Delivering pills on demand: Automation and digitization in pharmaceutical market

New industry regulations, the consumerization of healthcare, and the persistent need to replace antiquated logistics approaches are pushing pharmaceutical companies to integrate more technology, automation and digitization into their end-to-end supply chains.

As the critical link between the laboratory and the marketplace, the pharmaceutical supply chain is undergoing some major shifts. As manufacturers develop and market new medicines to help cure myriad conditions and diseases, they face many fulfillment and distribution challenges that range from avoiding shortages and minimizing product expirations to ensuring temperature control during shipment and effectively managing warehouse and DC operations.

Implementation of the Drug Supply Chain Security Act (DSCSA), which outlines product-tracing requirements for manufacturers and their supply chain partners, hasn’t made the situation any easier. The problem is that end-to-end pharma supply chain visibility remains a key challenge and namely because it involves global trading partners.

As these companies look internally at how to improve their supply chain activities and visibility, pharma companies are also answering to a higher calling: patients that want—and expect to have—single orders shipped to their doorsteps.

Defined by PwC as “the acknowledgment of the growing role of consumers and the need to develop strategies and market offerings that fulfill their needs and preferences and fully engage them in an end-to-end customer experience,” this new level of healthcare consumerization is pushing pharma to rethink and rewire their fulfillment, shipping, distribution and delivery methods.

Key fulfillment trends

Tasked with manufacturing, selling, storing, handling, transporting, distributing and regulating products, the pharmaceutical supply chain is ripe for digitalization and automation, neither of which are being used to any great extent by pharma right now. “Pharma as a whole just doesn’t move too fast,” says Michiel Veenman, Swisslog’s head of Competence Center warehouse and distribution solutions. “Right now, we’re seeing big pressures being placed on the industry in areas of track-and-trace and product serialization.”

Tracking individual packages of medication throughout the supply chain is a big charge, says Veenman, and one that typically includes the manual scanning of every single box. This is one of many realities driving pharma to incorporate the Internet of Things (IoT), automation and robotics into their fulfillment operations. Trends like the shrinking of drug batch or lot sizes and the production of patient-specific medications are also pushing more companies to rethink how they make and distribute their products.

“These trends obviously have a major impact on the supply chain, but also on warehousing and on warehouse automation,” says Veenman. “The pharma company that now has to store and process smaller quantities of the same items—including those made with different materials/formulas—clearly has to change the way its warehouse looks and operates.”

Comparing pharma to e-commerce, Veenman says the two industries share common ground when it comes to fulfilling a higher number of smaller orders and doing it faster than ever. Add complex regulations like DSCSA to the mix, and pharma clearly has its work cut out for it over the next few years.

“Pharma is more restricted than e-commerce is as a whole, but it’s being forced to adapt as quickly as e-commerce is,” Veenman says, noting that most companies have mastered the traditional route from manufacturer to either hospital or pharmacy. However, when there’s an exception to the rule (i.e., a single delivery that has to be shipped to a patient’s home), the distribution process gets more complicated.

“I was at a conference recently where pharma actually talked about using companies like Amazon to handle those small, single orders,” Veenman says. “That was an interesting debate.”

From the vendor perspective, Veenman says Swisslog is helping to ease some of pharma’s pain points by developing more “plug-and-play” type solutions that allow companies to get their automated systems up and running quickly. Faster to install and commission, and requiring less overhead, these solutions help pharmaceutical manufacturers and/or their third-party logistics providers (3PLs) manage relatively small, custom projects in an automated fashion (i.e., short-term contracts with specific customers). “This seems to be at least one of the places where technology is heading,” Veenman says, “with nothing bolted to the floor, easy to install and very modular.”

A leaner, meaner supply chain

As he surveys the pharmaceutical landscape, Softeon’s chief marketing officer Dan Gilmore sees a lot of changes taking place and says most of them eventually wind up making an impact on the logistics and operational sides of the business. For example, he says the shift away from producing large, mass-market, “blockbuster” prescription drugs and over to more tailored options has impacted distribution in big ways.

“Now, and certainly in the future, pharma companies are going to be delivering medicines that are made just for you or just for me, based on our DNA and other factors,” Gilmore explains. “This obviously creates huge implications for the warehouse and for distribution.” For example, he says the production and fulfillment of those personalized medicines could take place under the same roof. “In a big, mass model, you can produce the drugs at one place and ship them other places for distribution,” Gilmore explains. “Effectively managing smaller, more personalized orders, on the other hand, will necessitate closer ties between production and distribution.”

Adapting to these and other shifts could prove difficult for the pharmaceutical industry, which hasn’t paid much attention to logistics costs due to the high value of its products (i.e., a single pill can cost $15 to $20 or more). “Comparatively speaking, shipping has been pretty inexpensive,” says Gilmore. “As a result, logistics costs as a percent of sales (a common metric used by most industries) was very low. Companies didn’t worry about it that much.”

That’s changing. Over the last few years, for example, as the number of blockbuster, highly profitable drugs being made has dropped, more pharma companies are starting to look at their logistics costs. With Amazon acquiring online pharmacy PillPack, the push to reduce logistics costs while decreasing delivery timeframes is gaining momentum. “Everyone knows Amazon is going to introduce a ‘leaner’ model to pharmacy distribution,” says Gilmore. “This is pushing other pharma companies to ask, ‘Okay, so what does this mean for our business, and how do we have to also get leaner and meaner?’”

Pills on demand

As they focus on creating leaner and more efficient supply chains for their products, pharma companies are testing out fulfillment automation and other advanced technologies that can help them work smarter, better and faster. It’s all in the name of being able to “deliver a pill on demand,” says Gilmore, who adds that the industry’s fulfillment models are still plagued by a lot of manual processes and fairly high head counts. “Some of that is related to compliance, but not all of it,” says Gilmore, “since some aspects of compliance can be more automated.”

Pharma is also focused on infusing more supply chain best practices into their operations. Talked about for years but not really put into motion, these best practices incorporate formalized commitments to centralizing distribution for pharmacies—a domain that in the past has fallen outside of the scope of the traditional healthcare supply chain. “With the rising cost of drugs, and particularly in the brand/specialty space, we’re seeing more organizations recognize the need to adopt best practices,” says Jeromie Atkinson, TECSYS’ senior director of supply chain.

Going forward, Atkinson says pharma’s best opportunity to save on fulfillment costs while streamlining the end-to-end supply chain is going to lie in companies’ ability to control their own distribution processes. Some are focused on hub-and-spoke type distribution operations, anchored by a flagship hospital. Others are looking at their DC options, with facilities that are either leased or built from the ground up and then used as distribution points for hospitals, pharmacies and/or patients.

These and other moves are being made in the name of leveraging scale while reducing costs, says Atkinson, who sees technology continuing to play a key role in pharma’s mission to work leaner and meaner. “Automation has helped with workflow,” he says, “while data has helped companies across the entire clinical care continuum effectively leverage that intelligence and make it actionable.”

More automation and digitization

And, as more pharmaceutical companies replace their homegrown enterprise resource planning (ERP) systems with more advanced, modular options, their efficiency levels will likely improve as a result.

“The order management systems that many pharma companies are using were really built for another time and another era,” Gilmore points out, noting that the notion of real-time inventory, network and capacity visibility—combined with current labor market constraints—are all playing key roles in pharma’s push to automate and digitize their operations.

“In the ‘old world’ of pharmaceutical distribution, activity was static, orders flowed a certain way, and time wasn’t of the essence,” says Gilmore, who is currently working with pharma companies that have to move temperature-sensitive shipments direct to consumers using both ground and air. “These meds don’t have a shelf life to survive a three-day trip; they have to be there overnight. These are the kinds of things that no one was worried about five years ago.

Companies mentioned in this article:

Pharmaceutical Products and Accessories

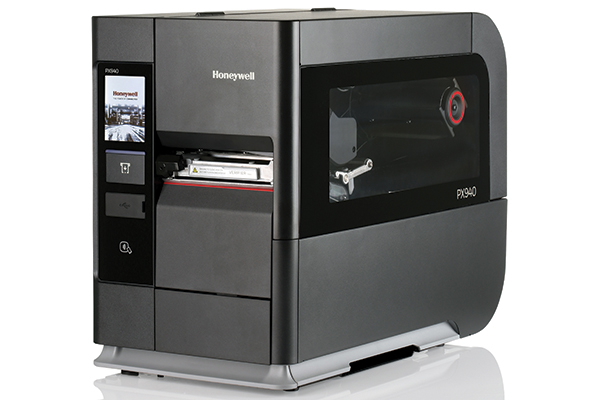

PX940 industrial printer

PX940 industrial printer

Verification system ensures a quality label with every print.

Teklynx Central CFR 5.0 software

Teklynx Central CFR 5.0 software

FDA compliant 21 CFR Part 11 label software

Versa Flex checkweigher

Versa Flex checkweigher

Robust checkweigher now features stainless steel construction.

ATEX-certified bulk storage container heaters

ATEX-certified bulk storage container heaters

ATEX-certified heaters protect and warm drums in hazardous areas.

Reduction factor 1 sensors with IO-Link

Reduction factor 1 sensors with IO-Link

Reduction factor 1 sensors unify switching distances for all metal types.

RightPick

RightPick

Combine traditional automation with traditional workflows.