Why Outsourcing Your Supply Chain Makes The Big Data Problem Worse

The reason why there has been so little progress on the visibility front is that today’s supply chains are too sprawling, too outsourced, and too complex for traditionally architected systems to handle.

We’ve already discussed how Big Data and Visibility are the two biggest buzzwords in supply chain.

One question you may be wondering is, are these trends related?

Yes. Simply put, to obtain end-to-end visibility you need to solve a number of big data problems.

The reason why there has been so little progress on the visibility front is that today’s supply chains are too sprawling, too outsourced, and too complex for traditionally architected systems to handle.

Companies have abandoned vertical integration, instead outsourcing a large majority of the supply chain functions that they once managed in-house.

The result is that supply chains have become incredibly complex global webs of trading partners scattered all over the world, each focusing on a narrow slice of the fulfillment or manufacturing process. They are filled with 1000s of suppliers, SKUs, and components.

Introducing The Big Visibility Road Map

Reaching the holy grail of big visibility will not be easy. It requires a wide range of data from across the internal supply chain, the trading partner network, and from macroecomomic conditions.

Current supply chain analytics tools are nowhere close to delivering these kinds of advanced analytics. They struggle with capturing, housing, and analyzing data, much less recognizing demand and supply patterns.

Even more discouraging, Gartner predicted that many of the analytics-based supply chain decision support tools will likely become obsolete due to their inability to deal with big data, conduct analysis within the required time cycle for the decision, and automate decision making.

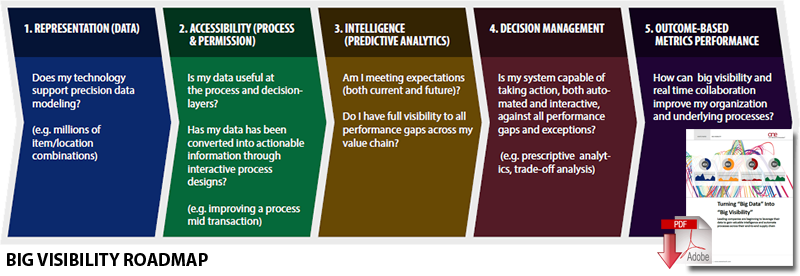

So how can companies achieve big visibility? What follows is a 5 stage maturity model that organizations can use as a roadmap. Each stage of maturity offers its own unique challenges (and benefits if achieved).

The five stages (illustrated above) are representation, accessibility, intelligence, decision management, and outcome-based performance.

Executives understand that their traditional enterprise management systems are not designed to manage activity beyond the four walls of their enterprise, and are certainly not equipped to deal with the big data problem.

As supply chains become more tangled, with a greater number of far flung suppliers, managers are faced with risks that can crop up in dozens of countries.

No wonder a recent Deloitte survey of 600 executives at manufacturing and retail companies found that 63% were highly concerned about risks within the extended supply chain comprising vendors and customers, ranking it among their top-two concerns.

In response, companies that have long used complex data sets to plan manufacturing to meet customer demand are now looking to combine data from external sources to better predict future risks.

The problem is, if a single manufacturer alone can house 20 petabytes of data (as we already learned), how much more data must the rest of the supply chain contain?

Article Topics

One Network Enterprises News & Resources

Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Companies Need to Develop New Innovative Approaches to Supply Chain Design How to Improve Cost of Goods Sold Horizontally Across the Supply Chain How the Global Pandemic Accelerated Supply Chain Visibility, Digitalization, and Automation AI and Data, the Future of Supply Chain Management AI and Supply Chain Problem Solving More One Network EnterprisesLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology