Top 5 Signs Your Supply Chain is Dysfunctional

Lack of upstream and downstream visibility and lack of control are reoccurring issues mainly because every supply chain uses the same basic technology - one designed to manage the activity behind the four walls of the enterprise.

As I discussed in my last post, “From Vertical to Virtual Integration”, over the past 25 years or so, supply chains have become far more complex and dispersed, and technology has struggled to keep up.

Lack of upstream and downstream visibility and lack of control are reoccurring complaints that I hear from companies across industries, including Retail, CPG, Automotive, Logistics, Hi-Tech, and the Military.

The fact is, every supply chain faces these problems because every supply chain uses the same basic technology—one designed to manage the activity behind the four walls of the enterprise.

So, with that said, here are four signs that your supply chain, regardless of industry, is dysfunctional:

1. You Are Not Focused On The End Customer

It doesn’t matter what role you play—whether a manufacturer, raw material supplier, co-packer, or 4PL—if the end customer does not buy the product, then you and no one else in the supply chain wins. CPG companies may measure themselves by DC service levels, but when was the last time you bought your groceries from a DC? Similarly, the military focuses on “wholesale and retail processes”, yet to the American soldier this is irrelevant; he/she really only cares about getting the supplies needed to stay alive. What matters is understanding the end customer in real time, and providing the right product, at the right time, at the right price.

2. You Are Running Multiple Forecasts

Standard practice for traditional supply chains is to run multiple forecasts (e.g. sales, manufacturing, suppliers). Multiple forecasts mean multiple demand/supply plans. This is bad! Each plan/forecast introduces another level of inaccuracy and complexity, and the result is higher than necessary inventory levels, more stock outs and errors, and lower service levels. You only need one forecast that starts with the consumer, that is updated in real time as demand and supply conditions change, and that computes downstream and order forecasts at each node. Never forecast what you can compute.

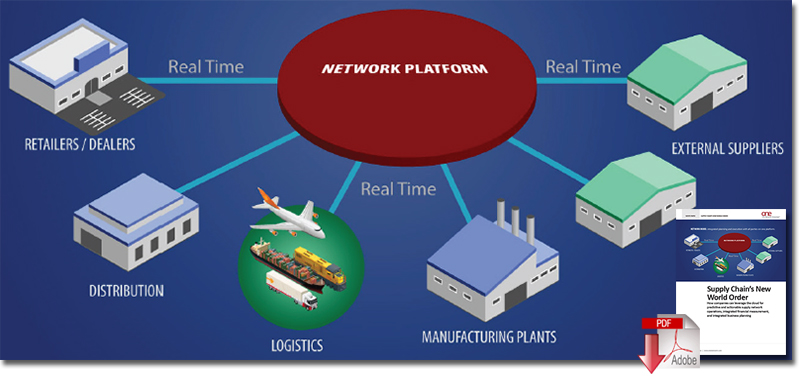

NETWORK MODEL integrated planning and execution with all parties on one platform

3. You Can’t See or Influence Supply in Real Time

Even if you can understand and respond to consumer demand, if the rest of the upstream supply chain community does not, then the wrong products are still being made for the wrong locations. Yes, every party should see the demand, but ideally they should also be able to see the supply plans and product in motion so that the demand/ supply match is clear to all.

4. You Have No Visibility or Response Capability to Issues Across The Global Supply Chain

Regardless of which party has custody of physical inventory or where the information resides, you can/should be able to view all shipments, inventory, and capacity limitations in real time and on demand. You can’t fix problems if you do not know they exist. But what good is the ability to sense a problem without the accompanying ability to respond? The newly visible information needs to be actionable.

5. You Don’t Incrementally Re-plan and Execute in Real Time Across The Community

Demand and supply conditions are constantly changing. As soon as you finish making a plan, it becomes inaccurate, and as time goes on, more inaccurate. You need the ability to adjust your plans in real time and execute those plans across your trading partners. You need to be able to do this incrementally, resolving only the problem areas in the plan so as not to create nervousness across the rest of the chain.

The fact is, if you’re only worried about managing what goes on in the four walls of your enterprise, the industry’s standard local tools can suffice. But in the modern outsourced supply chain, your success largely depends on what occurs outside of your four walls.

This is why most companies would benefit from connecting to a cloud-based many-to-many network. Doing so allows them to easily connect and coordinate with their trading partners no matter where they are physically located. They would then respond to supply and demand shifts in real time. They would optimize existing processes and discover new ways to capture value. They would be demand driven.

So how did you do? Is your supply chain dysfunctional?