Uber like Logistics Innovation at West Coast Ports

West Coast Ports terminals seek ways to speed up after labor strife; an Uber-style app developed by Cargomatic should help.

Now that the West Coast ports are back in operation after a tentative labor contract resolution, experts are projecting that it could take six months to eliminate the current cargo backlog.

I will take the “under” and bet that this happens faster, because creativity always surges and resistance to change moderates when there is a crisis with a strong economic driving force.

It turns out that the West Coast port slowdown had been building for some time, as described in The Wall Street Journal article (“Ports Get Creative as Cargo Piles Up”). According to Gene Seroka, executive director at the Port of Los Angeles, as quoted by the WSJ, “larger container vessels have contributed to much of the congestion. More cargo is arriving now than terminals were accustomed to dealing with…and it is less organized on the ships.” (My previous blog post “ReLearning the Value of Logistics Agility” addressed this impact of larger container ships.) One terminal manager indicated that he “has never had so many executives schedule visits to his facilities as occurred over the past nine months”.

One global chemical company recently shared with Gartner that it identified the West Coast port situation as a risk one full year in advance, taking actions to mitigate its impact and suffering virtually no consequences from the eventual shutdown.

“Suddenly, the supply chain gets out of kilter. There’s a call for innovation and creative ideas”, according to Mr. Seroka. Innovation that requires change is usually met with resistance, particularly in operating environments with strong union influence. However, the ‘drawn out labor negotiations…exacerbated the issue’. It may have ultimately provided the catalyst that was needed to reduce the natural resistance to change that every operating environment fosters. In a sense, things needed to get worse before they could get better.

After trying several changes, including the requirement of pick-up appointments which impacted truck drivers by limiting the number of loads they could haul in a day, the terminals have identified an operating mode called “free flow” that removes (rather than imposes) constraints for truck drivers. “Free flow” requires a process change from tradition, in which truck drivers arrive at the port with orders to pick up a specific container. Inefficient, wasted motion ensues as the container is fished out of a large pile by moving multiple containers around.

The difference with “free flow” is that wasted container movement and waiting delays are reduced by selecting a container for loading that takes into account its location on the dock. “Many of the mega-retailers (refer to ‘free flow” as) peel-off operations, (which allow) longshore crane operators (to) stack (containers) together and load them on to the retailer’s trucks as they arrive.” According to the WSJ article, “Last week, the Port of Los Angeles launched a similar system at four marine terminals, (allowing) as many as 600 containers a day to be moved off the docks as soon as they are unloaded from ships”.

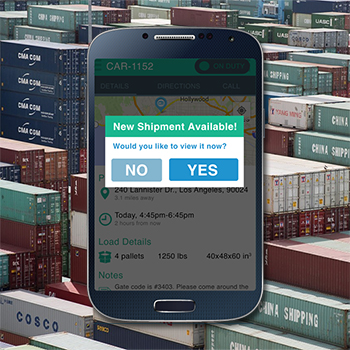

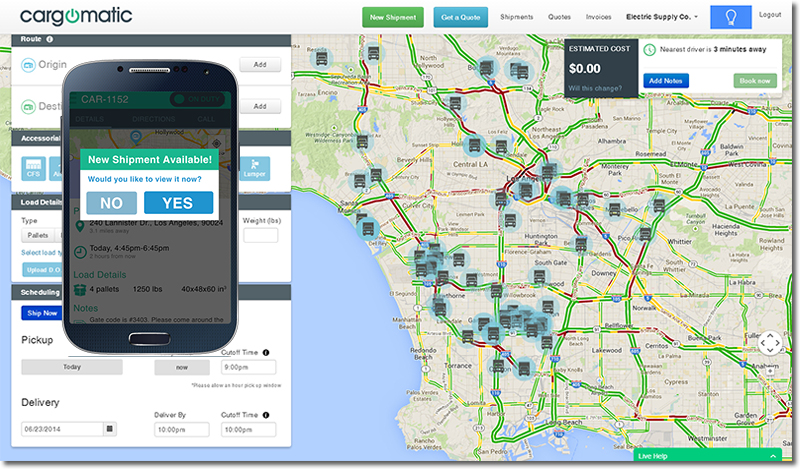

Technology has played a role in extending this concept beyond large retailers. Cargomatic has developed a program enabled by a “new smartphone-based Uber-style app” to make ‘free flow’ possible for smaller retailers. “Drivers show up to the (terminal)…no appointment necessary…and are given the first container off the top of the ‘Cargomatic pile’ (which is) destined for any customer signed up for the program. The driver logs the pickup in the (Cargomatic) app, which provides instructions on where to take the container”.

According to WSJ, “though small, the Cargomatic test proved to be a rare instance where the port’s productivity increased amid the labor strife. The average turn time for Cargomatic truck drivers was 35 minutes, roughly half the time it usually takes under the standard dig out process”.

Right now, all parties are focused on eliminating the backlog, so the environment for change is favorable and Cargomatics adoption on the West Coast seems isolated. It’s worth noting, though, that the system at four Los Angeles terminals mentioned above was implemented “minus the smartphone app”.

Source: Gartner Blog Network

Related:Uber’s Latest Experiment is Uber Cargo, a Logistics Service in Hong Kong

Article Topics

Cargomatic News & Resources

Cargomatic announces closing of $35 billion in Series B financing round Amazon Relay App Will Help Truck Drivers Get In and Out of Warehouses Faster Digital Freight Matching Services & Technologies 3 Tech Trends Shaping the Future of Global Logistics Putting the Ever Expanding Truckload Brokerage Business into Perspective Disintermediation to Hit Freight Brokerage Making the Leap to Uber Trucking More CargomaticLatest in Transportation

Baltimore Bridge Collapse: Impact on Freight Navigating Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Nissan Channels Tesla With Its Latest Manufacturing Process Why are Diesel Prices Climbing Back Over $4 a Gallon? Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws The Three Biggest Challenges Facing Shippers and Carriers in 2024 Supply Chain Stability Index: “Tremendous Improvement” in 2023 More Transportation