5 Reasons You Need Integrated Robotic Picking and Mobility

Mobile robots with integrated picking can increase fulfillment throughput at much lower costs than traditional conveyor systems, and in one-third of the deployment time.

Transforming Distribution Centers

Mobile robotic fleets controlled via intelligent orchestration software can transform distribution centers into high-throughput sortation systems with no disruption to existing operations.

Adding robotic picking significantly reduces labor requirements for fulfillment.

With eCommerce revenues expected to reach more than $2.7 trillion in 2021 and continue to climb in the years to come, retail, grocery, logistics, and other businesses must adopt innovative mobile robotic sortation. Why now?

1. Increase Facility Throughput at Lower Costs

Conveyor systems are costly and require months to deploy. And modifying them once built is a nightmare that is cost-prohibitive.

A sortation system with dynamically orchestrated fleets of mobile robots enables companies to set up induct and discharge stations wherever it makes the most sense, use whatever piece of floor or mezzanine is available, and turn any physical site into a flexible cost-effective sortation system.

These fleets of mobile robots are guided via intelligent orchestration software, which continuously learns from goods flows and improves robotic mission time on an ongoing basis - allowing goods to move faster through fulfillment processes.

2. Process More Orders Faster With Integrated Robotic Picking and Mobility

You can implement mobile robotic fleets into your existing fulfillment operations and they integrate with robotic picking systems to deliver faster fulfillment that requires less labor.

Distribution centers are handling more online orders, more frequently now. Robotic picking systems automate the picking and packing of a broad range of SKUs directly into outbound orders, and the mobile bots can more quickly transport the goods across distribution centers, getting them to their destination faster.

With robotic picking systems handling the goods and the mobile robots transporting the goods, distribution centers can be transformed into agile, dynamic environments.

3. Guarantee Always-On Operations While Deploying Mobile Robots

Distribution centers are mission-critical to supply chain operations. And that means downtime is never an option. With a fleet of mobile robots working together with augmented robotic picking if one robot fails or shuts down, another one is instructed by the AI-enabled orchestration software to do its tasks - and the process continues without disruption.

With traditional conveyors, if one section of the infrastructure fails, the entire system would shut down and halt fulfillment operations.

4. Handle the Largest Variety of SKUs, Even Non-Conveyabales

Your fulfillment operations can quickly and safely sort, pick, buffer, and pack SKUs (some considered non conveyable) and increase typical product automation eligibility.

Historically, products such as large bags of dog food or shrink-wrapped cases of water bottles would need to be excluded from conveyor-based systems as they drop down the shoot could puncture the bag or break the bottles, damaging products that need to be delivered to customers.

With a mobile robot, these products can be safely and quickly transported throughout a distribution center without worry.

5. Power On-Demand Capacity When Needed

Online order fulfillment requires flexibility and agility, both things for which conveyor-based systems aren’t well-known. Mobile robotic fleets can deploy quickly, and if order volume increases and more processing is needed, more robots can be easily added. Rolling a new mobile robot out or expanding the sortation floor can take a matter of hours versus months.

Also, mobile robots are available via Robotics as a Service, or RaaS, which allows customers to accelerate their adoption of game-changing automation technology without upfront capital expenditures.

The Time Is Now For Mobile Robotic Operations

Berkshire Grey’s mobile robots:

- Increase facility capacity and throughput

- Integrate with our robotic picking systems

- Deliver the most flexible sortation system you can implement

All of Berkshire Grey’s mobile systems are:

- Dynamically reconfigurable

- Suitable for existing and new fulfillment environments

- Available via both CapEx and RaaS implementation models

Related Resources

Mobile Robots and Their Role in Modern Fulfillment

Learn more about how autonomous mobile robots are the cost-effective and flexible solution for eCommerce fulfillment. Download Now!

3 Myths of Robotic Picking

In this ebook, we detail how scalable robotic systems can help supply chain fulfillment centers and debunk the three most common myths. Download Now!

3 Ways Robotic Package Sortation Reduces Shipping Costs

Improve labor utilization, save on shipping costs, and accelerate delivery speeds by automating package sortation. Download Now!

Retail Store Replenishment Success Story

This case study shows how Robotic Product Sortation Systems were implemented to fulfill store replenishment orders for a fortune 5 retailer and provides 3 reasons retailers need robotic product sortation in fulfillment warehouses. Download Now!

More Resources from Berkshire Grey

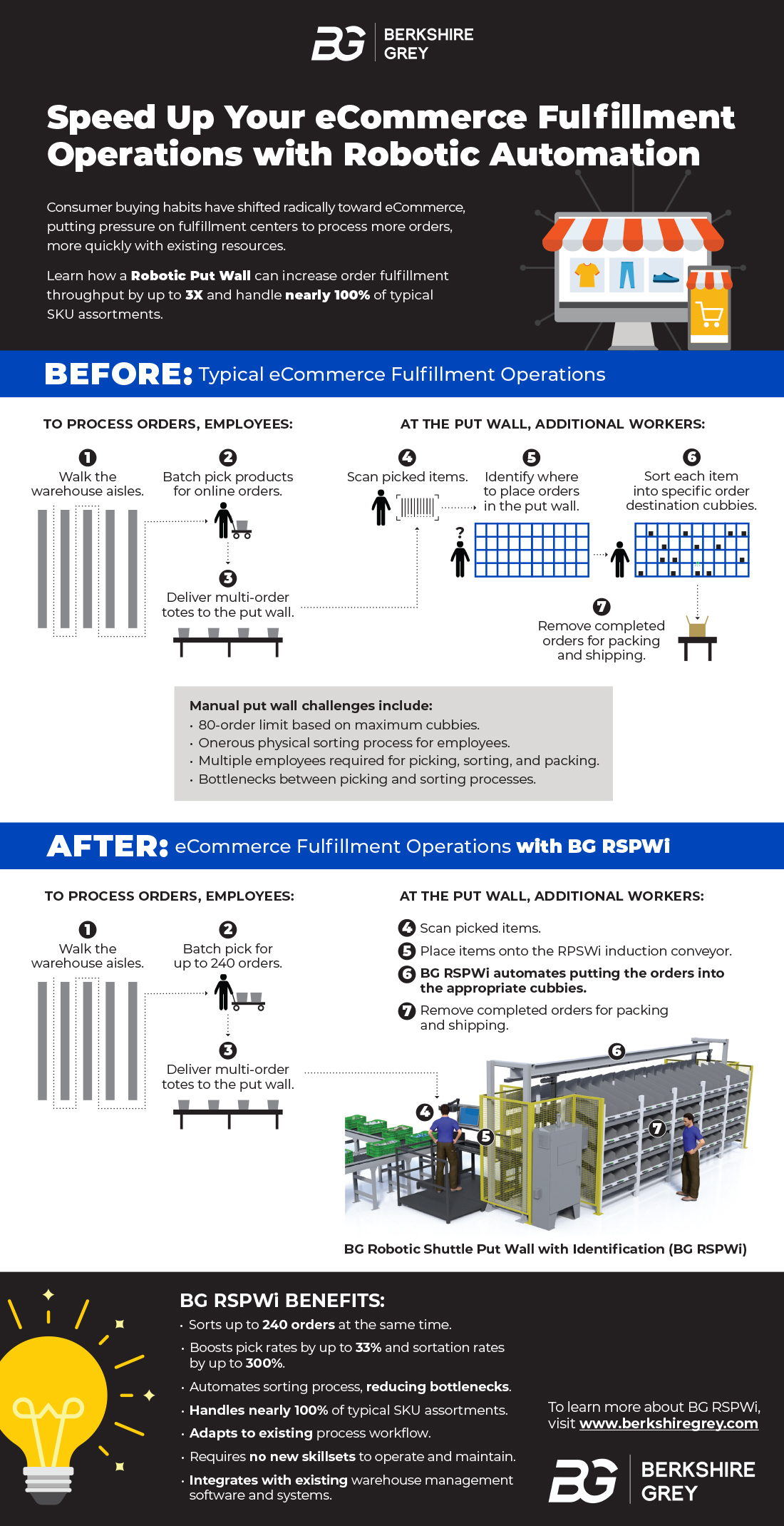

Related Article: Four Reasons to Rethink Your Ecommerce Fulfillment Operations Using a Robotic Shuttle Put Wall

Article Topics

Berkshire Grey News & Resources

Automation is Filling the Labor Gap Ahead of Peak Season ProMat 2023 – Automation at a crossroad Berkshire Grey enters merger agreement with SoftBank Group for go-private transaction Berkshire Grey and Locus Robotics partner to achieve cross-platform robotic automation Amplify your order picking and AS/RS systems with robotic automation Amplify your order picking and ASRS systems with robotic automation Deploy robotic solutions with RaaS to enable worry-free and flexible supply chains More Berkshire GreyLatest in Technology

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology