An Out-of-the-Box Approach to Material Handling: Innovative Composite Pallet Gains Strength

RM2 has developed a composite pallet that resolves many of the issues the material handling industry faces related to traditional wooden pallets.

They splinter. They warp. They absorb moisture, which can lead to contamination.

The drawbacks associated with the use of wooden pallets go on and on.

But now there is a better alternative: RM2 has developed a composite pallet that resolves many of the issues the material handling industry faces related to traditional wooden pallets.

The BLOCKPal™ pallet from RM2 is pultruded from polyurethane resin from Bayer MaterialScience LLC. Specially designed for use in pultrusion, Bayer’s Baydur® PUL 2500 resin is a two-component polyurethane system that offers excellent composite properties, including superior elongation to failure characteristics, greater shear strength and higher impact resistance.

Unlike pallets made from wood, RM2 testing of the BLOCKPal pallet indicates it is not subject to contamination from bacteria or insects, or splintering caused by rough or repeated handling. In fact, based on its findings, RM2 estimates that BLOCKPal pallets are up to 20 times more durable than wooden pallets. Not only does extending pallet service life minimize costly workflow interruptions, it also helps reduce the need to constantly replace traditional wood pallets.

“Our innovation in materials and design enables our innovation in economics,” explained Niall Carson, business development, RM2. “Because our composite pallets are significantly more durable, we can provide significant economic benefits to our customer base.”

According to Carson, RM2’s out-of-the-box approach relates not only to the pallet material but also to the pallet supply chain: instead of incurring the cost of purchasing and replacing pallets outright, customers lease the pallets from RM2. “We’re changing the way our customers look at pallets – from a consumable to an asset that can generate significant accretive profit margin,” said Carson.

In addition to supplying the custom polyurethane resin system, Bayer also provided pultrusion tooling and process support, part design recommendations, material enhancements and on-site process support. “RM2 is really shaking up the material handling industry with its improved pallet design and innovative business model,” said Paul Platte, market manager – Polyurethane Composites, Bayer MaterialScience LLC. “These composite pallets are just the latest illustration of how pultruded polyurethane is delivering significant value to diverse industries.”

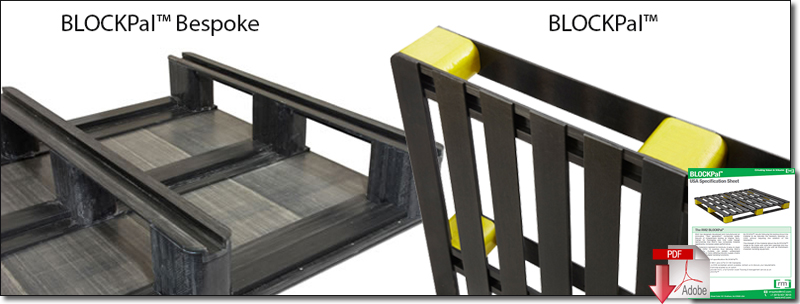

BLOCKPal pallets are available in standard footprints: 1,200 mm x 1,000-mm, 1,200 mm x 800 mm, 1,165 mm x 1,165 mm and 48 in. by 40 in., as well as in customized sizes for specialized applications.

The pallets have been independently tested by leading institutions and, according to RM2, have been shown regularly to outperform comparable products and industry standards. For instance, results following fire testing show the composite pallet passes UL 2335.

RM2 produces the pallets completely in house. The company pultrudes the polyurethane into three basic profiles (feet, slats and channels), paints the feet a distinctive yellow, applies an anti-skid coating and assembles the pallets.

The BLOCKPal™ pallet will be on display at Bayer’s booth (3145) at CAMX, taking place Oct.14-16 in Orlando.

Related: Pallet Survey - How Pallet Trends Stack Up

Article Topics

RM2 News & Resources

RM2 International secures $150 million strategic partnership with Orion Infrastructure Capital Reusable pallet provider RM2 adds Wayne Cochran as COO RM2 opens new hygienic pallet washing facility in Northwest Arkansas MHPN Readers’ Choice Products of the Year winners announced Reusable Packaging Association announces 2017 leadership Pack Expo: RM2 to participate in the AT&T LTE-M network pilot for the Internet of Things RM2 and Jabil collaborate on NA production of pallets More RM2Latest in Warehouse|DC

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring More Warehouse|DC