One-Half of Manufacturers Globally to Adopt Wearable Technology by 2022

Majority of surveyed manufacturers to embrace Industrial Internet of Things (IIoT) to improve quality and operational visibility.

Zebra Technologies Corporation, revealed the results of the Zebra’s 2017 Manufacturing Vision Study, a body of research analyzing the emerging trends shaping the future of industrial manufacturing.

The global study revealed manufacturers are adopting the IIoT to enhance visibility and improve quality.

Driven by globalization, intensifying competition and rising customer demand for more options and higher quality products, a connected plant floor has become a necessity.

Zebra’s survey shows the number of organizations achieving a fully connected factory is expected to rise dramatically over the next five years.

KEY SURVEY FINDINGS

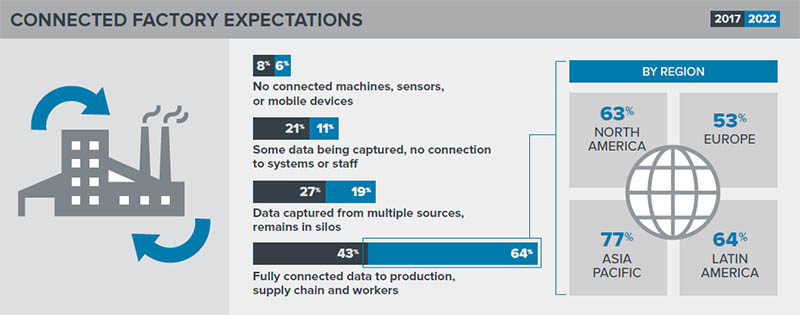

- Manufacturers will continue to adopt Industry 4.0 and the smart factory. Workers will use a combination of radio frequency identification (RFID), wearables, automated systems and other emerging technologies to monitor the physical processes of the plant and enable companies to make decentralized decisions. By 2022, 64 percent of manufacturers expect to be fully connected compared to just 43 percent today.

- One-half of manufacturers plan to adopt wearable technologies by 2022. And 55 percent of current wearable users expect to expand their level of usage in the next five years.

- Manual processes are expected to dramatically decline. Today, 62 percent use pen and paper to track vital manufacturing steps; this is expected to drop to one in five by 2022. The use of pen and paper to track work in progress (WIP) is highly inefficient and susceptible to error.

- Executives across all regions cited achieving quality assurance as their top priority over the next five years. Forward-looking manufacturers are embracing a quality-minded philosophy to drive growth, throughput and profitability. By 2022, only 34 percent expect to rate this as a top concern – signaling that improvements made by both suppliers and manufacturers will ultimately improve the quality of finished goods.

- Manufacturers stated investments in visibility will support growth across their operation. Sixty-three percent cited tracking as a core focus with a blend of technology (i.e. barcode scanning, RFID and real-time location systems [RTLS]) expected to be deployed to achieve the desired visibility.

- Fifty-one percent of companies are planning to expand the use of voice technology in the next five years. The most dramatic growth for voice technology will be in the largest companies (>$1 Billion) with a reported use growing to 55 percent by 2022.

Jeff Schmitz, Senior Vice President and Chief Marketing Officer, Zebra

“Manufacturers are entering a new era in which producing high-quality products is paramount to retaining and acquiring customers as well as capturing significant cost savings that impact the bottom line.

The results of Zebra’s 2017 Manufacturing Vision Study prove that IIoT has crossed the chasm, and savvy manufacturers are investing aggressively in technologies that will create a smarter, more connected plant floor to achieve greater operational visibility and enhance quality.”

REGIONAL FINDINGS

- On-demand, cloud, and Software as a Service (SaaS) solutions for Manufacturing Execution Systems (MES) are expected to grow rapidly with 58 percent of North American respondents expecting to use these services in 2022.

- By 2022, 54 percent of surveyed European manufacturers plan to use RTLS to collect critical data about assets including location, stage and condition.

- More than one-half (51 percent) of surveyed Latin American manufacturers and 48 percent of Asia-Pacific manufacturers plan to use RFID to optimize production WIP by 2022.

- Almost six-in-ten (58 percent) Latin American manufacturing executives cite improving quality assurance as their top priority over the next five years.

- Companies are focusing less on keeping materials on-hand and depending more on suppliers to provide goods on-demand. In five years, Just in Time (JIT) shipments will have the highest use in Latin America (42 percent) and Asia Pacific (40 percent).

SURVEY BACKGROUND AND METHODOLOGY

- 1,100 North American, Latin American, European and Asia Pacific decision makers who authorize or influence the purchase of relevant manufacturing technologies were interviewed by Peerless Insights.

- The online survey was fielded in the first quarter of 2017 across a wide range of segments, including automotive, high tech, food and beverage, tobacco and pharmaceuticals.

Article Topics

Zebra Technologies News & Resources

Data Capture: Bar coding’s new companions Zebra Technologies introduces wearable computers Data Capture: Bar coding’s new friends Retail distribution closes in on the customer Enhance Your 3PL Operations in 2024 with the Latest Technology Solutions Automatic data capture (ADC): Accelerating the process Van Meter: Saving space while increasing throughput More Zebra TechnologiesLatest in Warehouse|DC

U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring The Harsh Reality for Amazon and Walmart Warehouse Workers Supply Chain Stability Index: “Tremendous Improvement” in 2023 AI Not a Priority for Retailers and CPG Companies More Warehouse|DC