10 Tips for Keeping Your Fleet on the Road and Improving Order & Fulfillment Operations

When your fleet’s not moving smoothly, your business isn't either.

As rising fuel costs, increasing competition and a growing freight capacity crunch put pressure on transportation managers to get more out of their fleets, there’s a renewed focus on reducing idle time.

This isn’t just about drivers leaving engines on while their tractor-trailers are parked at a rest stop. Let’s take the notion of idle time up 10,000 feet to consider why vehicles in a fleet might not be fully utilized for a number of reasons.

Like many fleet owners/managers, your number one focus is likely on delivering outstanding customer service. To do so, you may plan your fleet for peak capacity, so that you can respond when demand spikes. But, keeping your business rolling by keeping extra trucks on the sidelines isn’t always the best strategy. In fact, it can be costly, especially when you factor in maintenance, taxes, insurance and other expenses.

So, in an age where the “do-more-with-less” mantra is fundamental to success, how do you minimize idle time and get on the road to a more efficient fleet – whether it’s private, for-hire or dedicated? There are steps you can take right now to eliminate waste and unnecessary costs and get more out of your fleet.

10 tips for unlocking efficiency, eliminating waste and reducing fleet idle time

1. Run Lean

Need visibility into the efficiency of your drivers, routes, maintenance and loads? Want to make better use of capital assets? Take supply chain inefficiencies out of the equation by optimizing your assets, routes, service levels and operating costs? Consider a dedicated fleet that incorporates Lean practices to transform your inbound/outbound transportation network.

2. Put empty miles in the rear view mirror

Empty miles are one of the most expensive aspects of running a fleet. When you send a vehicle out to deliver goods and it comes back empty, there aren’t any revenues offsetting the cost of those empty miles. The key is to optimize assets, routes, service levels and costs to streamline your transportation network. That might mean partnering with a dedicated provider that can arrange revenue-generating backhaul opportunities to minimize empty miles.

3. Rightsize, rightsize, rightsize

If you have vehicles sitting on the sidelines, chances are your fleet is too large. Work with transportation experts to rightsize your fleet, driver workforce and use of common carriers. Adopt fuel strategies that consolidate carriers and loads.

4.Reduce wait times

One of the most common causes of fleet idle time is poor planning that leaves drivers waiting at a dock to load or unload a tractor-trailer. To reduce wait time, map out processes, detailing how material and information flows from production to customers. Look for ways to eliminate excess moving, handling and inventory and keep goods and processes flowing smoothly.

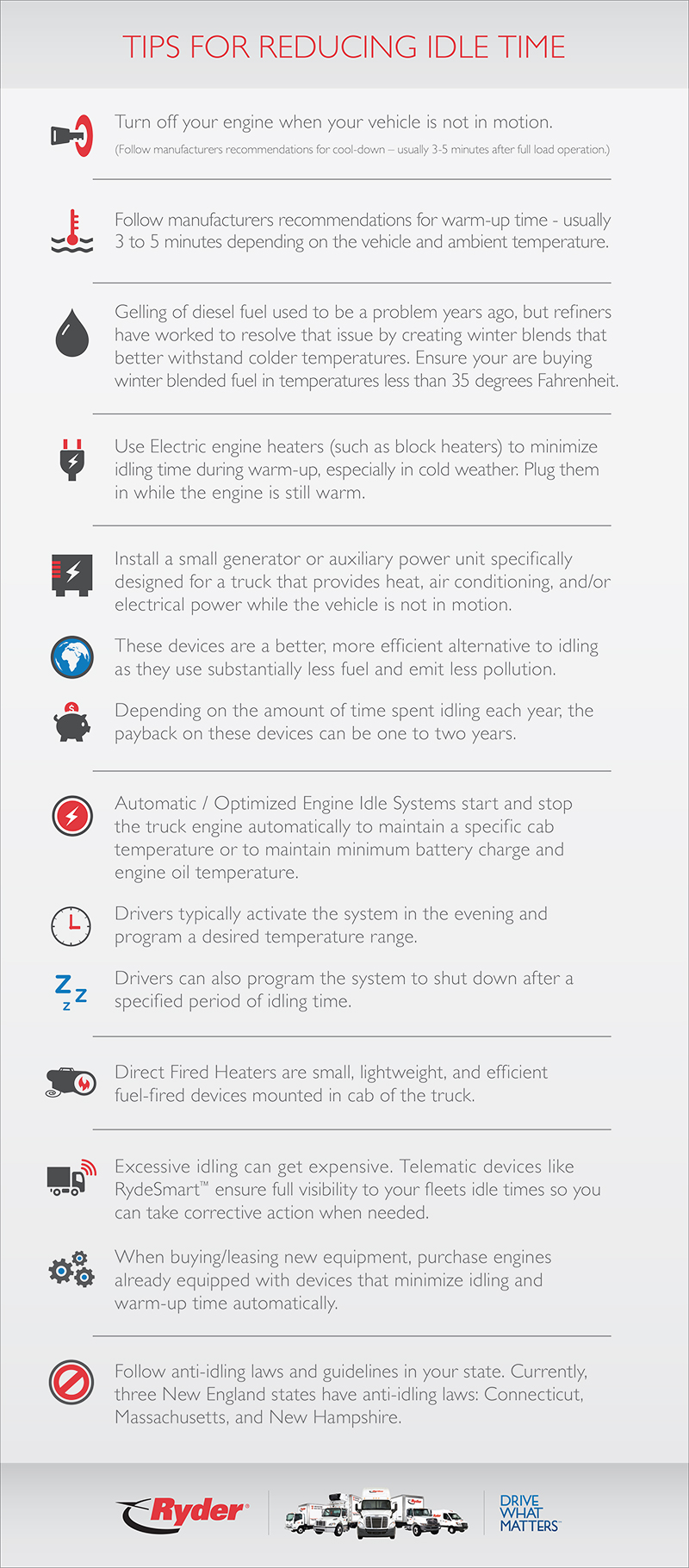

5.Sideline engine idle time

Ok, here it is. After labor, fuel is probably your biggest fleet expense. Why waste precious fuel – and dollars – at a roadside rest stop because your drivers leave the engine running? Filling up the tank of an average 18-wheeler costs upwards of $1000. By making a few modest adjustments in driver behaviors, you can save a great deal of money on fuel over the long haul.

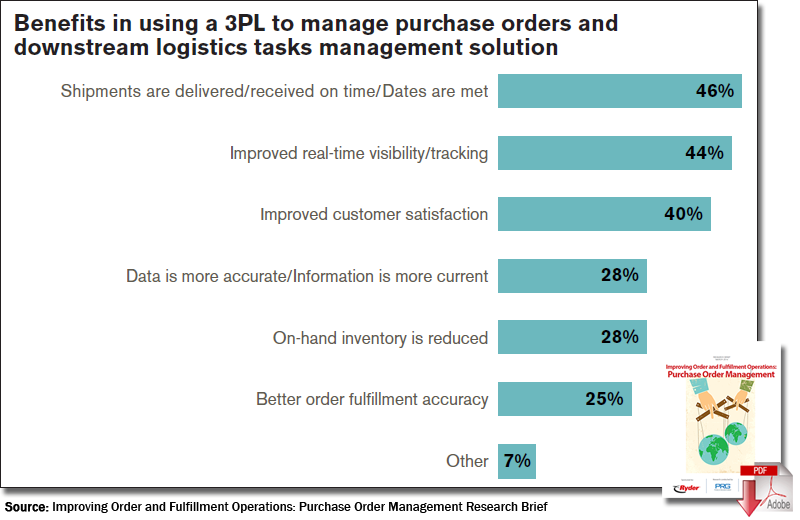

Improving Order and Fulfillment Operations: Purchase Order Management

In some cases, technology and the related analytics are helping companies get their arms around their key purchase order management issues. Using this information, organizations can gain visibility over open orders, order fill rates, order cycle times, order quantities (versus what’s actually been shipped), and supplier response time. Armed with this knowledge, companies can gain key insights into the strengths and weaknesses within their global supply chains, reduce operational costs, and increase sales.

By managing all facets of the purchasing process—including order acceptance, shipment creation, invoice consolidation, and document generation—purchase order management systems enable collaboration, improve real-time visibility, ensure order fulfillment accuracy, reduce cycle times, lower supply chain execution costs, and more effectively support compliance initiatives. In this brief we’ll examine the challenges that today’s organizations face when managing their global supply chains and look at the role that purchase order management plays in the smooth-running of such systems.

6. Maintain a state of perfect flow

When people, materials, equipment and processes flow smoothly, you’re better able to get quality products to customers when and where they want them. What’s more, eliminating unnecessary movements and delays results in shorter lead times and less fleet idle time.

7.Get connected

Advances in onboard navigation technology can help you make the most of your drivers and vehicles. With real-time data about vehicles, drivers, and traffic conditions, you can keep your drivers and trucks on route or ease them through traffic snarls to reach their destinations faster. Accident gumming up the works on one route? Divert the load to another to avoid delays.

8. Track driver behavior

Telematics doesn’t just tell you about vehicle locations, fuel usage and DOT log requirements. It also tracks idle time, so you know if drivers are leaving their engines on to keep the cab warm or cool (depending on the season) while they take a break to eat lunch.

9.Look at the big picture

With the latest on-board technology, you know what’s happening across your fleet. By aggregating data across the fleet, you can balance loads, boost driver productivity, and fine-tune trade cycles.

10. Keep small problems from turning into big ones

Regulator preventive maintenance and inspections (including at fuel stops) are essential to keeping your fleet on the road – and keeping small issues from turning into big ones. Preventive maintenance includes everything from vehicle inspection, lubrication and adjustment to cleaning, testing, repair and/or parts replacement.

Are you employing every weapon in your transportation arsenal to keep your fleet on the road? Is your dedicated provider up to date on the route, driver and load optimization strategies? Idle time reduction steps?

Source: Ryder Exchange