Enhance the Value of Your Supply Chain Supplier Relationships

Developing and executing the right kind of supplier relationship based on the right kind of sourcing business model moves an organization from traditional supplier relationship management to the next generation.

Appropriate Sourcing Business Models Enable Flexibility and Mutual Benefits

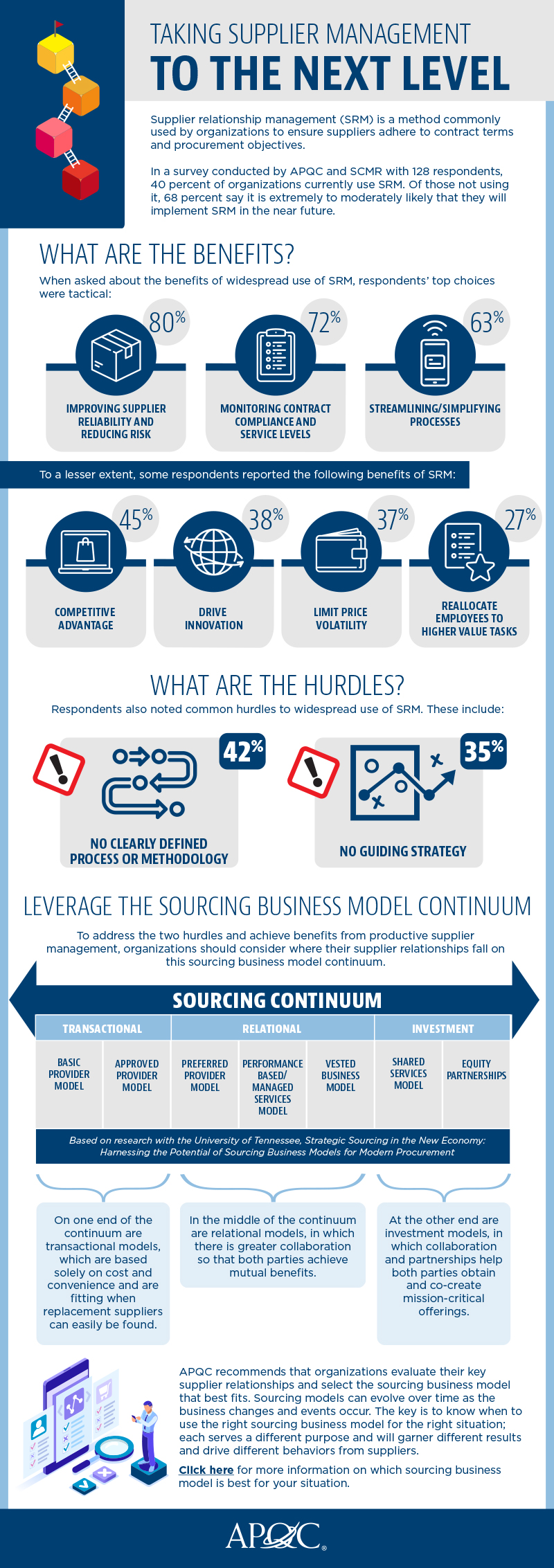

Supplier relationship management, or SRM, is commonly used by organizations to ensure suppliers adhere to established contract terms and performance objectives.

A recent survey conducted by APQC and Supply Chain Management Review (SCMR) revealed that most organizations are familiar with the principles of SRM and that nearly 40% of organizations are using SRM with their suppliers to some degree.

Nearly a quarter of respondents indicate that their organizations do not use SRM but are exploring their use.

Many organizations that do not use SRM intend to implement it in the near future.

Although 31% of survey respondents are not using SRM, when asked about the likelihood that they will implement the approach, 68% of respondents said that it is extremely to moderately likely.

Clearly, organizations consider this way of managing suppliers worth adopting.

By setting measures and monitoring a supplier’s adherence to an established contract, organizations reason, they can ensure that a supplier delivers the product at the lowest cost.

This is not surprising given the impact that procurement and supplier performance can have on the bottom line.

What organizations neglect to consider is whether such a limited approach to managing suppliers is the best to use for all supplier relationships.

APQC, in collaboration with Kate Vitasek, Emmanuel Cambresy, and Bonnie Keith, suggests a more nuanced view of developing and managing supplier relationships.

APQC recommends that organizations weigh whether traditional SRM focused on cost and compliance is the best approach to use with all suppliers, instead of mainly with transactional suppliers.

For suppliers that are more integral to an organization’s success, provide a highly specific product, or have the potential to develop innovations that can benefit both parties, APQC recommends the development of a more strategic and collaborative relationship business model.

Benefits of Supplier Relationship Management

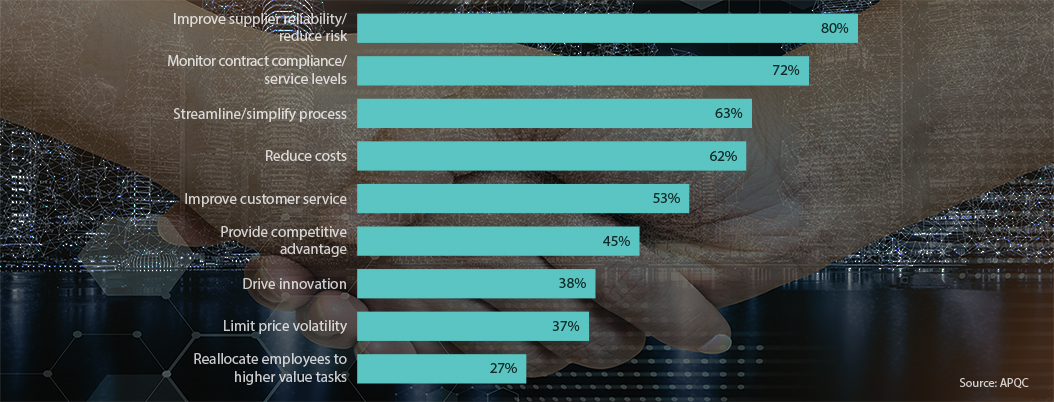

When asked to consider the benefits of widespread deployment of SRM, respondents to APQC and SCMR’s survey rated tactical benefits the highest.

Most survey respondents consider the day-to-day benefits of implementing SRM across their supply base. The most commonly held benefit is the improvement of supplier reliability - or the expectation that managing supplier performance through standard measures will motivate the supplier to perform consistently.

Figure 1 | Benefits of Widespread Deployment of SRM in the Supply Base

Many organizations also consider the ability to monitor a supplier’s adherence to the contract, as well as its own ability to simplify monitoring processes, to benefits resulting from SRM.

To a lesser extent, organizations see the potential for SRM to result in an additional competitive advantage, innovation, pricing control and the ability to allocate employees to higher value tasks. With many suppliers providing organizations with materials key to their mutual success, using the relationship to develop mutual benefit is far more impactful.

In fact, APQC’s opinion is that traditional SRM limits both buyers and suppliers by forcing them to have a relationship focused on contract compliance and on measures related to pricing and cost.

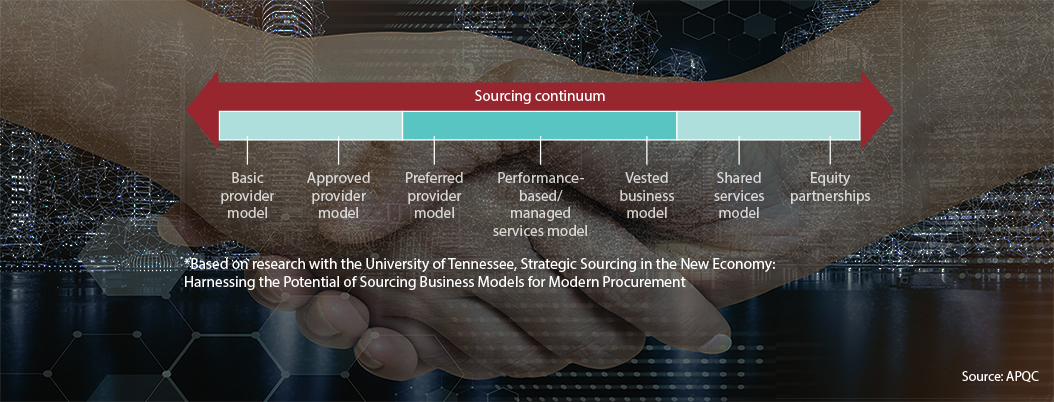

Research by the University of Tennessee reveals that it is more accurate to view sourcing business models, and thus supplier relationships, as existing on a continuum (Figure 2), with one end representing a basic provider model.

This transaction-based model is best suited for traditional SRM approaches focused on price because products purchased are readily available from multiple suppliers and transitioning from one supplier to another would have little to no impact on the business.

On the other end of the continuum is an equity partnership model, in which a supplier and organization invest in creating a joint venture to ensure that they can acquire or co-create mission-critical goods and services.

In the middle of the continuum are sourcing business models based on increasingly collaborative relationships, a group of models in which the buyer and supplier establish mutual goals and ultimately generate benefits for both parties.

Figure 2 | Sourcing Business Models

With these types of win-win supplier relationships (e.g., preferred provider, performance-based/managed services and Vested), organizations can obtain the more strategic benefits seen to a lesser extent by those organizations using traditional SRM methods across their supplier base.

Hurdles to Supplier Relationship Management

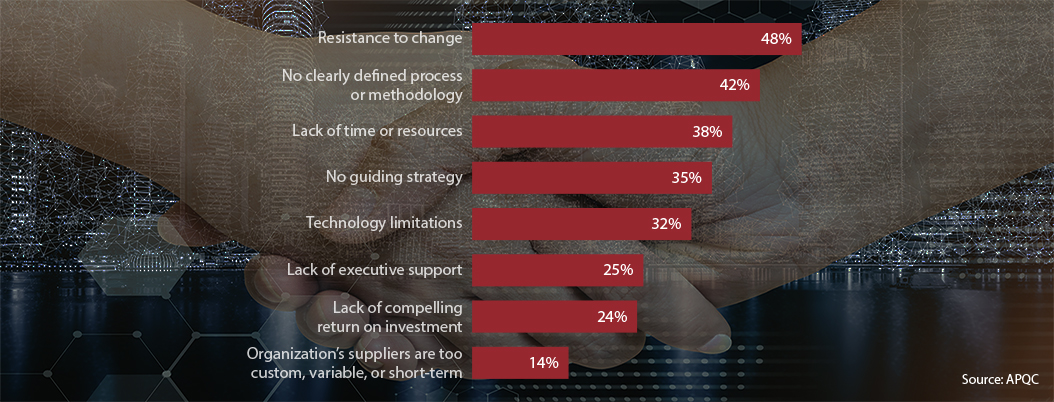

Respondents to the survey conducted by APQC and SCMR also noted hurdles to widespread deployment of SRM for their supplier base.

As shown in Figure 3, one of the top hurdles seen by respondents was a lack of a clearly defined process or methodology for managing suppliers. Over one-third of respondents also saw a lack of a guiding strategy for supplier relationship management as another hurdle.

Going beyond traditional SRM to use a sourcing business model approach with key suppliers can address the lack of methodology and guiding strategy for supplier relationship management.

For supplier relationships at the relational or investment level, buyers and suppliers establish joint goals at the start of the relationship that are tied to both parties’ definition of success. This provides a clearer idea of how to determine whether the supplier is performing at a level needed for a successful relationship.

Although reported by only 14% of respondents, having suppliers that are too custom, variable or short-term can also be addressed using the sourcing business model continuum developed by the University of Tennessee.

In a Vested model, for example, a key supplier collaboratively defines the goals and thus the measures that fit the services provided in that unique relationship, no matter how different it may be compared to others.

Figure 3 | Hurdles to Widespread Deployment of SRM in Supply Base

Flexibility and Mutual Benefit

Developing the right kind of supplier relationship based on the right kind of sourcing business model moves an organization from traditional SRM to the next generation.

Although it does take some time and effort to determine the most appropriate sourcing business model to use and then develop a collaborative relationship that benefits both parties, the payoff does exist for organizations that look beyond the traditional approach for managing supplier relationships.

Real-life examples exist of how organizations can re-evaluate and adjust their supplier relationship management. Swedish telecom company Telia Co. AB evaluated its suppliers to determine which would be good candidates for a Vested sourcing model, a relational model in which both parties enter into a collaborative relationship that creates value for both.

This partly involved determining which suppliers would be considered experts in their field, meaning that these suppliers would not need to be micromanaged on how they achieved their objectives.

Download the Case Study Telia and Veolia: From Supplier to Strategic Partner

Dell worked with its reverse logistics provider FedEx Supply Chain to shift to using a Vested sourcing model with outcome-based measures focused on transforming processes. The decision to go this route was made after both parties realized that keeping a sole focus on cost was damaging their buyer-supplier relationship and was no longer leading to new savings.

One benefit to viewing sourcing relationships on a continuum is that organizations can re-evaluate the relationship with a given strategic supplier as circumstances change. As with Dell, an organization looking to shift the nature of a relationship can easily do so by comparing the current sourcing business model used with the supplier to models further along the continuum.

Not only does this approach benefit the business overall, but also staffing levels for sourcing and supplier management. By sorting the more transactional relationships from those that are more collaborative and strategically focused, the organization can allow staff to focus their efforts on relationships that require more attention.

Download the Case Study: How Dell and FedEx Supply Chain Reinvented their Relationship

About APQC

APQC helps organizations work smarter, faster, and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org, and learn how you can make best practices your practices.

Related Article: The Right Solution for Contractor and Supplier Management

Related White Papers

Supplier Management: The Best-in-Class Approach to Drive Performance

This report examines the comprehensive approach, taken by the Best-in-Class, toward Supplier Management, and begins with supplier selection, followed by establishing and measuring key performance metrics and ends with focusing on visibility with their suppliers to ensure ongoing success. Download Now!

Avetta's Auditing Service Accelerates Screening Process for Qualified Contractors

This case study shows how with the Avetta network, DocuGUARD, AuditGUARD, and InsureGUARD, Vertical Limit improved search efficiency by over 50% with instant access to thousands of contractors across the U.S., and reduced supply chain risk with in-depth supplier audits and verification of contractor safety compliance and insurance. Download Now!

Unpacking Sourcing Business Models: 21st Century Solutions for Sourcing Services

This white paper is a collaborative effort among the University of Tennessee, the Sourcing Industry Group, the Center for Outsourcing Research and Education, the International Association for Contracts and Commercial Management, and was the inspiration for the 2015 book, Strategic Sourcing in the New Economy: Harnessing the Potential of Sourcing Business Models in Modern Procurement. Download Now!

More Avetta Resources

Article Topics

APQC News & Resources

Talking Supply Chain Podcast: Planning for the supply chain of the future Planning for the Supply Chain of the Future Enhance the Value of Your Supply Chain Supplier Relationships Benchmarks with Becky Partida: Sales order automation benefits the supply chain Millennials in Supply Chain Today’s Millennial Supply Chain Professionals Top Projects for 2016 Supply Chains: Transportation, Sourcing, Resilience, and Inventory Management More APQCLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain