Envisioning & Planning the Future Warehouse of 2030

The warehouse of the future will be shaped by trends in society, technology, and consumer behavior, this post, along with the Future Perspectives paper, Planning for the Warehouse of the Future, shows you what it could look like.

Envisioning & Planning the Future Warehouse of 2030

Remember what your warehouse was like 12 years ago when e-commerce was still in its infancy and most of us were unfamiliar with the term omnichannel?

It isn’t easy. With the constant influx of information in today’s digital world, it can be hard to remember what we had for lunch yesterday; let alone what was happening in warehouses 12 years ago.

Needless to say, a lot has changed since then.

Now imagine trying to predict what your warehouse will look like 12 years in the future, especially considering that the pace of change continues to accelerate. That may be even more difficult.

Yet, having a vision of where things are going in the future can help you make better decisions in the present.

And, as it turns out, what’s happening in the present, if we analyze it closely enough, can provide powerful clues as to what is coming - even as far as 12 years into the future.

Over the past three months, a team of Swisslog and KUKA specialists did exactly that.

We took a systematic approach to analyze societal and technology trends that are emerging today and projected their influence on the warehouse of 2030.

In terms of trends, here is a sample of what we reviewed:

- Globally, the population is becoming more urban and incomes are rising. In developed countries, the population is aging and the workforce is shrinking while those trends are reversed in developing countries where birth rates are higher.

- There are significant technological developments emerging today that will, in all probability, shape the warehouse of the future. Those include predictive analytics and machine learning, autonomous vehicles and drones, robotics, and 3D printing.

- The changes in consumer behavior we see today can also be extrapolated into the future. These include the growth in omnichannel retail in which consumers move seamlessly across channels and choose what to purchase and how based on their specific circumstances at the time of purchase. They will also continue to demand greater personalization and customization. And, they will have even less tolerance for delivery delays. When they purchase something, regardless of the channel, they will expect to receive it the same day.

So, what does this mean for the warehouse of the future? Here are some of the key takeaways from our analysis:

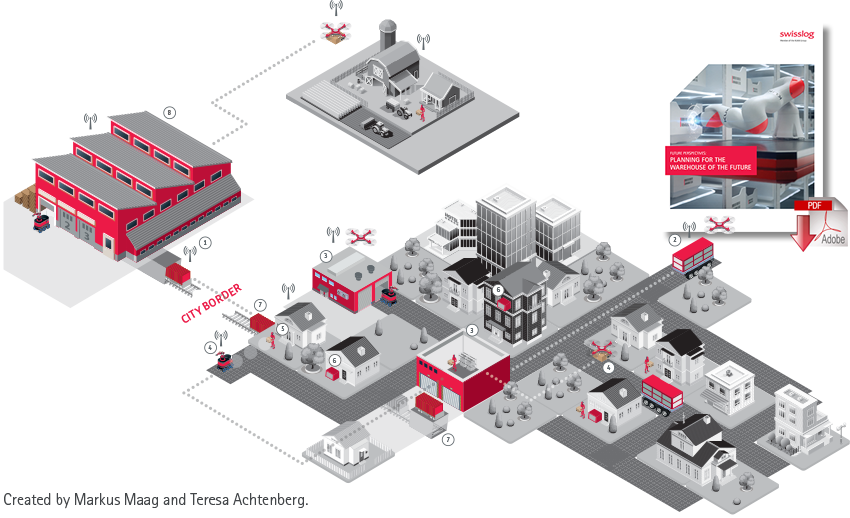

- The warehouse must move closer to the customers it serves. We envision growth in urban distribution centers that stage products close to users within large cities to enable faster delivery and a more seamless omnichannel experience. The obvious challenge to this scenario will be the space limitations and relatively high real estate costs inherent in urban markets. This will dictate compact and efficient warehouses with limited inventories that are optimized using predictive analytics and supplemented with 3D printing.

- The space constraints imposed by urban environments will likely also impose a shared service model in which multiple sellers share space in the same facility with products from these sellers consolidated for delivery similar to how parcel shippers consolidate packages today.

- The urban warehouse must be equipped to produce products as well as store and ship them. With greater customization on the horizon and the continuing maturation of 3D printing technology, the urban distribution center will be well positioned to “print” products on demand and then package and deliver them just as they do products from inventory.

- The urban distribution center must be configured to support same-day delivery or customer pickup through some combination of autonomous vehicles, robotic picking and loading, drones and mobile pickup points.

- Technology will play a significant role in delivering the speed and efficiency required and automating the movement of products from large regional warehouses to the urban distribution centers while enabling faster picking, loading, and delivery of these products.

Sound interesting? I encourage you to read our paper, Planning for the Warehouse of the Future. It provides a more thorough review of trends shaping the future of distribution and a more detailed picture of what the urban distribution center of 2030 will look like and how it will operate.

About the Author

Michiel Veenman | As the head of Swisslog’s Competence Center, Warehouse & Distribution Solutions, Michiel is responsible for the development of some of Swisslog’s next-generation solutions. Michiel has over 20 years of experience in intralogistics with roles varying from consulting, design and project management to market strategy and innovation.

Planning For the Warehouse of the Future

Conceptual view of distribution in the future, showing a large warehouse outside a city supporting multiple urban distribution centers with a variety of transportation options from the central warehouse to the urban DC and from the urban DCs to consumers.

Download the Paper: Planning for the Warehouse of the Future

Article Topics

Swisslog News & Resources

Walmart chooses Swisslog AS/RS and software for third milk processing facility Walmart and Swisslog Expand Partnership with New Texas Facility Swisslog gives live demonstration of ItemPiQ latest evolution Cardinal Health at-Home Solutions automates from shelf to patient Inside Cardinal Health at-Home: Getting the right products out the door at the right time Retail distribution closes in on the customer Automated storage on the move into 2024 More SwisslogLatest in Warehouse|DC

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring More Warehouse|DC