What are Supply Chain Professionals Using to Make Network Decisions?

Supply chain networks are becoming increasingly complex, which means it's now critical to have the right network design tools available.

Part I in our series on assessing your network design’s maturity

How does your network design compare to others? We recently created a quiz to help supply chain professionals answer this question.

Our goal was to help you identify potential improvement opportunities by answering a few questions and get a temperature check on the current landscape of network design solutions.

We had quiz takers from 23 countries and across industries – from chemicals to manufacturing, metals, telecom, cosmetics, consumer goods, transportation and food. It’s great to see the enthusiasm for this interactive tool.

Our findings show that most respondents rely on a combination of spreadsheets (nearly 60%), gut feel (15%) and previous experience (46%) to make supply chain network decisions.

Only about 22% use network design software and 18% use network design software with embedded analytics among this group.

More than half of the professionals assessed indicated that they didn’t use some form of advanced analytics to support their network design process. None of the respondents share data across multiple applications to manage inventory, network design and S&OP in an integrated way.

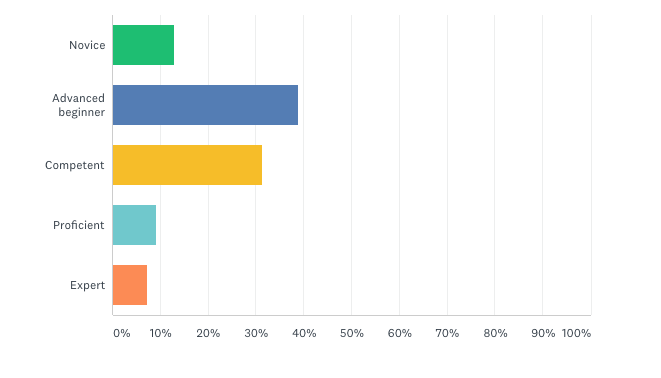

When asked to assess their maturity level in using network design technologies, most professionals stated that they considered themselves “advanced beginners” (nearly 40%), followed by “competent” (32%), “novice” (12%), and “proficient” at 8%.

It’s time to kick the spreadsheet habit

These quiz responses are fairly consistent with a 2017 survey by Lora Cecere’s Supply Chain Insights, which revealed that 65% of companies use spreadsheets for network design. Spreadsheets are inexpensive and familiar. People often stick to using them because they think they can’t afford a more advanced solution. Some also think the solutions available in the market are too difficult to use or too expensive.

The truth is, companies that use spreadsheets for network design are leaving major opportunities on the table. The more complex the network, the harder it is to make spreadsheets work. Spreadsheets are also known for being error-prone. In fact, as Market Watch reports, close to 90% of spreadsheet documents contain errors.

They don’t support robust optimization and they are unsustainable. Managing data across multiple spreadsheets quickly becomes unmanageable. If the person who initially created the spreadsheet leaves the company, it’s often harder for other users to understand the built-in logic as well.

It’s time for companies to kick their spreadsheet habit. Lower infrastructure costs and advances in cloud computing have made supply chain optimization technology a lot more accessible. Care should be exercised though, because the same reasons that have made the technology more accessible should’ve made it more affordable.

But unfortunately, that’s not always the case. Find the right partner to work with that can help your team make a big step forward and build this competency. The benefits can be considerable. Your team can reduce time spent on low value work and spend more time driving impact.

How advanced is your supply chain network design? Take our quiz to find out

Today’s most profitable companies have built their success on an effective and responsive supply chain network. But maintaining this is easier said than done.

Supply chain networks are becoming increasingly complex, serving multiple SKUs in hundreds if not thousands of locations. Building agility and resilience into your network is more important than ever, with trade disputes and natural disasters posing a constant threat. Achieving this can be difficult if your technology is not flexible enough. Too often, firefighting becomes the norm.

We’ve developed a quiz to help supply chain professionals find out how their network design stacks up against others. The quiz is also a handy resource to identify improvement areas.

For instance, did you know that while most companies use spreadsheets for network design, close to 90% of all spreadsheets contain errors? It may be time to revisit your tooling. Take the quiz below to find out how you score and how you can improve!

Related White Paper

What Are Companies Looking For in Network Design Technologies?

The purpose of this study is to understand the value proposition of supply chain network design technologies, including user satisfaction and key benefits and barriers to using these technologies. Download Now!

Article Topics

AIMMS News & Resources

The Post-Pandemic Warehouse & Distribution Center Workplace Assessing Supply Chain Planning: Ready for Today’s Challenges? Supply Chain Professionals Say Planning Process is “Somewhat Effective” Regardless of Technology Spending Too Much Time on Data Crunching and Not Enough on Resilient Planning Decisions Supply Chain Planning, Optimized | 3 AIMMS Case Studies Organizations are Betting on New Technologies to Improve Demand Forecasting Accuracy How is Demand Forecasting Changing? More AIMMSLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain