FORTE provide BDF Beiersdorf distribution operations increased capacity and reduced labor costs

Beiersdorf, one of the fastest-growing cosmetics manufacturers in the world, needed a flexible North American distribution strategy to keep up with the firm demand for its Nivea, Eucerin and La Prairie skin care products.

An acquisition and new customer shipping requirements provided a fresh opportunity to develop a world-class distribution center that would deliver the flawless performance needed to support their radiant growth for years.

With the help of FORTE, Beiersdorf consolidated three distribution centers into a single highly automated facility, enabling them to improve picking and shipping accuracy while doubling capacity and reducing operating costs 15%.

The Challenge

Beiersdorf, a leading international manufacturer of branded consumer products for skin and beauty care, needed to achieve labor cost efficiencies in its North American distribution operations. Given a recent acquisition, Beiersdorf also wanted to develop a consolidated, world-class warehouse design to minimize costs while ensuring optimal levels of picking and shipping accuracy.

The Solution

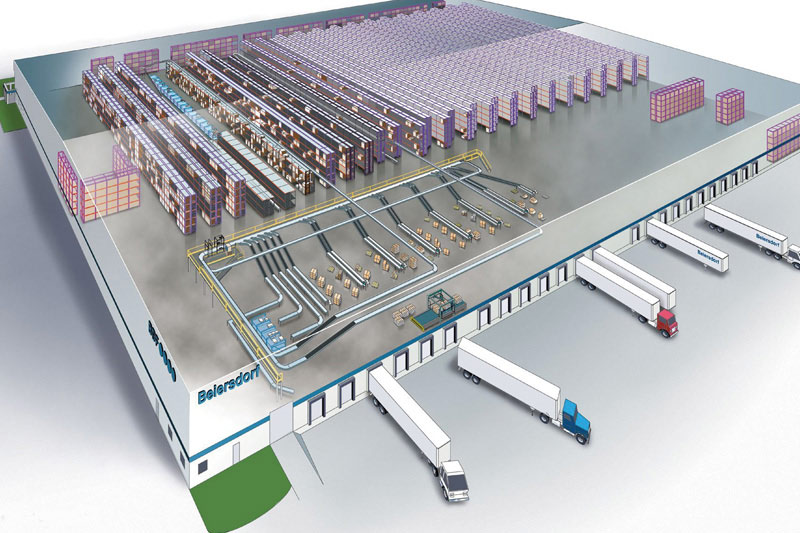

FORTE designed and implemented a new 250,000 sq. ft. distribution center in West Chester, Ohio, recommending a smaller, expandable building rather than the larger facility Beiersdorf had originally considered. Utilizing FORTE’s Automation Director™ warehouse control system (WCS) software, the warehouse management system (WMS) was integrated with the new material handling system.

Multiple changes were designed and implemented as business requirements evolved, e.g., a large customer requiring smaller cases and more frequent shipments. FORTE also altered mechanical material handling equipment to accommodate new material to be handled, such as converting split-case pick modules to full-case pick modules when split was no longer required.

The Result

The new DC increased capacity by 100%, reduced labor costs by 25% and reduced operating expense by 15%, with a calculated ROI of 15%. Order turnaround is performed in less than one hour with greater than 99% accuracy and on-time delivery of greater than 99%.