Breathing New Life into the Retail High Street with Micro Fulfilment Centres & Robotic Automation

Could micro fulfillment centers and robots breathe a new glorious life into the High Street, turning the problem of returns from online retail into new opportunities, I say 'yes they can.'

Can Robots Save the High Street?

I say micro fulfillment centers and robots can breathe a new glorious life into the High Street, turning the problem of returns from online retail into a new opportunity.

I don’t know what it’s like where you live, but where I am, the local High Street is a disappointing shadow of what it used to be.

Once fine shops are now empty shells. Restaurants, cafes, and coffee shops have partially filled the spaces, but stopping for a coffee or a meal whilst out shopping is not so much fun when there isn’t much shopping to be done.

So, can the High Street be saved? I think it can, and the answer lies with robots, micro fulfillment centers, and creating serendipity.

Everybody knows why the High Street is in crisis. The internet has hollowed it out. E-commerce is a great disruptor.

But there is a snag. The disruptor is struggling too. Maybe the disruptor is even being disrupted.

In the UK, for example, the two most famous online retailers, ASOS and Boohoo, have seen share prices crash.

In 2022, it is not unusual for a company to see sharp falls in its shares.

But for ASOS and Boohoo, it has been something else.

ASOS shares have lost around 75 percent of their value since the beginning of the year.

Boohoo shares didn’t fare much better.

Compared to a more traditional retailer, shares in Next, a well-known British fashion retailer with a strong High Street presence and online sales, have fallen but by nowhere near as much.

It is part of a wider trend. As a recent report on Bloomberg said, shares in online retailers like Amazon, Shopify, and Wayfair have seen shares fall by a much higher percentage than the S&P 500.

There is more than one reason why online retailers have had hard years; in part, it seems that Covid did not accelerate the shift online as much as previously expected. As the pandemic eased, online retail has partially shifted back to pre-Covid habits.

But there is another problem, and this problem takes us to the core of this article and why advanced automation and robots, and micro-fulfillment centers are creating this new opportunity.

The Problem is Returns

Boohoo, for example, recently blamed a higher level of customer returns as a partial explanation for disappointing profit projections.

But it is hardly surprising. According to National Retail Federation and Appriss Retail, US retailers expect total returns in 2021 to have increased by 16.6 percent over the year before, hitting US$761bn.

The trend is up. UPS coined the phrase National Returns Day to describe the day in early January when it returns the most packages.

According to Statista, the number of packages returned in the US during the week, including National Returns Day, increased from one million in 2016 to 1.75 million in 2021.

FYI: National Refund Day, 2023, is on February 29th | National Today

The High Street Opportunity

The opportunity comes in the form of local warehouses, served by robots, linked to more old-fashioned physical retail showcases.

The cost of returning goods can be prohibitively high, reducing what are already very thin margins to possibly unsustainable levels.

For the customer, there is a problem, too, one we all intuitively understand - and that is the hassle factor.

Online shopping has the drawback of waiting for a delivery and not being able to obtain the goods you ordered instantly.

The solution lies in local warehouses near your home or micro fulfillment centers.

The customer can order online and either collect from the local warehouse or have the item delivered.

If they need to return the item, they will also have the choice of sending it back or taking it back in person to swap for another item, such as for an item of clothing in a different size or color.

For the vendor, because of the short distances involved in delivering the item and facilitating returns, their costs of delivering and handling returns are reduced enormously.

In short, among the advantages of local warehouses - or micro fulfillment centers - is that they save money for the retailer and provide the customer with the opportunity to collect in person, avoiding the hassle of waiting for a delivery.

This also plays to the issue of carbon footprints; shortening the journey, at scale, is potentially very important.

Upcoming Webinar, co-hosted with MWI - How to Get Internal Buy-In From Key Stakeholders

Queue the Robots

Centralized storage and distribution are not new. Argos in the UK has been operating this way seemingly forever; what is new is the technology used. This is where robots enter the story as the missing ingredient.

Before robots, the cost of providing labor for small local warehouses was often prohibitively high. There are economies of scale in manning a warehouse, which is one reason they are traditionally so large. Robots represent a game-changer. The cost of operating a warehouse efficiently, if need be, 24/7, is transformed.

Today’s robots are highly mobile, dedicated machines powered by data from a centralized control system. This means you can get a few robots to manage the smallest of fulfillment centers, deliver high-end service without the risks, and redeploy them wherever needed.

Furthermore, Artificial Intelligence (AI) can be employed to create improved stock control helping local warehouses anticipate customer demand more accurately, reducing the need to have large warehouses by applying intelligent stock control.

The added opportunity lies in the extra services that can be provided to the customer when they collect or return an item to swap it for something else, in turn creating serendipitous opportunities for the vendor and customer to spot that exciting item - a kind of unexpected inspiration.

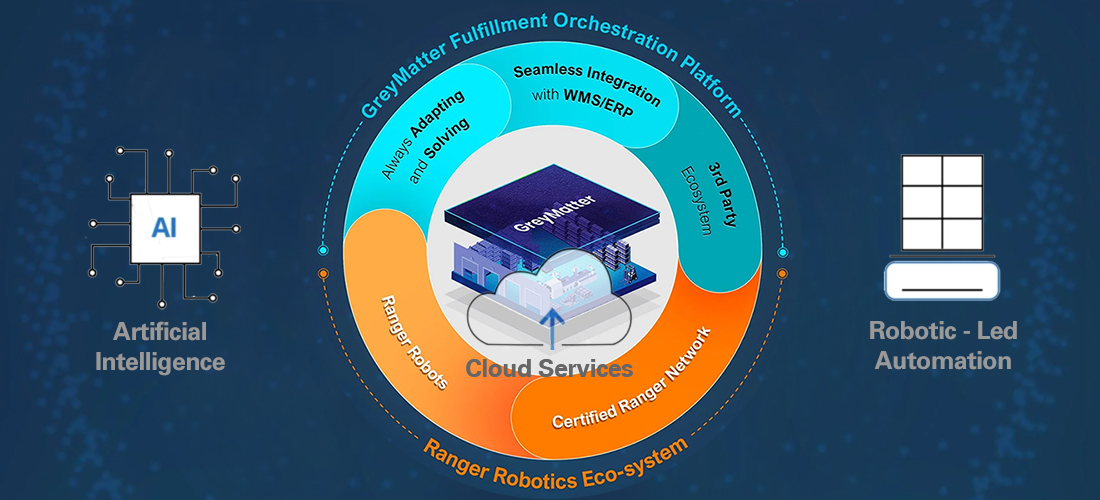

The Automated Fulfillment Robot-Agnostic One SaaS Platform

You cannot meet modern fulfillment demands with technology built for a previous era.

So we combined AI-driven cloud software and smart robotic automation to overcome inadequacies in existing warehouse technology and capitalize on modern market developments.

Imagine this Potential

The potential to use robotic technology and AI to reimagine the high street has never been better positioned than it is right now.

The micro fulfillment center could exist on one floor of a former large store, subsequently closed down. Surrounding this floor, a myriad of opportunities are created for the vendor to upsell and for the customer to re-experience the magic of the physicality of shopping.

Cafes, restaurants, and coffee shops have a new reason to exist. Pop-Up shops could emerge, but there is an opportunity to provide information.

I see shop windows style presentations, showrooms, mannequins, a treasure trove of ideas, an Aladdin’s cave of wonder, pure style - but substance, the actual products, on another floor, stored away, making super-efficient use of space, just a short robot’s journey from the customer’s embrace.

It is an exciting image - a high street that inspires us to think of a modern future, backed by automated warehouses, nearby but not cluttering the aesthetics of a dynamic High Street.

That’s why I think robots can save the High Street.

About the Author

Michael Baxter is a Technology Executive, Corporate Board Director, and currently holds the position of Sr. Vice President - Product Development, GM Bureau Solutions, at Entrust. He is versatile, with expertise in the following tech sectors: cyber security, identity, semiconductor processing, polymers, aerospace, propulsion, automotive, robotics, high volume manufacturing, capital equipment, cloud applications, and IoT. He is a thought leader, having changed the trajectory of companies by formulating and driving bold, differentiated strategies.

Related Resources

Five Priorities for Omnichannel Retail Supply Chains

This white paper identifies five key elements that all retailers should be incorporating into their demand-driven omnichannel supply chain strategies. Download Now!

Leveraging Advanced Automation & Robotics to Grow your Micro-Fulfillment Strategy

In this white paper Patrick Sedlak, Principal at Sedlak Management Consultants, and John Seidl, Partner at GreyOrange Strategic Solutions, provide insights on how to develop the roadmap in support of a micro-fulfillment strategy that leverages advanced automation and robotics to address the immediate needs of the market and consumers. Download Now!

Breaking the Limits of Rigid Conveying and Sorting Using Free-Range Robotics

This whitepaper looks at the technology used for inventory flow in fulfillment centers and factories and how to handle the demand for speed and convenience in a cost-effective way. Download Now!

More Resources from GreyOrange

Article Topics

GreyOrange News & Resources

Autonomous mobile robots (AMRs) on a mission GreyOrange demonstrates results-driven robotics 4 Tech Directions to Shape Distribution Center Performance GreyOrange closes on $135 million in growth financing GreyOrange and Hai Robotics dynamic partnership addresses automated robotic fulfillment Is an automatic guided vehicle (AGV) in your future? Four tech directions to shape distribution center (DC) performance More GreyOrangeLatest in Technology

Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution 80% of Companies Still Unsure How to Best Leverage AI, Study Finds Supply Chain Stability Index: “Tremendous Improvement” in 2023 AI Not a Priority for Retailers and CPG Companies More Technology