ASCM & Deloitte Roll-Out Next Generation Digital Capabilities Model for Supply Networks

Business consultancy Deloitte and the Association for Supply Chain Management (ASCM) have announced a new next-generation supply chain model geared towards providing logistics stakeholders with the tools needed to face various supply chain-related obstacles, such as market volatility, digital disruption, and shifting consumer expectations, among others.

New Digital Capabilities Model for Supply Networks

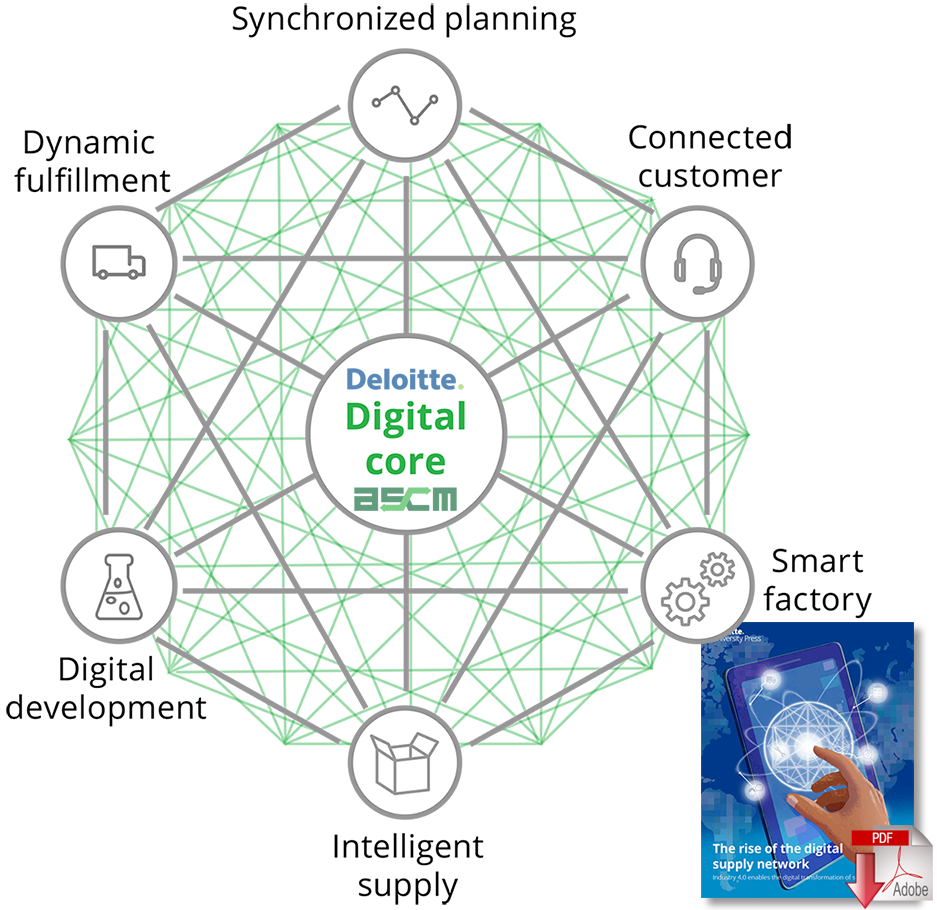

The Digital Capabilities Model (DCM) for Supply Networks, Deloitte and ASCM announced that this offering is designed to help transform supply chain management for today’s increasingly interconnected and digital world.

DCM for Supply Networks is compatible with the Supply Chain Operations Reference (SCOR) Digital Standard, a supply chain framework, linking business processes, performance metrics, practices, and people skills into a unified structure, established by ASCM when it was still operating under the APICS moniker.

And they added that DCM for Supply Networks enables companies to advance capabilities from traditional linear supply chains to digital networks in the form of dynamic interconnected systems that simultaneously plan, execute, and enable digital supply chains.

What’s more, they explained that this offering is geared for any company with a digital transformation focus on its supply chain roadmap, while helping them understand the complexity of digital supply networks and also assess its process maturity.

The impetus for DCM for Supply Networks kicked off about 18 months ago, when the ASCM board initiated a digital task force, according to Peter Bolstorff, ASCM executive vice president for corporate development, with a focus on how to start to think about digital transformation in the future.

“At that time we had created an idea for how we want to update the SCOR model to a digital standard, but then there was also a recognition that we needed to really think about a different paradigm shift on digital capability,” said Bolstorff.

“Deloitte as part of the digital task force, which was the beginning of the collaboration around introducing this very large paradigm shift in thinking about supply chain from a capabilities standpoint…a relational model versus a traditional hierarchical linear supply chain. Our board addressed it in the digital task force, and we updated the SCOR digital standard, and we are excited about this next-gen capabilities model.”

Chris Richard, principal, high tech sector lead for supply chain and network operations, Deloitte Consulting LLP, said that what drove the need to dig into DCM for Supply Networks was the realization that where for hundreds or even thousands of years supply chain management has been under the paradigm of what processes people want to follow, in terms of planning, sourcing material, delivery and managing transportation.

“It starts with ‘what do I want to do?’ and then ‘let me find a technology to make that happen,’” he said.

“The paradigm shift we started to realize a few years ago was that some of these technologies are becoming so powerful and innovative that they now transform how I do run my supply chain. Here is this new paradigm that has been enabled by technology.”

As an example, Richard noted how, for decades, companies were limited to computing power and memory, in terms of how accurate and granular it could be and was linear and sequential. But, now, with computing power so broad, a production plan for all factories can be developed at once and consider all those interdependencies through things like sensors in factories, artificial intelligence, and blockchain, as examples.

“That got us thinking about what we were going to do differently in parallel with what was going on with ASCM,” said Richard.

“We had developed our own internal digital supply networks (DSN) model and started to talk with ASCM about if there was a way to help collaborate there…in taking our starting point and working it into a sort of publicly-accessible open model for digital capabilities.”

As for how the DCM for Supply Networks functions, ASCM’s Bolstorff said it provided models for its members, with three reasons for using them.

One is an investment strategy, with a company thinking about digital transformation but unsure about where it is on a maturity scale or what process approach to take and a need to understand what relationships and capabilities a company needs to be thinking about. The second reason is for a company currently in a transformation plan and how to effectively engineer a successful transformation and ensure success. The third reason is for a company looking for an “outside-in” point of view, which Bolstorff said takes a non-biased approach.

The DCM for Supply Networks model is based on what it calls level one capabilities, which Deloitte’s Richard said serve as a rough equivalent to the SCOR plan, with the addition of connected customer and product development pieces, referred to as dynamic fulfillment.

“For a transportation or logistics professional that wants to understand how to build more of a digital supply capability, when he or she clicks on Dynamic Fulfillment [in DCM], it takes them to level two capabilities like efficient transportation operations and efficient warehouse operations, which are pretty conventional. There is another capability for omnichannel order fulfillment for users to be able to order from anywhere and deliver anywhere, which is sort of a meeting in advance. It is not really addressed explicitly in SCOR, but it is a need.”

Another offering in DCM focuses on abilities that Richard said are more “pushing the edge,” citing interconnected signal transmission as an example, in which DCM is looking at demand and status signals, what truck is a user’s load on, or if an order needs to be replenished, among others.

“What we are trying to do here is provide a range of capabilities that meet very specific needs like trying to take a transportation or warehouse operation to make it more digitally at one end,” said Richard. “And at the other end, what are some different concepts where I can really push the envelope here and function more productively in how I meet my goal.”

Each level capability shows definitions for different objectives as well as drivers for change, what the maturity looks like from early stages to very mature, and a look at a typical day in the life of a person before and after leveraging digital capabilities. These types of things are viewed as digital building blocks for building a supply network, and also how these capabilities relate to each other, noted Richard.

When asked what how DCM for Supply Management serves as an extension of the SCOR model, ASCM’s Bolstorff explained that going back to 1996, when SCOR was launched, that over that time there have been three or four major innovation shifts of the model that really sparked engagement in the community.

“We believe the introduction of these [DCM] capabilities will be at that same level, in terms of a shift,” he said.

“It is not a change that it introducing something absolutely different but compatible. And it really answers the need of our corporate members around what we need to be thinking about from a capability standpoint down to a visualization of how the processes work together. It has really carefully crafted and addressed in a dynamic and synchronous way the way people have to think about the supply chain of the future.”

Principles of the Digital Capabilities Model for Supply Networks

The model will represent capabilities and their interdependencies that transcend physical-digital boundaries and include people, processes, and technologies needed to break through traditional organizational silo’s and be competitive in the digital age.

The model will span supply chain functions to achieve enterprise-level optimization, aligning planning and execution in collaboration with customers, suppliers, and internal facilities. It will detail how to explicitly leverage established and emerging digital enablement, from IoT and sensors to the application of data science, machine learning and artificial intelligence, and lights out supply network planning and execution functions.

Start Your Supply Chain Model Transformation

Are you ready to take the first step on your digital supply chain journey? With our solutions, you can build an ecosystem that connects and automates your value chain.

Digital Readiness Assessment. Take a 10-minute assessment to learn how your organization’s digital readiness capabilities measure up.

The Deloitte Greenhouse® Corporate Innovation Lab. Break down barriers and accelerate meaningful results through one- to two-day interactive sessions tailored to address specific business challenges. The result? Behavioral science, design thinking, and strategy converge to help you solve your toughest business challenges.

- Immerse and inform: Immerse yourself in the details of digital transformation and disruptive technologies that impact the value chain. Inform yourself with a new business and digital transformation strategy, and in-flight initiatives.

- Explore the art of the possible: Explore the importance of integration between operating technology and information technology (including sensor technology). You’ll learn how data and tech architecture are related to the implementation of new use cases. Plus, you’ll discover a selection of value-creating use cases that are relevant to your digital transformation goals.

- Design the path forward: Design a high-level implementation roadmap by prioritizing ideas and business needs. You’ll review case studies of Deloitte’s digital transformation experiences to help inform your strategy. Then, we’ll help conduct an interactive session where potential opportunities are identified and documented. Finally, take part in a discussion on the role people and culture play in the success of the transformative change.

ASCM Transformation Learning Programs: Accelerate your key supply chain initiatives with a proven learning approach. Build organizational capabilities by coaching and mentoring your leaders through a 12-week program across five phases.

- Engage: Engage the team to assess the need for supply chain improvement and gain executive sponsorship

- Define: Capture strategic business priorities, define business goals and set the scope of the assessment

- Analyze: Implement SCORmark, diagnose root causes, recommend improvements, estimate value proposition

- Plan: Plan the portfolio of improvement programs and affirm value proposition versus strategic priorities

- Launch: Confirm value proposition, sponsorship, and resources, and launch implementation projects

Related Article: New Supply Chain Certification Standards for Environmental, Ethical and Economic Practices

Download Related Paper

ASCM Enterprise Certification Standards Guide

The ASCM Enterprise Certification aims to empower organizations to reach their goals, improve results and be more competitive in today’s global business world - through supply chain excellence. Download Now!

More Resources from ASCM

Article Topics

ASCM News & Resources

Supply Chain Stability Index sees ‘Tremendous Improvement’ in 2023 Supply Chain Stability Index: “Tremendous Improvement” in 2023 The Right Approach for Supply Chain Education The reBound Podcast: Innovation in the 3PL supply chain Supply Chain’s Top Trends for 2024 Require Talent Investment for Success Resilience Certificate Now Available from ASCM ASCM conference highlights importance of geopolitics in the supply chain More ASCMLatest in Supply Chain

Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Frictionless Videocast: The Importance of Water at the U.S./Mexico Border with Commissioner Maria-Elena Giner, International Boundary and Water Commission Why are Diesel Prices Climbing Back Over $4 a Gallon? Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws More Supply ChainAbout the Author