Your Inventory Optimization Solution Could be Creating an Inaccurate Forecast

Inventory buffers can counteract the effects of inaccurate forecasts...but, are you setting wrong inventory targets because your inventory optimization solution doesn’t understand how bad the forecast really is?

Forecast error, quite simply, is the difference between forecasted demand and the order that actually came in.

A good inventory optimization solution uses the mismatch between forecasts and orders to come up with stocking levels.

If the forecast is often wrong by a lot, more inventory is needed to meet demands on time, and vice versa.

Less error (or a more accurate forecast) is always better – but, forecast error is a reality for supply chains, and getting it wrong only compounds the problem of an inaccurate forecast by making it more difficult to correctly stage inventory to deal with the uncertainty of demand.

The Relationship between Forecast Error and Lead Time

The time horizon of interest for determining ideal stocking levels is the lead time to replenish the product. Let’s take a look at how forecast error and lead time are related, and how some inventory optimization solutions get things right, while others get them wrong.

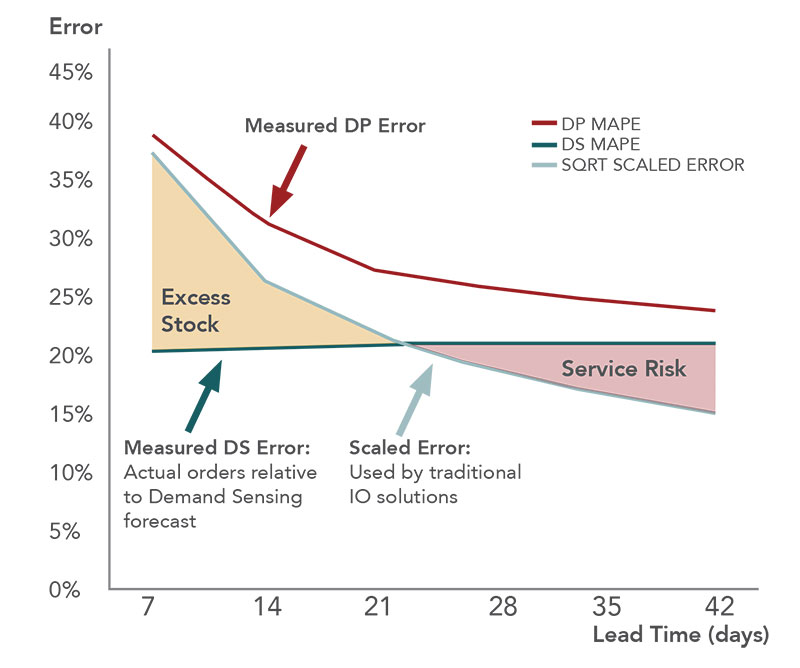

As Figure 1 shows, forecast error decreases with lead time. Intuitively, we understand that orders sometimes come in more than forecasted and sometimes less. So, total error relative to total demand goes down as lead time goes up, because daily under- and over-forecasting situations tend to cancel out.

Advanced Topic: What’s this talk of lead times going up or down – isn’t lead time for a product at a location, a given?

Well, two things to note:

1) In multi-echelon situations where stock at a parent location supports demands at a child location, the effective replenishment lead time at the child or forward location depends on stock at the parent location, and

2) even in a single-echelon situation, as we’ll see below, some inventory optimization solutions estimate error for a week, and then ‘scale’ or map it to the actual lead time of, say, 3 days or 12 days.

Measuring error over the actual lead time avoids this jump from 7 days to 3 or 12. Yet another problem that some inventory optimization solutions introduce is starting this 1 week of estimation after a ‘lag’ of 2 or 3 weeks – don’t ask us why they do this, but this is a bad idea. It is best to measure error directly over the actual lead time.

The red line at the top is the typical error measured by comparing actual orders with the forecast generated by a traditional Demand Planning engine. In our observations working with large datasets, we have seen this downward trend of error with lead time, over and over again.

The blue line represents error estimated and scaled by a commercially available inventory optimization solution. The computed (not measured) error is reduced as the square-root of lead time. The assumption behind applying this formula is that error in one period is unrelated to the error in the next.

This independence assumption does not hold very well in real-life situations – sometimes customers stay indoors due to poor weather and ‘pent-up’ demand rolls forward to the next period. Sometimes customers fear a shortage and place their orders early. So, even though error often cancels out, we can’t say that it is fully independent across time buckets.

The area between the two lines shows the risk of being understocked due to the underestimation of forecast error. It is one of the main reasons some inventory optimization solutions have not been effective.

To reiterate, find an inventory optimization solution that measures forecast error over the actual lead time instead of working with estimated error that is scaled to lead time. If that scaled error starts with an estimate of ‘lagged’ error, don’t look back. You deserve better.

When You Improve Forecast Accuracy, Let Your Inventory Optimization Solution Know

Figure 2 shows error measured by comparing actual orders to E2open’s Demand Sensing forecast. The first thing to note is that forecast error is significantly reduced relative to the error of the traditional Demand Planning forecast, especially in the short term. But, that is the subject of another blog.

To get back to the topic of inventory optimization solutions, if you have the benefit of the Demand Sensing forecast, but your inventory optimization solution is working with an erroneous estimate of error, you would be significantly over-stocked where lead times are short, and, as before, be significantly understocked where lead times are long.

All things being equal, this means that the non-Demand Sensing enabled optimizer would favor inventory distributions with longer lead times overall, relative to a Demand Sensing enabled optimizer – resulting in more stock at forward locations, with less inventory-pooling than, say, E2open’s Multi-Enterprise Inventory Optimization (MEIO) solution.

It’s clear that directly measuring forecast error over the actual lead time is better than estimating and manipulating it, and working with a better forecast is best for a truly optimized inventory plan.

Related White Papers

Demand Sensing Solution Utilizes real-time data to Predict Near-Term Demand

Companies that use Demand Sensing receive the best forecast for response and execution time horizons. Download Now!

Multi-Echelon Inventory Optimization

E2open's Multi-Echelon Inventory Optimization solution provides accurate modeling of current conditions, optimal inventory targets, fast run-times and rapid analyses, enabling organizations to reduce inventory while protecting or increasing service levels and customer satisfaction. Download Now!

Article Topics

E2open News & Resources

E2open President and CEO Farlekas Provides Logistics Trends and Themes Overview E2open Transportation Management Solution to Simplify Your Logistics Supply Chain Disruptions and the Next Normal for Logistics in 2023 Outsourced Quality and Sustainable Manufacturing in a World of Disruption Mitigating Supply Chain Disruption in the Wake of Severe Weather and Disasters Uber Freight & E2open to Provide Real-time Transportation Rate and Capacity Options Tracking and Reducing Transportation Emissions More E2openLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain