Best Practices in Global Logistics

Even though total supply chain costs may be reduced by global sourcing, typically, transportation and logistics costs have been rising as a percentage of the cost-of-goods sold (COGS).

The modern business landscape is marked by increasing levels of global sourcing – particularly from low-cost countries.

While many companies across a variety of industries achieve cost savings through this sourcing strategy, the benefits are often offset by complexities associated with global logistics management.

Even though total supply chain costs may be reduced by global sourcing, typically, transportation and logistics costs have been rising as a percentage of the cost-of-goods sold (COGS).

This has occurred as a result of rising fuel prices, the intrinsic costs of long-distance flow of goods and transportation capacity imbalances – both for domestic transportation in regions like North America, and for international ocean and air freight from countries like China.

Logistics as a Strategic Business Function

Supply lead times often have a high degree of variability, which can lead to poor on-time delivery performance, as well as unavailable products, components and merchandise. The variability in lead times stems from many factors.

The global flow of goods requires multiple handoffs – including various carriers, customs and port authorities, and consolidators. And these hand-offs increase the probability of unexpected events. Growing import volumes, particularly from Asia, combined with important security concerns, have led to severe port congestion in North America and Europe.

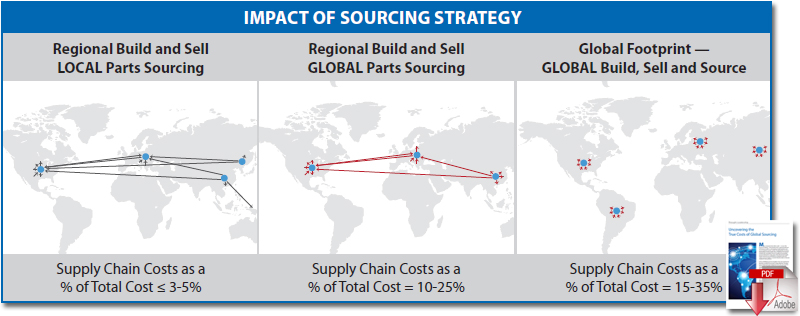

Impact of Sourcing Strategy

As shown above, the percentage of total landed cost that is attributable to supply chain can go from less than 3-5 percent in a local sourcing environment to as much as 35 percent in a global sourcing environment.

As companies conduct business in more countries, and as countries continuously change their regulatory and customs-clearance processes, delays occur during document compliance assessment and processing.

Leading companies are leveraging several strategies to respond to the complexity of global logistics management in an effort to reduce transportation costs and improve service levels while still focusing on the “buy anywhere, sell everywhere” business model.

As a result, logistics is becoming a more strategic business function at companies where it has not traditionally been a core competency.

Here are some key best practices for managing global logistics:

1. Evaluate and determine the right global logistics operating model

Companies achieving success in global logistics are assessing and determining the right logistics operating model, including identifying which logistics functions to outsource and which to keep in-house.

They’re asking themselves: Is it strategic to develop in-house competencies related to logistics network design, logistics sourcing and management, transportation capacity planning, global shipment planning, visibility and event management? Should companies be outsourcing some logistics execution functions, such as conducting prebooking and booking confirmation in ocean transportation, managing export/ import customs clearance and document compliance, and warehousing and storage?

Additionally, global multi-divisional companies are creating a shared-services organizational structure to procure, plan, execute, monitor and measure global freight movements. Global logistics organizations are evolving into “internal 4PL” business models to effectively manage and service the needs across various lines of business and regions.

2. Establish strategic relations with logistics service providers and get alignment on performance metrics

Given global transportation capacity issues and the need for logistics service providers (LSPs) to provide high levels of service, leading companies are elevating their relationships with the service providers to a more strategic level.

“LSPfriendly” programs are being developed to adopt more collaborative rate negotiation and bidding processes, provide forward visibility into logistics capacity needs and develop packaging that allows for easier handling. To streamline their customs clearance processes, topper-forming companies are leveraging customs brokers, freight forwarders and other third parties.

They’re forming long-term relationships with customs officials. Local knowledge can serve as an important lever in avoiding delays and ensuring proper document compliance.

Robust sets of global logistics metrics and key performance indicators (KPIs) are being developed and implemented to score-card LSP performance and continuously monitor performance, as well as align payment terms to these metrics.

3. Deploy global visibility and exception management processes and systems

Visibility into order and shipment life cycles is as critical as third-party partnerships in dealing with the complexities related to global logistics execution. By achieving early visibility into exceptions and proactively alerting appropriate parties involved, companies can mitigate the negative impacts of handoffs and other potentially delaying processes in global logistics.

This visibility and exception-management infrastructure needs to extend across the various legs and milestones involved in the global flow of goods. Visibility by itself is not a silver bullet in solving all complexities related to global logistics. Yet, when combined with intelligent exception management, logistics planning and execution workflows, this layer of global visibility can be a very powerful weapon in managing variability in the global flow of goods.

4. Optimize the global flow of goods through intelligent routing and consolidation

Companies that have large shipment volumes in specific regions are taking greater control of international transportation planning processes. Traditionally, most companies have had fixed business rules to determine routing for specific countries of origin and destination.

Given the need to deal with transportation capacity issues as well as to maximize utilization of containers, they’re now moving toward a more dynamic process – one in which they can make decisions on ports and inland modes and carriers, and look for consolidation opportunities across their international shipment volumes. Leading companies are dynamically evaluating options for doing merge-in-transit, leveraging hubs for pool distribution, doing trans-loading, and diverting-intransit when appropriate to reduce cycle times and costs.

5. Institute a continuous process for ongoing logistics network design and scenario analysis

To fully leverage the benefits of global logistics, companies must continuously evaluate their global logistics network and assess factors such as physical distribution networks, lane structures, mode strategies and capacity requirements. In the past, such exercises were typically done annually or once every two or three years.

However, the rapid pace of modern global business dictates a more frequent assessment of logistics network design. With scenario planning, “what-if ” analysis and management, today’s companies can reap the full benefits and minimize the risks associated with global sourcing.