Five Key Considerations for Thermal versus Direct Transfer Printing

This easy to understand white paper describes the differences between thermal transfer and direct thermal printing, and charts the strengths and weaknesses of both technologies.

Direct thermal label printing has traditionally been a niche technology used across several narrow vertical markets including meat, poultry and dairy.

However, developments in thermal paper technology have resulted in a broader range of products that are now suitable for use in many applications across nearly any vertical market.

The result has been increased interest in direct thermal as the technology choice for new or upgraded applications.

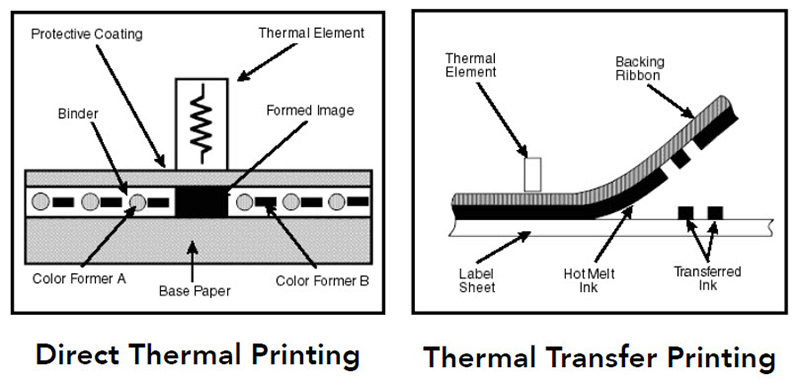

First, what’s the basic difference between direct thermal printing and thermal transfer printing? In simplest terms, thermal transfer printing utilizes a thermal ribbon and direct thermal printing does not.

Thermal transfer involves the thermal printhead elements (dots) heating the backside of a thermal transfer ribbon to melt and transfer the compounds on the front side of the ribbon to the label material, thus creating the printed image.

Direct thermal printing requires a heat sensitive label material. The printhead elements come into direct contact with the heat sensitive material where the heat from the elements causes a color change in the material to create the printed image.

Of course, there is a great deal of science and technology that makes both technologies work effectively, but that detail is well beyond the scope of this paper.

Knowing the difference between thermal transfer printing and direct thermal printing is only the first step in evaluating the two alternative technologies for use in a company’s label printing application. The following considerations, while not an exhaustive list, account for the key areas of review during the technology evaluation stage.

What’s Related

Favorites