3PL Partnership Increases Operational Flexibility, Reduces Costs

The challenge was to help a customer maximize an underutilized distribution center and increase operational efficiency.

The past several years have made chemical shippers painfully aware of the market’s unpredictability.

Given the fluctuations in demand, many chemical companies have sought ways to better manage their overhead costs such as warehousing and distribution – arriving at flexible, volume-based solutions.

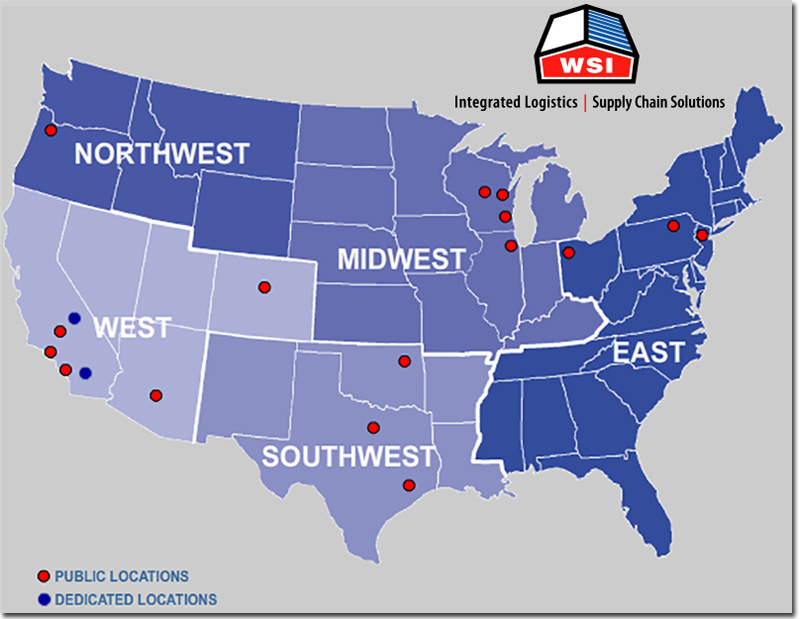

That’s where WSI comes in. The national third-party logistics provider has helped a number of chemical companies consolidate their storage and labor needs, reduce costs and boost operating flexibility.

For example, one of the world’s leading producers of polymers and high-performance plastics has in recent years spun off several business units and reconfigured its supply chain. The company found that it no longer had the volumes to support the large West Coast distribution center it was occupying in the Los Angeles area.

The company turned to WSI for help. WSI assumed operation of the facility, giving the customer much-needed flexibility in storage volume and handling capacity.

“The facility was a fixed cost. We took over the operations and made it a variable cost for them,” explains WSI spokesperson Rob Kriewaldt. “We helped the customer achieve major cost reductions, while we were able to take excess capacity in the facility, utilize it for other customers and expand our service offerings for those customers to include import/export services due to the facility’s strategic location.”

Similarly, when the customer wanted to downsize its East Coast distribution operations, it closed a New York City area facility and moved into a WSI location in Allentown, PA. “In this case, they also wanted flexible space and labor costs. We’ve given them the ability to grow and shrink their space as needed, as opposed to having a fixed cost every month. The chemical industry is very cyclical,” Kriewaldt explains. “Our services allow chemical shippers to tailor their costs to the ups and downs of their business cycle.”

An industry-leading 3PL provider, WSI delivers reliable, end-to-end supply chain solutions for chemical companies and a variety of other customers nationwide. Some of the specialized capabilities that WSI provides its chemical customers include bulk and rail transfers, blending and sampling services, and flammable/hot/cold room storage at secure, compliant facilities located across the U.S.

Article Topics

WSI News & Resources

The Government’s Role in Food Safety How FSMA Will Impact Shippers in 2015 and Beyond Congress Should Prioritize Food Safety Modernization Funding 2015 FDA Regulations will Place new Pressure on Shippers 25 Years of Third-Party Logistics Research & Studies Shippers Condition Index Points to Ongoing Tough Market Conditions for Shippers Intermodal Service Issues Persist But Conditions Are Slowly Improving, Say Carriers and Analysts More WSILatest in Transportation

Ask an Expert: How Shippers Can Prep for Hurricane Season UPS Struggles in First Quarter With Steep Earnings Decline FedEx Announces Plans to Shut Down Four Facilities The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency Baltimore Bridge Collapse: Impact on Freight Navigating Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 More Transportation