Discover How Procurement is Driving Sustainability

GEP sat down with Courtney Wright, chief procurement officer of Veolia North America to learn more about how procurement is supporting Veolia’s mission of reducing their CO2 emissions to net zero and to support their customers’ efforts to do the same.

Discover How Procurement is Driving Sustainability at Veolia

Veolia is the global benchmark company for ecological transformation.

Operating on five continents with nearly 220,000 employees, the group designs and deploys practical solutions for water, waste, and energy management that contribute to a radical turnaround of the current situation.

Veolia recently merged with SUEZ group, the French-based environmental services leader, doubling its size.

To learn more about how procurement is supporting Veolia’s mission, GEP sat down with Courtney Wright, chief procurement officer of Veolia North America (VNA), named the largest U.S. environmental services company by Engineering News-Record to discuss their mission of reducing their CO2 emissions to net zero and to support their customers’ efforts to do the same.

Courtney Wright, Chief Procurement Officer, Veolia North America

Courtney Wright joined Veolia in 2016, currently manages the procurement organization of Veolia North America, and leads a core team of 25, supporting 2,000 purchasers, enabling an organization of 10,000 employees to deliver essential environmental services.

Q. What Does Veolia Do?

We may be one of the largest companies in the world that people haven’t heard of in North America. Veolia is a world leader in delivering environmental services, helping organizations reduce their environmental footprint in three core areas: water, waste, and energy.

We help companies manage, source, and switch to cleaner energy; municipalities and cities with their public drinking water and wastewater treatment plants; and enable companies to manage and dispose of waste properly, especially hazardous waste so it’s not causing long-term environmental harm.

Q. Describe your Team and Mission

Our mission is to provide efficient, easy-to-use procurement solutions that help the business maximize the value derived from every dollar spent on goods and services.

We manage all facets of the source-to-pay process, encompassing sourcing, contracting, purchasing, risk management, and everything in between for our North American business. Our core team is about two dozen talented professionals who support more than 2,000 purchasers across the company.

I’m an engineer by training and have spent most of my career in chemical plants and field operations. It’s been a great opportunity for me to switch to corporate procurement and apply those skills in a new way, especially in support of Veolia’s customers, who are working to mitigate the environmental impact of their activities.

Q. What Are Your Big Categories of Purchases?

Beyond energy and utilities, chemicals are a significant category, followed by transportation.

Because we provide service to customers at hundreds of different locations, transportation, logistics, and fleet are essential.

Q. How do you Track Procurement’s Contribution?

Financial metrics are and will remain, key. Demonstrating savings is a principal reason why our team exists.

Veolia has a large diversity, equity, and inclusion program both internally and externally, so increasing supplier diversity and creating a more inclusive supplier network to reflect the communities in which we serve are other important non-financial ways we contribute.

We also help our business development teams partner with our suppliers to create and land new sales opportunities.

We’re not just the team who helps buy stuff, and when we’re engaged earlier in the business processes, we’ve proven that we can provide more strategic support.

Q. How are you Managing Risk?

Our primary vehicle is to make certain we have the key provisions in our contracts to protect against all the various risks, whether something as basic as insurance and liability or more nuanced and complicated like personally identifiable information (PII) and data privacy.

We use standardized contract templates to simplify the process and keep us organized. Procurement is the liaison between all the other business functions.

We also try not to make contracts overly one-sided. While we always protect ourselves, we’re also mindful that our supplier has the same kinds of needs. By finding a fair and equitable balance, we aim to build real partnerships with our suppliers.

Q. What are your Environmental, Social, and Governance Goals?

Our goal is not only to reduce our CO2 emissions to net zero but to support our customers’ efforts to do the same.

We’re looking to purchase and, in some cases, produce renewable energy, and not just buy the least expensive option. It’s no longer just what we buy. How goods and services are made is starting to play a central role in our sustainable purchasing strategy.

Your Partner for ESG Excellence

Drive value and build resilience with our supply chain and procurement sustainability solutions

These aren’t just good-to-have goals anymore.

Environmental, social, and governance (ESG) best practices sit at the heart of business strategy today as companies respond to new expectations of consumers, investors, governments, and employees.

Enterprises striving for continued growth and cost reduction through operational efficiencies must also adhere to the UN Sustainability Development Goals, COP26 declarations, and the 2015 Paris Agreement, on top of regional and local regulations. In fact, achieving sustainability and building business resilience go hand in hand.

However, when it comes to supply chain and procurement, enterprises face a complex network of priorities and expectations that can make sustainability increasingly challenging, because of:

- A fragmented technology landscape that limits collaboration with the supplier ecosystem

- A lack of skills toward embedding ESG in procurement and supply chain roles

- Misaligned key performance indicators (KPIs) that overemphasize short-term business results

- Low visibility and traceability across the supply chain on ESG KPIs

- Differences in regional ESG policies, priorities, and cultures

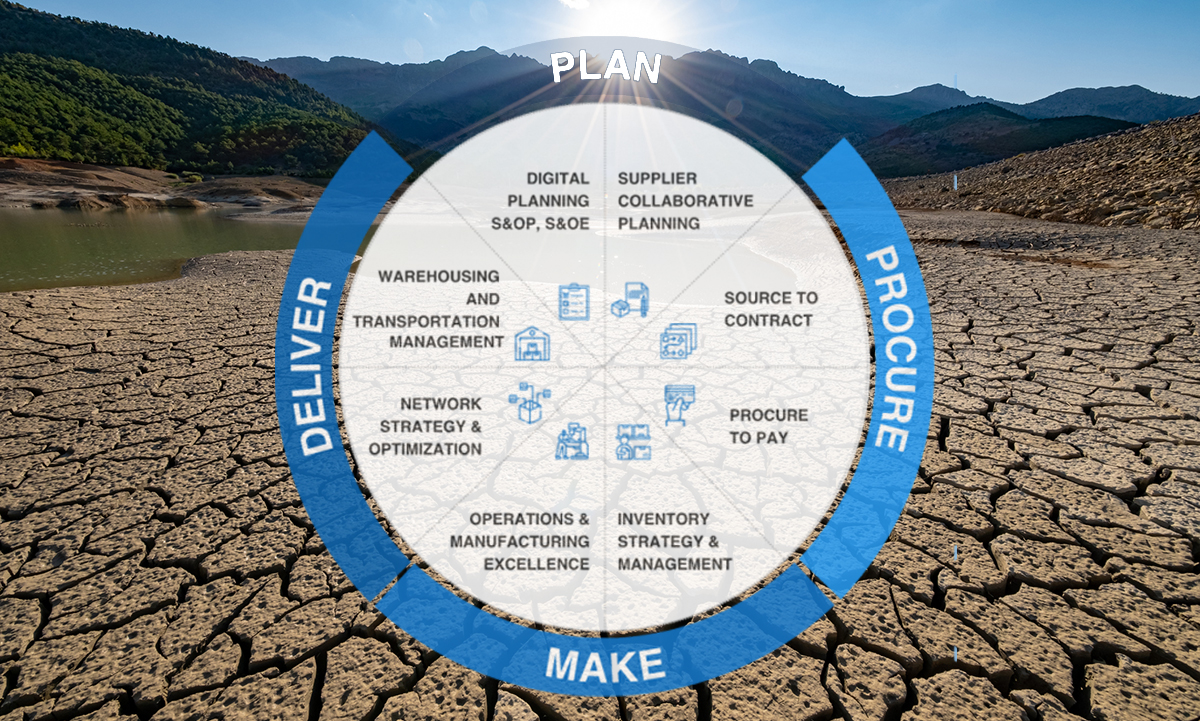

Our Approach

GEP partners with leading enterprises to enable their procurement and supply chain functions to drive organization ESG goals across the value chain.

We execute best-in-class strategies and develop benchmarks for enterprises to become ESG leaders. We also provide the right technology needed to sustain ESG improvements and become more efficient while tracking and tracing results.

Environmental

Optimize the supply chain to achieve net zero emissions, drive circularity, minimize Greenhouse Gas (GHG) emissions and resource depletion, and partner with suppliers who do the same internally.

Social

Partnering with suppliers that contribute to improving social equality, whether that be a small business, minority-owned, or other socially relevant criteria (from supply base to customer responsibility).

Governance

Procurement and supply chain as key drivers to set and execute a sustainable strategy, including mitigating threats and high-risk areas, implementing policies across the supply chain, and driving innovation with external ecosystems. Measure progress and be transparent about Environmental, Social, and Governance (ESG).

Why GEP For ESG and Sustainability Consulting?

End-to-End Solutions

GEP offers consulting services, execution, and technology to help clients drive sustainability across their supply chains. In an area driven by reporting and public disclosure, we help companies baseline, track, strategize and execute ESG plans for faster progress.

Procurement and Supply Chain Expertise

With our long experience in managing over $300 billion in spend, eight million supplier relationships, and analyzing spend of over $3 trillion, we have the data to draw unparalleled insights into how industries can make an environmental and social impact across their supply base.

Actionable Solutions

GEP goes beyond strategy development to support our clients with customized sustainability consulting solutions through implementation. This is critical for progress toward ESG goals given the tight timelines and the public nature of goal setting.

Diverse Leadership and Culture

As a minority- and women-owned organization, GEP understands the value that comes from diverse minds and backgrounds, and this is key to our ESG strategies.

Global Footprint

Our teams spread across the world have deep knowledge of local and regional requirements and collaborate to share best practices and stay ahead of the curve on best-in-class ESG practices.

Talk to Our ESG Experts Today! Contact Us

Talk to Our ESG Experts Today! Contact Us

Q. How do you Track Suppliers’ Impact on the Environment?

Just as everybody is trying to do right now, we want to better understand our suppliers’ CO2 footprints. The key to success is to collect environmental data from suppliers in as easy a way as possible so that we can then take action.

We use questionnaires and digital tools to get the right information from suppliers about their impact on the environment, their improvement plan, and where they are in their journey.

Because it’s a journey for all of us. Not everybody’s in the same place. It’s about ensuring and supporting suppliers’ continuous improvement. We’re also investing in technology to help make suppliers’ data more visible. We want to go deeper than the summary performance data, we want to work with our suppliers to understand their action plans around sustainability and other risk factors.

Q. How are you Mitigating Rising Costs?

The key to success is working closely with our suppliers. We’re not able to offset everything. That’s just the reality of the current environment.

We work to balance suppliers’ needs with our own to keep costs down. Understanding each supplier’s situation helps us understand what costs can and can’t be mitigated.

Moreover, if we do have to pass on price increases to our customers, understanding the why, the source of that increase, and what’s going on in that market helps us inform our stakeholders.

It’s all about effective partnership and communication. The past several years have dramatically increased the need for communication. My team has spent a lot more time not only talking to suppliers but also with our internal stakeholders.

There’s a lot more interest among our business leaders about what’s going on in the marketplace. For instance, before COVID our business ordered chemicals, and other than a missed delivery date here and there, it was uneventful.

Today, our business partners want to know the market intelligence on specific chemicals, where things are trending, and when inflation will decrease.

Our business partners are looking for an entire set of information from us, and candidly we were not really prepared for those questions at first. While our team was collecting the information for our own uses, we weren’t prepared to package it up and share it with our internal stakeholders.

It’s been a good lesson for us to proactively communicate, try to anticipate the questions from across our business, and be prepared in case of an incident or a supplier has a shutdown or some kind of emergency.

Communicating early and often to our stakeholders about what’s happening and is likely to happen goes a long way toward keeping everyone focused, reducing risk, and being better able to manage projects.

Knowing is half the battle. And while it’s taken a lot of time and resources, anticipating issues and proactively communicating have been good learning for us, and one which we plan to continue even after the economy calms down.

Q. Are you Seeing Price Increases Abate?

Overall, it seems like many categories are beginning to stabilize.

While prices aren’t necessarily coming down, we’re not seeing escalating prices in the same way as we experienced last year.

Q. How is Technology Enabling Procurement?

We’ve just gone through a significant digital transformation, updating our ERP platform and purchasing system. We started at the beginning of last year and completed the rollout this year. It’s really satisfying to move past the implementation phase, get everything stabilized and start to optimize our systems and tools to their fullest capability.

Some of the biggest benefits of digital transformation are data visibility and process efficiencies. For example, when all employees are able to use the same expense reporting system, you are able to more easily get a true picture of compliance with the purchasing policy.

You are also able to trend non-compliant purchases and look for patterns of behavior that may indicate a need for additional training or other support.

Automation yields efficiencies, such as the use of OCR technology to eliminate manual entry tasks related to invoice processing. These time savings can be reinvested in other, more value-adding activities.

Thoughts on the Future of Environmental, Social, and Governance

Jagadish Turimella, COO and Co-Founder at GEP explains how and why organizations have shifted their focus from financial performance to Environmental, Social, and Governance (ESG) performance, and debates whether CEOs and corporate executives are doing enough to fulfill their ESG/UN SDG goals.

Q. What are the Key Lessons from your Recent Software Upgrade?

We were a little pressed for time for various reasons during our implementation and had to make some choices on configuration, and we’re only now learning that the consequences of those choices might be slightly different than what we thought they were going to be.

As a result, we are going to do a little bit of rework to make things easier for our end users. It’s all fixable, but if I had to do it all over again, I’d add a few more months, in the beginning, to really dig into the implications of our decisions on end users.

<Q. As you Look Ahead, what are your Biggest Challenges?

We merged with SUEZ last year, which was a huge opportunity and very exciting for us. We’re focused on creating the synergies from bringing our two organizations together as one exceptional company. Beyond the tremendous number of contracts to review as a result of the merger, we’re focused on optimizing procure-to-pay and making certain we have a streamlined and efficient process.

We also need to ensure we continue to build effective communication between procurement and different functional groups, such as operations and finance. Our other top priority is to significantly increase our spending with diverse suppliers over the next few years.

Q. What are the Top Skills that you’re Developing in Your Team?

First, procurement professionals are problem solvers. So, having a critical thinking skill set and being able to take multiple competing priorities and put them together into one solution is really an essential skill.

Second, being able to communicate effectively internally with all employees. Our team needs to be able to communicate across the entire organization, from executives and business leaders to the frontline employee in the field who are doing the ordering. Regardless of who we’re talking to, our information has to be clear and contain the right level of detail.

Q. What is your One Piece of Advice to Procurement Leaders?

In terms of securing support for our transformation, a big win for us was figuring out how to take procurement value and express it in financial terms. Even non-financial metrics can usually be converted into or equated to financial terms.

For instance, conveying “efficiencies” as “time savings” turns labor hours into dollars and puts what we do into the language that business speaks, which goes a long way toward getting buy-in for what you’re trying to do.

Something else we did is to demonstrate the ROI of any investment in our team. Explaining the business case for investing in procurement resources, as well as systems, enables the business to formally evaluate the benefit of, for instance, another category manager or another analyst and compare it against other projects competing for the same funds.

About Veolia

Veolia Group aims to be the benchmark company for ecological transformation. In 2022, with nearly 220,000 employees worldwide, the Group designs and provides game-changing solutions that are both useful and practical for water, waste, and energy management.

Veolia Environnement (Paris Euronext: VIE) generated consolidated revenue of €28.508 billion in 2021.

Read: Veolia, the Leading ESG* Company for Meeting Environmental Challenges.

Related Resources

10 Crucial Steps to Prepare Your Supply Chain for The Circular Economy

This paper is a must-read for procurement leaders looking to revamp their approach to sustainability using a circular model, to reimagine their approach to supplier relationships, sourcing materials, product life cycles, recycling, and business plans. Download Now!

Operationalizing Climate and Social Goals in Supply Chain Operations

This report by Harvard Business Review Analytic Services and sponsored by GEP dives into issues companies are facing as they embark on a sustainability journey, identifying what they need for effective execution to achieve ESG goals. Download Now!

GEP Outlook 2023 - Supply Chain & Procurement: Key Trends, Challenges, and Opportunities

Find out why leading firms are getting used to changes within the supply chain and why they aren’t being knocked off their balance like they were in the unfolding of the global pandemic and how they have become more resilient and more focused on the customer's needs. Download Now!

More Resources from GEP