3D Printing Operation on UPS Supply Chain Campus

Innovative technology, automation, and colocation on UPS Supply Chain Solutions Campus gives direct digital manufacturer CloudDDM a strategic advantage as they set out to commercialize additive manufacturing.

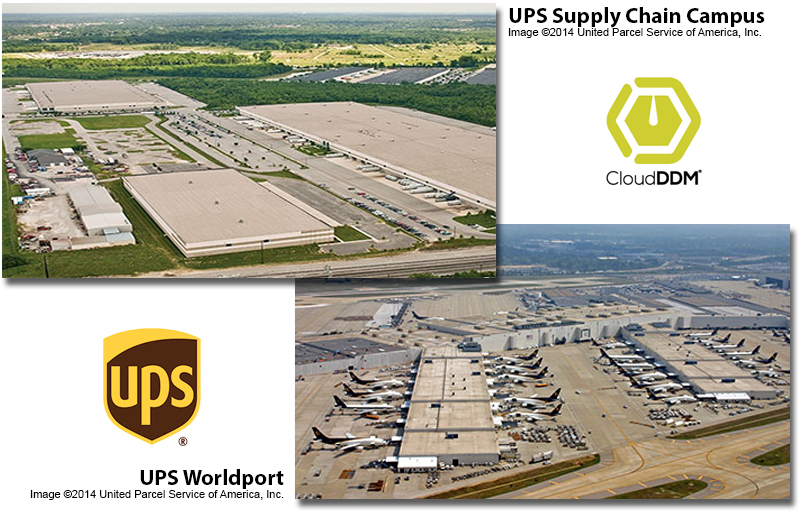

CloudDDM, LLC, a company focused on delivering direct digital manufacturing, DDM, services, announced the launch of its advanced additive manufacturing facility located on the UPS Supply Chain Solutions Campus at UPS Worldport®, the world’s largest packaging handing facility.

“We realized that direct digital manufacturing was the future and a new approach to additive manufacturing would be required in order for the technology to reach its full potential,” commented CloudDDM Cofounder and CEO, Mitch Free. “We believe our approach offers value to start-ups, small companies, and large companies alike.”

Leveraging a combination of innovative 3D printing technology, automation, and location on the UPS Supply Chain Solutions Campus, CloudDDM is eager to provide additive manufacturing services to the growing number of designers, engineers, and companies who want to leverage the benefits of industrial additive manufacturing (3D printing) to reduce upfront production costs, manage stock and inventory, and accelerate product development.

3D printing describes a method where solid objects are built by adding layers of material in a linear process to produce a finished part. This is the opposite of machining, sometimes referred to as subtractive manufacturing, where material is removed from stock to produce a finished part. The advantage of 3D printing is the ability to “print” parts that contain complex geometry or features that would be impossible to produce otherwise, or are simply too cost prohibitive.

Additive manufacturing, or the use of 3D printing technology on an industrial scale, is growing. Some companies today already offer large scale additive services to industry. In addition to offering a broad range of 3D printing methods, these companies offer consulting services to help customers with specific projects and educate them on materials and how to incorporate additive processes into their designs. One aspect of CloudDDM that differentiates it from existing suppliers is its high level of automation, or what they refer to as their ability to execute Direct Digital Manufacturing.

Free noted, “Direct digital manufacturing, or DDM, is taking additive manufacturing, also referred to as AM, to the next level. Our systems are almost entirely automated, from the time a user uploads a digital model, through production, and on to packaging and shipment. Direct digital manufacturing allows us to be incredibly efficient and produce parts, in large volumes, at prices competitive with traditional manufacturing methods.”

CloudDDM also points out that it primarily works with customers already familiar with additive technology and offer the most common materials to streamline its service offering. But, it is the combination of matching its customers’ needs with advanced technology, automation, and logistics that sets them apart.

Free likes to emphasize how the CloudDDM automated additive manufacturing cell technology they developed is only one piece to solving the puzzle. “Speed and scale were the starting point. Providing maximum responsiveness to our customers was the critical link in addressing the high costs and inefficiencies found in existing additive business models. By leveraging both UPS’ experience and expertise in logistics and the end-of-runway location near UPS Worldport hub, we are able to provide our customers with a complete solution”

While operating out of the UPS Supply Chain Solutions Campus gives a startup like CloudDDM unprecedented access and assistance from a global leader in logistics, there are benefits for UPS as well.

“We are excited to have CloudDDM as a resident on our UPS Supply Chain Solutions Campus,” said Mark Wallace, UPS President of Global Logistics and Distribution. “Locating at UPS Worldport hub allows CloudDDM to leverage our integrated network and end-of-runway location to get 3D printed parts in the hands of their customers as quickly as possible. As this technology continues to become more mainstream, UPS has the ability to scale the shipping and logistics solutions to meet the additive manufacturing services provided by CloudDDM.”

In addition to locating its operations on the UPS Supply Chain Solutions Campus, UPS has taken a minority stake in CloudDDM through the UPS Strategic Enterprise Fund. The UPS Strategic Enterprise Fund is a corporate venture capital fund that focuses on developing critical partnerships and acquiring knowledge that returns from its investments in information technology companies and emerging market-spaces.

As of launch, CloudDDM has completed Phase I of its installation on the UPS Supply Chain Solutions Campus and expansion is already underway. Additionally, plans are being made for additional operations to be established in Europe and Asia.

Free stated, “We are all in. The only way that additive manufacturing will become mainstream is to put the benefits of industrial scale additive manufacturing within reach of manufacturers, both large and small, worldwide.”

Related: 3D Printing Promises to Transform Manufacturing & Supply Chains

Article Topics

Fast Radius News & Resources

UPS & SAP Roll Out Plans for Full-Scale On-Demand 3D Printing Manufacturing Network Will Disruption Take a Bite Out of Logistics Jobs? 3D Printing Operation on UPS Supply Chain CampusLatest in Business

Ranking the Top 20 Women in Supply Chain TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process U.S. Manufacturing Gains Momentum After Another Strong Month More Business