Embracing the Digital Transformation of Supply Chain Planning

Digital transformation is one of the top concerns and areas of focus for C-Level executives, and there is a growing awareness within senior managers that transforming supply chain planning capabilities to take advantage of the emerging technologies will provide a necessary competitive imperative.

In almost every new supply chain focused industry periodical, you will find an article discussing transformation or digitization.

Industry analysts, consultants, solution providers, executives, and practitioners are all focused on how to transition from traditional to more “digital” planning capabilities.

In fact, a Google search using the words, “Digital Transformation” yields 2,800,000+ results.

As a supply chain practitioner, it is critical to understand what digital supply chain planning looks like and how to ensure your supply chain is on the right transformational path.

What is Digital Transformation?

Digital Transformation involves a focused effort of activity across multiple processes that accelerate performance and delivers new value-added capabilities.

Digital Transformation in supply chain planning usually involves the development of new tools, skills, and/or processes that target a step change in speed and/or agility.

Why is Digital Transformation Important?

Digital transformation is one of the top concerns and areas of focus for C-Level executives.

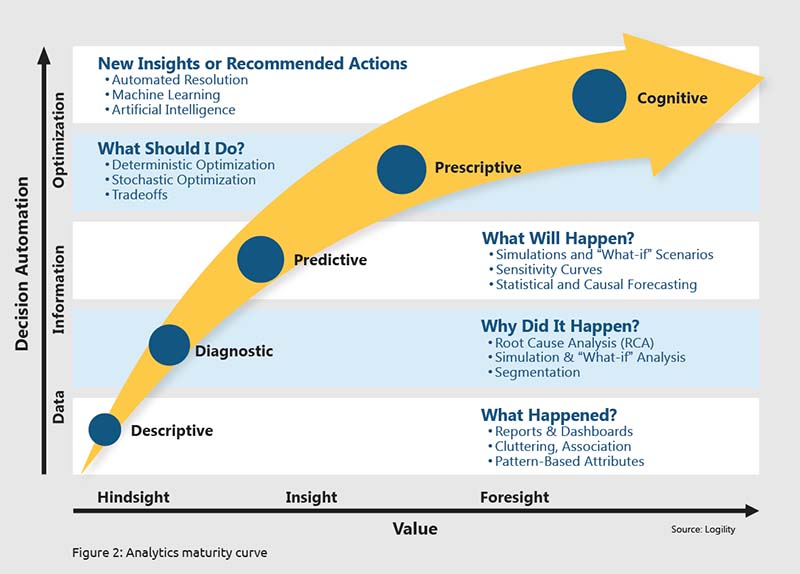

There is a growing awareness within senior executives that transforming supply chain planning capabilities to take advantage of the emerging areas of “Big Data,” “Artificial Intelligence,” “Advanced Analytics,” and “Cloud Computing” is a competitive imperative.

Most supply chain managers already know that there is a “War for Talent” being fought to find and retain qualified supply chain personnel.

Today there is only one qualified supply chain candidate for every seven planning openings and this ratio is projected to increase before it gets better.

The best supply chain planning candidates want to work with advanced technology platforms that allow them to spend more time analyzing problems and developing value-added recommendations.

The digital transformation of supply chain planning capabilities is critical to hiring and retaining the best talent.

Supply chain practitioners are being asked to accomplish more with less, to be involved in more business processes and deliver more value-added capabilities while lowering costs and ensuring high customer service.

Materials and components are sourced from ever-more remote locations and finished products are being sold into expanding regions and channels. The amount of external data continues to grow at exponential rates. Planning cycles continue to shrink and customers expect shorter and shorter delivery cycles. All these pressures demand a step change in performance building the need for Digital Transformation.

As a Supply Chain Practitioner, How Can I Facilitate a Digital Transformation?

The first step is to obtain C-Level sponsorship.

Unlike most supply chain improvement efforts focused on managing and maintaining the current state and making incremental improvements, transformation involves multi-year, multi-functional, disruptive, and expensive efforts that can only be accomplished when embraced by top company executives. Often to gain executive approval requires a business case showing substantial hard and soft benefits.

Start with documenting the “As-Is” process capabilities and corresponding key performance metrics. This will lay the foundation for any future performance comparison and provide the starting point to develop benefits for transformation.

Envision the “To-Be” process capabilities and desired performance metrics through benchmarking group brainstorming sessions, and alignment to business strategy and direction. Include envisioned capability cases to provide a vision of what the “To-Be” environment might look like.

Develop a flexible roadmap with critical milestones required to transition from the “As-Is” state to the “To-Be” vision. The trick is to have enough detail in this transition plan to execute against while still maintaining flexibility to adjust to new priorities and emerging technologies.

The skills people need to operate in the envisioned “To-Be” environment will be drastically different requiring training and education. Some employees will find it impossible to make the transition requiring the hiring of new talent. A dedicated focus on change management and employee development is necessary for successful transformation.

Conclusion:

The move to digital business capabilities is affecting all areas of a company including the supply chain.

Today, technologies such as RFID, GPS, and sensors have enabled organizations to transform their existing supply chain execution capabilities to be more flexible, open, agile, and collaborative. This same type of transformation from embracing digital capabilities is starting to take place in Supply Chain Planning.

To be truly competitive in an increasingly volatile world, forward-thinking companies will need to transform its supply chain planning capabilities by investing in digital supply chain planning capabilities to improve customer service, reduce costs, and enable company strategies.

This new vision of a digitally transformed supply chain has caught the attention of executive management and supply chain practitioners must step up and meet this digital transformation challenge.

Three Checklists to Build a Successful Supply Chain Analytics Foundation

Building robust supply chain analytics capabilities is more important than ever. Economic pressures including rising fuel costs, global expansion, off-shore low cost competition, and tight manufacturing capacities continue to stretch a supply chain team’s ability to reduce costs while meeting ever-increasing customer expectations.

To complicate matters, finding and retaining qualified supply chain talent continues to be an issue. Top supply chain talent tends to migrate to companies that have invested in modern solutions that allow users to spend their time creating value versus shifting through spreadsheets to format, align, validate and report on last week’s data.

To complicate matters, finding and retaining qualified supply chain talent continues to be an issue. Top supply chain talent tends to migrate to companies that have invested in modern solutions that allow users to spend their time creating value versus shifting through spreadsheets to format, align, validate and report on last week’s data.

Download Now: Three Checklists to Build a Successful Supply Chain Analytics Foundation

Article Topics

Logility News & Resources

Logility makes entrance into supply chain-focused AI, with acquisition of Garvis Logility Acquires Generative AI Supply Chain Planning Firm Garvis Supply chain software platforms help to level the playing field Logility to acquire supply chain network optimization vendor Starboard Solutions Logility partners with Körber to expand capabilities How Does IKEA’s Inventory Management Supply Chain Strategy Really Work? This is Not Your Father’s Inventory Optimization More LogilityLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain