What’s Missing in Your Total Landed Cost

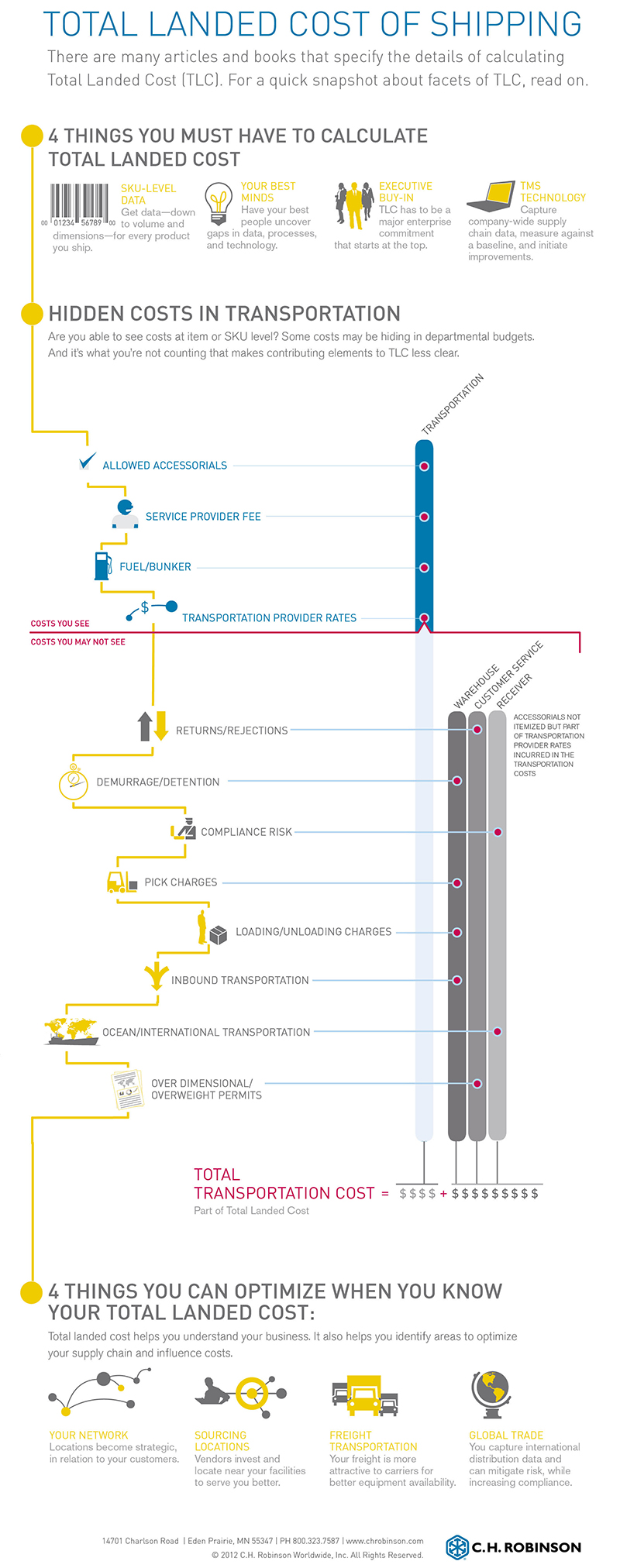

Unless you hunt down and include all hidden costs in your TLC calculations, you’re basing supply chain decisions on incomplete data - the key is to bring those missing costs out in the open.

From what we’ve seen, it is rare that a company knows their true total landed cost (TLC) for each item they produce and deliver.

There’s a reason for this. For most companies, there are many costs in hiding. And unless you hunt down and include those hidden costs in your TLC calculations, you’re basing supply chain decisions on incomplete data.

So if it’s the norm for companies to not measure some of the elements that contribute to total landed costs, how do you become the exception?

The key is to bring those missing costs out in the open.

Start with the baseline. Capture SKU details for every product you have, to the most granular level you can. Develop robust cube, dimension, and weight data for all of your products and keep it up to date. That will bring deeper insights into your total landed cost. Yes, capturing SKU-level data can be labor intensive, but EDI helps automate this, and lends a great degree of data accuracy.

What can you do with dimensional data? Most companies generically assign lots per SKU to a truckload, container, etc. But when you have dimensional information on each product that you ship, along with its packaging, you can build better pallets. You can more accurately optimize and consolidate those into full shipments.

What’s more, you get data back so you can make more accurate allocations. Say a truck has 15 different SKUs on it. To what extent did SKU #1—toothpaste, let’s say—fill up that truck or ocean container? If you have good dimension information, you will know that it consumed one-fifth of the equipment’s space, but represented 25% of the weight on the truck. Knowing the cost to deliver, you can attribute total landed cost based on the weight or cube that the SKU occupied.

You can also analyze what a specific SKU is costing you. Is one SKU more frequently damaged? Is it more expensive to deliver? Do you have receivers who have a particular problem with that SKU at delivery, and does that present a cost or accessorial reduction opportunity?

Transportation accessorials can represent another type of gap in your total landed cost calculation. These are costs for supplementary services that are provided in connection with transportation; they are not always included in the freight charge.

Here’s what can happen. Say that a Transportation Department has decided that it will pay a maximum of $100 for detention, and that Transportation pays the carrier’s invoice. And in this company, the Shipping Department controls the loading process. Perhaps Shipping loads inefficiently, so the driver is regularly detained. And in the end, the carrier’s cost for that detention is usually $150. Since the carrier can’t recoup enough of their costs to make a profit, they could build the extra $50 into their line haul rate.

In the example above, the shipper still pays $150 for detention, but they aren’t measuring the full cost. Shipping certainly isn’t tracking it, because accessorials don’t directly affect their compensation and goals. And yet, the costs are significant to the company overall.

Accurate identification of all costs affords visibility to your total costs, and allows you to understand and influence total cost elements. Without it, you have missing links in your TLC calculation.

What you really want are meaningful metrics. When you only measure things like cost per mile or cost per pound, the closest you can get to total landed costs is to say, “This is my true cost to deliver nationwide.” But when you have deeper metrics, you can say, “This is my true cost to deliver this SKU to this customer.”

And that’s where it gets really powerful.

When you have SKU-level data, you can determine whether you are charging customers appropriately for their products. When you can accurately identify cost drivers at the item level, you have greater visibility to your total transportation costs—just one component of Total Landed Cost. You can enhance budgeting and auditing capabilities, support cash flow projections, and better understand cost variances.

With visibility, you can understand the true expense and influence total cost elements. You gain optimization opportunities, and better analytics on what a specific SKU is costing you.

Additionally, such insight can lead to changes in the price of your product. It’s quite possible you have a highly efficient product in terms of total delivered cost, which is mixed in with other products. But that information never makes it back to your marketing and sales team because you didn’t have a good way to measure it.

But if you can gather a broad universe of information and gaps, and pull SKU-level data and analyze it—you can interpret the findings and arrive at the true TLC. You have the whole picture. You know the cost of returns, damages, customs, and imports by SKU. You can make market-based decisions on that product. It’s not mixed in with other things that could be distorting your analysis.

You don’t have to let hidden transportation costs affect your TLC—if you know what to measure and have the technology to do it.

Related: Can Supply Chain Leaders Take a Lesson from Sabermetrics?