An Inconvenient Truth About the Produce Supply Chain - Is New Tech The Solution?

Verigo CEO Adam Kinsey describes how the Gainesville company's sensor technology can reduce waste by bringing the Internet of Things to logistics and supply chain management, and after 4 years of R&D, they have launched a leading “pod quality” analysis monitoring device for the perishable supply chain.

It’s happened to all of us; you buy a basket of beautiful berries at the grocery store, and just a short time later you open the fridge and find them moldy and decayed.

And we all know that it’s not just in consumers’ homes; this same spoilage and loss occurs every day in warehouses and stores around the world.

The industry has made great strides in reducing shrink in the last few decades, but it still has a long way to go.

A technology company in Florida is now offering the next step in the fresh produce industry’s battle to prevent shrink and maximize shelf life for end consumers.

Verigo, a startup which spun out of the University of Florida in 2013, is offering a new platform that promises to enable the prevention of at least 20% of today’s fresh produce supply chain shrink.

The industry has used a plethora of devices to monitor and record ambient temperature and humidity during transit for many years.

These devices all do essentially the same thing, and their reports are important for FSMA compliance and useful as an “insurance policy” when things go wrong. After providing wireless systems for temperature and humidity monitoring in over 20 countries, Verigo has now launched something…different.

It's called a “Quality Analysis” platform and consists of hardware and software specifically designed for the fresh produce industry. While it monitors and records temperature, it also does something more. When attached to a pallet of produce, the system's wireless “Pod” devices provide continuous “Product Life” metrics that describe the products' actual remaining shelf life in real-time during storage and transit.

President and Founder of Verigo, Adam Kinsey picks strawberries onsite at a large berry grower during a study of quality management and strawberry shelf life.

“We’re on a mission to improve profitability and customer satisfaction in the fresh produce industry,” says Adam Kinsey, founder and President of Verigo.

“This is the first system that empowers growers, shippers, and retailers with actionable data to optimize post-harvest, inventory rotation, and routing decisions.”

A Problem in Perishables

Over $7 billion (1) worth of fresh food products shipped in North America spoils in the back of a truck or a warehouse before reaching a consumer. Even with the many advances of the modern cold chain, fresh produce often experiences the irreversible quality and shelf life loss at many points between harvest and retail sale.

International logistics and customs add further complexity, and in many cases, it is impossible to identify problems in post-harvest, cooling, and logistics before it is too late. The end result is billions of dollars in losses that can be prevented.

It is well known that temperature control is the most important factor for maintaining quality during long-haul logistics. Fluctuations of even a few degrees in transit completely nullify the benefits of treatments like modified atmospheres (MA) and result in irreversible damage. However, adverse exposures during other stages, such as packaging, processing, and handling, often add up to cause large differences in core product temperatures from pallet to pallet further down the line.

Verigo has seen first hand how these temperature excursions can manifest in a commercial setting. In 2015 a study performed by Verigo in collaboration with a major U.S. grower showed that 27% of pallets were insufficiently cooled during forced-air rapid cooling (2). Even in a high-quality US berry operation with correct SOPs in place, the quality of more than one-quarter of all pallets were compromised in a way that was “invisible” to management and the rest of the supply chain.

And when core temperatures differ from pallet to pallet, you can be sure that remaining shelf-life will vary, as well. A recent study of a blackberry supply chain demonstrated that these variations led to substantial differences in shelf life between pallets of otherwise identical blackberries all sourced from the same farm.

The study showed that “57% of berries arrived at the packhouse with insufficient remaining shelf life for longer transport routes.” (3) With management unable to see or act upon this information, pallets with less remaining life were sent to distant receivers and ended up as a shrink.

Dr. John Ryan, a food safety expert, says “When food enters a transportation arena, it basically becomes invisible. Nobody knows where it is. Nobody knows what conditions it’s being shipped under.” (4) The old adage rings true; you can’t manage what you can’t measure.

Thankfully, it is a standard practice to include a temperature monitor to record the ambient conditions during long-haul transport. The reports these devices create are important records to have in during an audit and in case of a dispute about the condition of a received load.

In practice, though, these devices are often ignored, and the data that we’re paying to collect is often not checked. And when it is reviewed, quality personnel must comb through pages of raw data that only contain the history of that single transport leg.

As a receiver, it is impossible to know the rest of the load's history…what happened to the products in the earlier segments of the chain?

Truth in Transit, a Fresh Solution

A 20% reduction in today’s supply chain shrink will result in $1.4 billion in additional revenue, or enough to provide fresh produce to an additional 1.4 million Americans per year (5). For the team at Verigo, it's their mission to make that a reality.

After 4 years of R&D, they have launched a leading IoT platform built for the perishable the supply chain. When attached at any point in the chain, wireless Pod devices with Bluetooth Low Energy create “smart pallets” that monitor themselves and communicate continuously while in transit.

Logistics and QA staff use mobile apps on Android and iOS devices to access data directly from the Pods during shipping and receiving, and all information is sent to a secure cloud platform for global visibility and automatic record keeping. The purpose of these tools is to empower growers, shippers, and retailers to prevent food waste before it happens and ensure maximum quality and safety for the consumer.

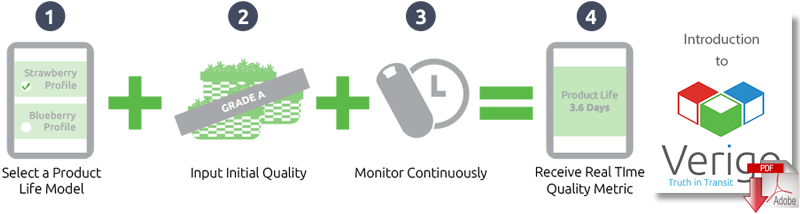

The key to the new Pod Quality monitoring device is the Quality Analysis engine it contains which translates raw sensor data into a single, actionable metric called Product Life. This metric results from the analysis of a number of variables - commodity type, initial quality, and product temperature - and translates them to display the number of days of actual remaining shelf-life of that product.

Leveraging over 30 years of research from the USDA and studies with growers such as Driscolls and Berry World, Verigo has developed a growing library of unique Product Life Profiles which each characterize the degradation characteristics of a particular commodity, from Asparagus to Zucchini.

In a few seconds, a Pod Quality device can be wirelessly configured with the Profile of the specific commodity that it will monitor. A manager can then adjust the Initial Product Life based on the known quality of a particular pallet or load. Finally, the device is activated and placed next to the product in the pallet.

How it Works

From that point on, the now “smart” pallet will record, analyze, and continuously communicate temperature and remaining Product Life to any phone or tablet within ~15 meters. At any point in the chain, staff can use the Verigo mobile app to view the quality and history of the products onscreen, without having to install any infrastructure of antennas, readers, or gateways. And as long as the phones and tablets used by staff have an internet connection, all data is automatically sent to the Verigo Cloud platform and is visible to management anywhere in the world.

For the first time, it is now possible to do much more than monitor temperatures. With access to information about the shelf-life of individual pallets, stakeholders are empowered to make informed decisions that will reduce shrink by 20-40%.

Growers can now see when post-harvest, cooling, and packing operations are degrading shelf-life more than planned and take corrective action. Wholesalers can see the remaining life of pallets in the warehouse, and prioritize the inventory rotation and routing of pallets to minimize rejection. And receivers can begin evaluating the integrity of the products arriving at the dock before an inspection.

Critical decisions aided by the Product Life metrics enable stakeholders to achieve unprecedented insights into the entire supply chain:

- Growers: Superior control of post-harvest, cooling, and packing

- Exporters/Wholesalers: Optimized routing and rotation according to remaining freshness

- Receivers: Streamlined QA and inspections, more robust supplier audits

And ultimately:

- Reduced rejections and customer credit

- Increased revenue and customer loyalty

“This concept [smart shelf-life management] has been around for a long time, but it has never actually been developed and released as a usable product. Now that it’s here, we have an opportunity to change how quality is managed to prevent millions of dollars in shrink, and provide unprecedented quality to consumers. It’s truly a win-win.” states Kinsey.

“Technology has finally made it simple and feasible to monitor from farm to retail on the pallet level. It’s not a matter of if, but when - we’re already seeing these inevitable technology shifts occur in areas like e-commerce and home delivery, and the cold chain is no different. The question is who is, which firms will lead innovation in the industry, and in doing so get a leg up on the competition”.

More information on Verigo and Quality Analysis can be found at www.FarmToForkFresh.com

- United Nations Food and Agriculture Organization Report 2012

- Verigo Large Berry Grower Audit Report

- do Nascimento Nunes MC, Nicometo M, Emond JP, Melis RB, Uysal I. 2014 Improvement in fresh fruit and vegetable logistics quality, berry logistics field studies. Phil. Trans. R. Soc. A 372, 20130307. (doi:10.1098/rsta.2013.0303) Verigo Large Berry Grower Audit Report

- Vicky Nguyen, Jeremy Carroll, Kevin Nious. “Food Giant Sysco Under USDA Investigation.” NBC Bay Area, 29 Aug. 2017. Accessed 29 Aug. 2017.

- Gunders, Dana. Wasted: How America Is Losing Up to 40 Percent of Its Food from Farm to Fork to Landfill. NRDC, 2012, pp. 4–4, Wasted: How America Is Losing Up to 40 Percent of Its Food from Farm to Fork to Landfill.

Related Article: Bringing the Internet of Things to Fresh Food Logistics & Supply Chain Management

Related Verigo Resouces

Pod Quality: Continuous Product Life Data From Farm to Store

This introduction paper provides everything you need to know about Pod Quality, including how it works, features, and benefits. Download Now!

Let’s Build a Smarter Food System

This comprehensive presentation provides an in-depth look into Pod Quality and covers the value proposition, product life models, current solutions, and the Verigo solution. Download Now!

Perishable Supply Chains Pod Quality Auditing Guide

This auditing guide details the perishable supply chains for growers, distributors, and retailers, and how using Pod Quality as an auditing tool makes complex supply chains less daunting to analyze with unprecedented insight and control. Download Now!

More Verigo: Resources

Article Topics

Verigo News & Resources

Walmart’s Eden and Verigo’s Pod Quality: Technology to Reduce Fresh Produce Waste in Supply Chains An Inconvenient Truth About the Produce Supply Chain - Is New Tech The Solution? Bringing the Internet of Things to Fresh Food Cold Chain Logistics & Supply Chain Management Pod Quality: Continuous Product Life Data From Farm to Store Let’s Build a Smarter Food System Perishable Supply Chains Pod Quality Auditing GuideLatest in Transportation

Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Nissan Channels Tesla With Its Latest Manufacturing Process Why are Diesel Prices Climbing Back Over $4 a Gallon? Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws The Three Biggest Challenges Facing Shippers and Carriers in 2024 Supply Chain Stability Index: “Tremendous Improvement” in 2023 Trucking Association CEO on New Biden Policy: ‘Entirely Unachievable’ More Transportation