3 Ways the IoT Will Transform Manufacturing Processes

The Internet of Things (IoT) promises to connect all sorts of stuff to the Internet, from fridges and thermostats to factory equipment and wind turbines. And the big data those things produce promise to deliver new insights and cost reductions across the entire business ecosystem.

But for most of us, the smart manufacturing future seems far off, if not far-fetched.

Surprisingly, it’s not.

Seeking the IoT for help isn’t like wishing upon a star. The IoT isn’t fantasy. It’s real, and it’s happening. In fact, 18% of industrial machine companies are already using it to some extent. For manufacturers, looking ahead to the IoT is a smart move that can inform the way you solve major problems today.

Here are 3 must-knows about the IoT’s “smart manufacturing” revolution:

1. You Will Take Back Control of Your Outsourcing.

Manufacturers outsource to reduce costs. It’s a trend that won’t let up anytime soon. But outsourcing has a downside—the loss of control. You’re handing off production to someone else, and you don’t know how they’ll handle it. Quality control, assurance of supply, and sustainability all become issues. But that’s changing.

The IoT will provide better transparency into your partners’ processes. Smart machines in smart factories will communicate their real-time statuses to a centralized hub that can verify production. Location and time-stamped data will provide better visibility and control, so that offloading your production doesn’t have to compromise accountability.

2. Volatile Demand Won’t Cripple Production.

Manufacturing today is tough because demand is capricious. Markets saturate. Geopolitical events disrupt commerce. Emerging regions develop. Companies are discovering they need to stay on their toes to eke out a profit. Gone are the days of simply creating a good product and selling it.

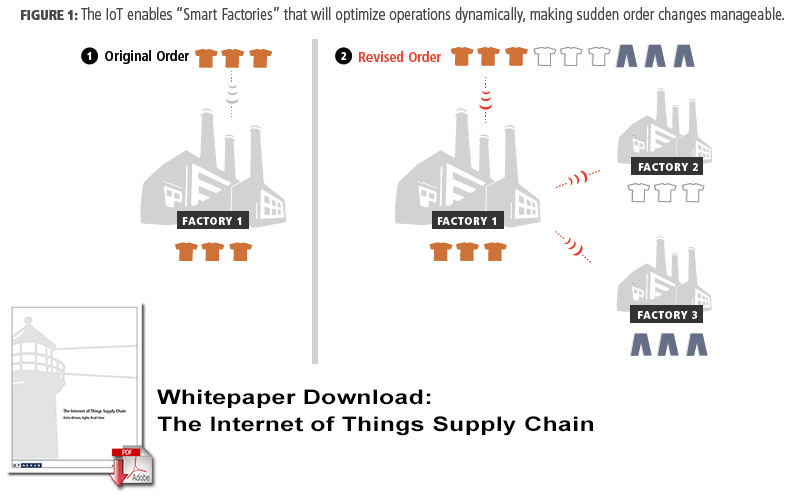

These days, process matters just as much as product. The IoT and smart manufacturing will enable rapid process adjustments to changing demand. How? Picture a sudden order change coming into a smart factory where machines are designed to talk to each other. The order comes in, the machines assess one another’s capacity and coordinate with machines in another location. They then optimize operations, and begin altering production all on their own, perhaps dividing the workload between factories on completely opposite sides of the globe.

3. Beyond Push and Pull, You’ll Be Able to Predict.

The old way of manufacturing was based on a push system. You’d produce a product based on your expectations of demand, and then push it out to various markets accordingly. Expectations like the best laid plans, often go awry. So the next step was to create a pull system, where demand and inventory stock triggered production up the supply chain. This is a good system, but it depends heavily on accurate data, and many companies find it difficult to execute without a centralized visibility platform.

The IoT will further incentivize moving toward a centralized visibility platform by taking push and pull a step further—it will use real-time data and analytics to predict demand, combining the best of planning and execution. Real-time data would feed into constantly improving models of demand, creating a production system that’s always in pulse with the markets.

Often, getting ready for adopting a new technology is painful. But in this case, it doesn’t have to be. Preparing your manufacturing supply chain to take advantage of the IoT means getting your centralized visibility platform in place to handle the IoT’s big data. There are already well-established ways to do just that.

Article Topics

GT Nexus News & Resources

The Current and Future State of Digital Supply Chain Transformation Infor Coleman AI Platform to ‘Rethink Supply Chain’ and Maximize Human Work Potential End-to-End Visibility: Handling the Demands of Retail Mastering Supply Chain Finance ERP Suppliers’ Changing Role New Logistics TMS Platform Sets Sights on SAP Amazon Selects Infor for Global Logistics Business More GT NexusLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology