Tiffany & Co.‘s New Chief Sustainability Officer on Polishing the Jewelry Supply Chain

Tiffany & Co. has been at the vanguard of efforts to weed out jewelry supply chain abuses by focusing on the traceability of raw materials, participating in human rights advocacy efforts and supporting stricter industry-wide standards.

Anisa Kamadoli Costa is Chairman and President of The Tiffany & Co. Foundation and Chief Sustainability Officer at Tiffany & Co.

She is no stranger to the inner workings of the luxury jewelry business - including notorious dark spots for the industry, such as human rights abuses and environmentally reckless mining operations.

As the longtime president and chairman of the foundation arm for one of the world’s most famous jewelers, Tiffany & Co., Kamadoli Costa is already well acquainted with efforts to improve transparency and standards for sourcing precious minerals.

Earlier this spring, however, Kamadoli Costa also was tapped to fill a newly created sustainability leadership role within the company. In April, she added chief sustainability officer of Tiffany & Co. to her ongoing Tiffany & Co. Foundation duties during a period of renewed focus on increasing accountability for global mining operations.

Tiffany has been at the vanguard of efforts to weed out jewelry supply chain abuses by focusing on the traceability of raw materials (Traceability in Global Supply Chains PDF), participating in human rights advocacy efforts and supporting stricter industry-wide standards.

Now, Kamadoli Costa, with renewed backing from the company’s C suite, is looking to elevate those efforts beyond previous self-policing measures in the jewelry industry that - like many industry certification efforts related to sustainability - have come under fire for lacking accountability.

Tiffany seeks to change that by refining its own long-term sourcing strategy and backing a much broader Initiative for Responsible Mining Assurance (IRMA), which will be piloting a new set of draft standards this year. The approach is outlined in the company’s new sustainability report.

“We’re at the point where we need to think beyond our own supply chains,” Kamadoli Costa told GreenBiz in an interview. “To me these are really basic, fundamental issues. Of course this should not be happening.”

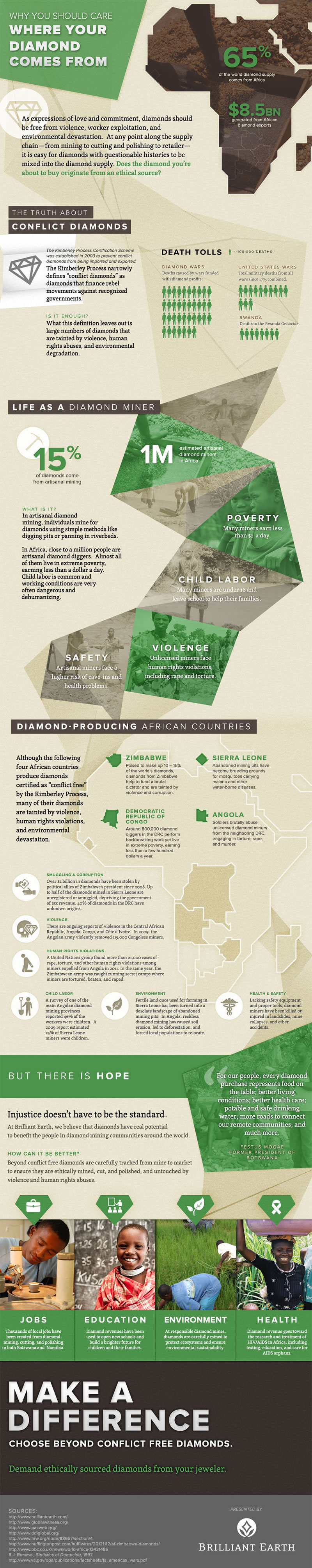

The phrase “blood diamond” first made its way into the mainstream after the 2006 Hollywood depiction of how warlords in the West African nation of Sierra Leone profited from exploiting residents forced into mining. Sales of the jewels, smuggled out of the country and distributed primarily in Western markets, helped fuel a civil war that killed 50,000 people during the 1990s.

As recently as this spring, however, Tiffany joined a chorus of critics calling for charges to be dropped against Angolan journalist Rafael Marques, who was prosecuted after writing extensively about torture and murders perpetrated by military officials profiting from the diamond trade. The abuses in Angola detailed by Marques, such as soldiers burying 45 miners alive in 2009, were part of a system of forced labor.

These recurring human rights scandals also often overshadow other social and environmental ills present in the diamond and metal supply chains, such as day-to-day wage theft, air and water contamination, dumping of toxic waste and disruption of sensitive ecosystems.

The question, as is the case in other industries with supply chains heavily reliant on raw materials and labor in far-away countries - such as the garment business or consumer electronics companies - is how to gain better visibility and begin improving conditions on the ground.

Related Read: Have Supply Chains Changed Since Rana Plaza?

“There’s so many different certifications out there,” Kamadoli Costa said. “We think that it would be beneficial for there to be a really high bar.”

Digging Into the Supply Chain

Given the fragmented nature of the global jewelry business, with raw materials being purchased and transformed into high-priced pieces by small artisanal jewelers and corporate retailers alike, tracing the path of an individual diamond or precious metal to its mine of origin can be difficult.

Part of that is due to middle men, such as smelters or other brokers operating in areas vulnerable to abuses.

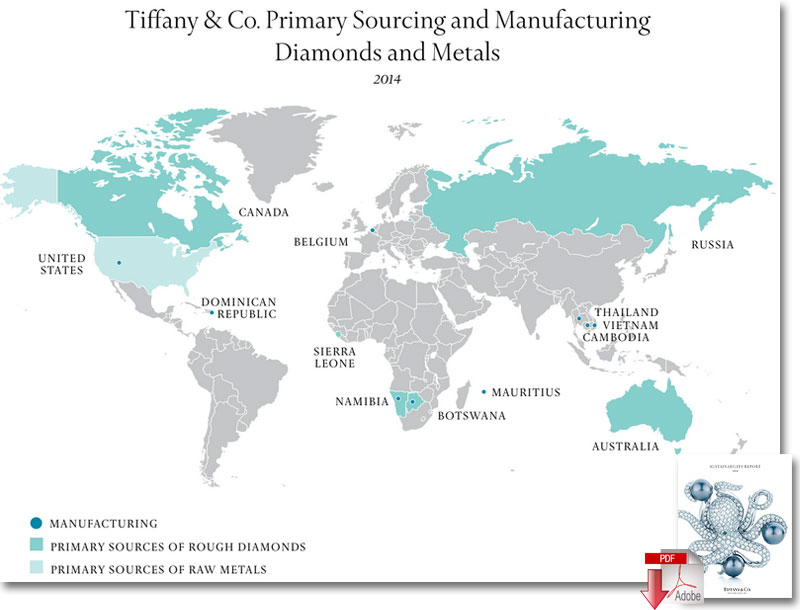

To combat those dynamics, Tiffany makes more than 50 percent of its jewelry at company-owned manufacturing facilities. Although the company does not own mines, most of the diamonds used in Tiffany pieces are purchased directly from mines in Australia, Botswana, Canada, Namibia, Russia and Sierra Leone, according to the company’s new sustainability report.

Tiffany & Co. buys the balance of its diamonds, gold, silver and other materials from suppliers who have achieved third-party verification through the Kimberly Process - a joint effort that grew out of the war in Sierra Leone and now unites governments, businesses and NGOs looking to “stem the flow of conflict diamonds.”

“We’re lucky because we are large. We have a well-known, respected brand,” Kamadoli Costa said. “We’re able to purchase in quantities and make positive demands that can be carried through.”

The company’s new sustainability report also lays out a range of internal strategic responsible mining goals, such as curbing contamination and waste, establishing clear labor standards and responding to local input on proposed mine development and expansion.

But the overarching goal is to improve industry practices through “leadership and participation” with the new standardization effort, IRMA. Although it’s still relatively early in the process, IRMA will have to overcome past criticism of the jewelry industry’s own enforcement efforts.

One critical take on insufficient industry action to date, a report by a coalition of labor and environmental groups, dismissed the Responsible Jewelry Coalition (RJC) as “more shine than substance.” (More Shine Than Substance Report).

The RJC, formed in 2005 by jewelers including Tiffany, Cartier and Rio Tinto, was criticized by the advocacy groups for “poor governance and weak standards,” including a focus on certifying companies holistically, rather than evaluating individual sites and facilities - a labeling practice that pervades the retail sector as a whole. The group’s leadership maintained that it followed standard procedures for verifying sustainability claims.

Still, Kamadoli Costa is optimistic about future opportunities to better leverage input from both competitors and third-party NGOs with direct knowledge of operational pain points.

“The collaborative approach really works,” she said. “It helps move markets.”

The Quest for ‘Sustainable Luxury’

While the jewelry business comes with a very specific set of entrenched challenges related to mining, the industry is also not immune to broader sustainability imperatives such as reducing carbon footprints.

Beyond the new title, Kamadoli Costa has been tasked with further embedding sustainability into the core operations of the New York-based jewelry business, from transitioning to more efficient LED display lighting in the company’s 295 stores to incorporating recycled materials into Tiffany’s famous blue packaging.

The unifying theme, Kamadoli Costa summarized, is “luxury without the environmental cost.”

The decision to buckle down on internal sustainability strategy by promoting Kamadoli Costa to CSO also came directly from the top of the organization; Tiffany’s new CEO, Frédéric Cumenal, created the role. The move underscores the trend toward more explicitly tying environmental and social responsibility to the bottom line, in part to mitigate related risks.

“The Chief Sustainability Officer reports directly to me,” Cumenal wrote in the new sustainability report.

He added that individual department heads at the company with some 12,000 employees also have been tasked with incorporating sustainability priorities into ongoing planning and operations.

“What’s really import from my perspective is what it means internally,” Kamadoli Costa said. “It’s being part of conversations from the beginning.”

Source: GreenBiz