehouse operations.

Keep Up With Sustained Demand

Shoppers turned online when the pandemic shuttered physical stores. As ecommerce sales rose, so did consumer expectations.

Shoppers today are accustomed to rapid order turnaround and multiple deliveries and pickup options, but not every retailer is proving they can keep up with the sustained demand.

For many traditional retailers, ecommerce companies, and 3PLs, the surge in ecommerce has put a strain on labor and exposed bottlenecks in order fulfillment processes.

Here are four reasons to rethink your ecommerce fulfillment operations to stay competitive in the new retail reality.

1. Ecommerce Keeps Climbing

Consumers spent $861 billion online with U.S. merchants in 2020, an increase of 44% compared to 2019, according to data from Digital Commerce 360. That’s the highest annual U.S. ecommerce growth in two decades, the research firm estimates.

And there’s no sign of online shopping leveling off: U.S. retail ecommerce sales are expected to climb another 18% in 2021, according to Insider Intelligence.

2. Ecommerce Fulfillment is Labor-Intensive, and Labor is Scarce

The online sales explosion is great for revenue, but not necessarily for profitability. Getting online orders out the door requires a lot of labor, particularly because shoppers often buy just one item online at a time. Picking, sorting, and packing are largely manual processes compared to traditional retail distribution operations.

Labor availability is a pressing problem. The Bureau of Labor Statistics reported 10.9 million job openings at the end of July, and the retail industry is feeling the pressure. In the past, retailers have addressed upticks in ecommerce volume by hiring more labor.

But now, faced with an order surge of epic proportions, retailers are struggling to find enough people to hire. Retention, too, remains a problem in high-turnover warehouse roles.

3. Increase Fulfillment Throughput Without Disrupting Operations

Pre-pandemic, it was typical for distribution centers to be set up with the 80/20 rule: 80% of the systems and space served store replenishment processes, and 20% handled ecommerce order fulfillment.

These days, the split might be closer to 50/50, and most warehouses weren’t designed for that kind of ecommerce volume. The result is a critical bottleneck at the picking and sorting stages of order fulfillment. Manual put walls are widely used to support ecommerce order fulfillment, but they were not designed to process enough orders to keep up with demand today or in the future.

While many companies might recognize the need to introduce automation into their processes now, the idea of slowing or stopping operations is a deal-breaker. But robotic put walls available today feature modular designs that won’t disrupt existing processes.

4. Selective Automation Can Boost Employee Productivity

Robotic put walls are designed to speed up order processing and optimize labor. When a put-wall worker takes picked products and loads them into a robotic shuttle for scanning and delivery to the appropriate cubbies, that frees the worker from the time-consuming process of figuring out which order a product is destined for, then walking to a cubby for sorting. That makes the sorting labor much more efficient: With a robotic put wall, workers can sort orders up to three times faster than with manual-only processes.

Plus, the benefits aren’t limited to sorting efficiency. There are upstream gains as well. Automated put walls can process more orders at once, which means manual pickers can be picking products for more orders as they traverse the warehouse aisles. The ability to pick for more open orders can yield a more than 30% improvement in upstream picking productivity.

Adding an automated put wall doesn’t require rearchitecting operations. Retailers can maintain their existing processes while eliminating a key bottleneck with a Robotic Shuttle Put Wall (RSPW). The modular design lets retailers plug new technology into the most pressing trouble spots - without extensive construction - and expand deployments at their own pace.

Retailers, ecommerce companies, and 3PLs can fulfill more ecommerce orders with the people and the buildings that they have today and be confident that an RSPW investment will be compatible with future robotics deployments.

Related Resources

Intelligent Enterprise Robotics for Ecommerce

In this ecommerce solution guide, we take a deep dive into how to improve sortation throughput by up to 3X without additional labor, additionally, we provide 3 reasons retailers need robotic product sortation in fulfillment warehouses. Download Now!

3 Myths of Robotic Picking

In this ebook, we detail how scalable robotic systems can help supply chain fulfillment centers and debunk the three most common myths. Download Now!

3 Ways Robotic Package Sortation Reduces Shipping Costs

Improve labor utilization, save on shipping costs, and accelerate delivery speeds by automating package sortation. Download Now!

Retail Store Replenishment Success Story

This case study shows how Robotic Product Sortation Systems were implemented to fulfill store replenishment orders for a fortune 5 retailer and provides 3 reasons retailers need robotic product sortation in fulfillment warehouses. Download Now!

More Resources from Berkshire Grey

Related Article: Solving the $120 Billion eCommerce Returns Problem with AI Robotic Automation

Article Topics

Berkshire Grey News & Resources

Automation is Filling the Labor Gap Ahead of Peak Season ProMat 2023 – Automation at a crossroad Berkshire Grey enters merger agreement with SoftBank Group for go-private transaction Berkshire Grey and Locus Robotics partner to achieve cross-platform robotic automation Amplify your order picking and AS/RS systems with robotic automation Amplify your order picking and ASRS systems with robotic automation Deploy robotic solutions with RaaS to enable worry-free and flexible supply chains More Berkshire GreyLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology