Top 5 Hidden Costs of Dry Ice Shipping

Shippers who consider only the cost of dry ice, packaging and transportation perceive a low cost, but when recurring and non-recurring cradle-to-grave costs are considered, their perceptions change.

The combination of dry ice, Styrofoam® and overnight shipping worked miracles in the 1960s and transformed medicine on the battlefield and here at home.

Today, that combination remains a popular deep frozen shipping method, despite advanced technologies that improve reliability and cut costs.

Shippers who consider only the cost of dry ice, packaging and transportation perceive a low cost. But, when recurring and non-recurring cradle-to-grave costs are considered, their perceptions change.

The costs of materials, training, HAZMAT compliance, warehousing, tracking, regulatory issues, packaging disposal, ventilation for dry ice handling, insurance, labor, time and the potential loss of sample viability due to degradation can add $50, $150 or more to each shipment.

The top five expenses involve:

1. Specialty couriers and

2. Overnight Shipping

An important aspect of specialty couriers business includes managing the dry ice supply chain. Dry ice sublimates at -78.5ºC in one to two days and specimens must be monitored and re-iced. This not only causes potential temperature excursions but also requires that specimens be shipped using a specialty courier regardless of the lane. It also necessitates the fastest and in most cases, most expensive shipping methods.

By using more stable solution such as the CryoPort Express® Liquid Nitrogen Dry Vapor Shipper, specimens are maintained at a stable -150°C for 10 days.

This allows for freight forwarders such as FedEx and DHL, and standard carriers and shipping companies including ground transportation instead of always going overnight. It also opens up the shipment day possibilities to include the entire Monday- Friday week instead of only a four day week, as is common today, for fear that specimens will be compromised over a weekend. The combination of the two can have a transformative effect not only on the shipping costs but also how a clinical trial could be set up.

3. HAZMAT Requirements

Dry vapor liquid nitrogen is a non-hazardous, inert gas with no shipping restrictions. Dry ice, however, is classified by the International Air Transport Association (IATA) and the FAA as a dangerous good and accordingly requires Dangerous Goods documentation, special handling and ventilation. Additionally, only a certain amount at a time can go on planes. And, because airlines and couriers limit the quantity dry ice they carry, packages occasionally are bumped from flights. Dry ice is at temperature of -70 °C for one to two days, risking temperature excursions during these delivery delays.

4. Overhead

In addition to the hazard of shipping dry ice, there is the care, training and subsequent overhead of handling the dry ice on site.

Facilities must be equipped to store and handle the dry-ice and Styrofoam® material in well ventilated spaces. Staff must be properly equipped, trained and spend time packing and handling materials. Failure to train staff properly has resulted in significant fines by the FAA for companies regularly making dry ice shipments.

Staff at multiple locations must also coordinate ordering these materials, calling couriers, coordinating paperwork, confirming requirements and handling logistics. The overhead costs add up quickly and may not be realized in the cost per shipment.

5. Sustainability

Many companies are not only looking at their overhead and shipping costs, but also focused on a triple bottom line that includes sustainability. In addition to the hazards of dry ice, Styrofoam® is a major concern for companies looking at green initiatives.

Styrofoam® is non-biodegradable and considered a leading source of hazardous waste. In addition, this packaging used with dry ice typically is used once and thrown away. Cryoport, in contrast, cleans and reuses its aluminum dewars more than 100 times before recycling. Even the cardboard shipping boxes and trays contain 35 percent recycled content.

And nitrogen, unlike dry ice, is environmentally safe and non-hazardous. The hard costs of disposing of such materials in addition to the benefits of becoming a more eco-friendly company create a compelling story.

An Innovative Solution

Cryoport provides an innovative alternative to the hidden costs of dry-ice shipping.

In addition to solving the problems with sustainability, overhead costs, HAZMAT ratings, shipping and couriers, we’ve helped many companies be successful with cost-effective, reliable, safe and green solutions that make their companies stronger.

The improved sample integrity with dry vapor liquid nitrogen is an additional benefit we’ll explore in a future blog.

Related Link: Understanding of Refrigerants Used for Cold Chain Distribution

Temperature/Product Stability Requirements

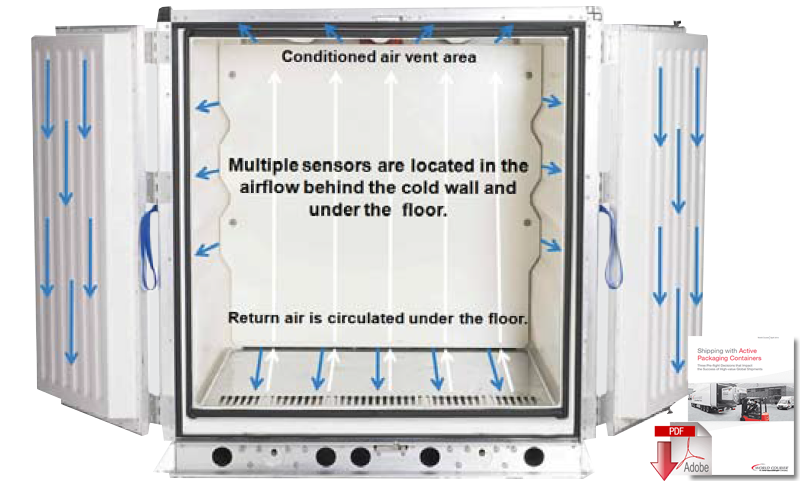

Assuming that the decision to use an active unit has been made, exactly which model is most appropriate?

There are currently three different technologies on the market: Cool Only, Heat/Cool using dry ice and Heat/Cool using a compressor.

The Cool Only units utilize dry ice to maintain lower internal temperatures in the -20°C to +20°C range.

Alternately Heat/Cool units − which are typically used to maintain temperatures in the 0°C to 30°C range − incorporate a heating/cooling unit within the system to maintain temperature while relying on a bunker of dry ice as the cooling medium. Other newer systems like Envirotainer’s RKN e1 and RAP e2 and the CSafe RKN utilize electric heating and compressor cooling (rather than dry ice) to maintain lower temperatures.

Because the stability of active pharmaceutical products or compounds can be negatively influenced by environmental conditions including temperature, air, humidity or light, the long-term reliability of the active container can provide added insurance in most contingencies. Data is available from the manufacturer attesting to unit performance.

As discussed above under payloads, the design of each active unit varies by manufacturer and accommodates a slightly different temperature range. Once again, an experienced logistics provider can provide guidance on the most appropriate choice of unit based on the shipper’s temperature requirements.

Source: World Courier

Download the White Paper: Shipping with Active Packaging Containers