The Supply Chain Link Both Walmart & Amazon Are Missing - The ‘Perfect Order’

“Amazon vs. Walmart” has become shorthand for the competition between online and offline retailers, yet those two channels are likely to become one as brick-and-mortar retailers go online, and e-tailers seek a closer relationship with consumers.

Amazon vs. Walmart

Fortune reported in February that Amazon captured 53 percent of retail e-commerce growth last year to net 43 percent of U.S. online revenue.

That research finding from Slice Intelligence, further revealed a key Amazon advantage: “The average Amazon package was delivered in 3.4 days, compared with 5.6 from everyone else.”

Online competition has led to hundreds of store closures by brick-and-mortar retailers, who continue to retool everything from in-store brand experience to mobile apps and overall e-commerce strategy.

More of their stores offer custom orders, better service to customers who place orders online through their own channels and even orders placed through Amazon.

For its part, Walmart has invested heavily in North American manufacturing, and forged alliances with Facebook, Uber, and Lyft to test and expand options for mobile device-based grocery ordering and delivery.

As early as 2014, MIT Center for Transportation and Logistics’ Dr. Yossi Sheffi predicted that Walmart will win the rapid (same-day) delivery game and beat Amazon. One key reason: the brick-and-mortar giant’s thousands of “small warehouses - they’re called stores.”

Amazon is competing online and off. The company Amazon is operating several brick-and-mortar bookstores with more rollouts planned throughout the year.

Next up: grocery stores that eliminate check-out lines by using sensors to automatically charge shoppers as they pick products and walk out the door. Upstream in the supply chain, investments and/or plans range from warehouse robots to cargo planes and truck trailers to a 2016 patent on blimp-like Airborne Fulfillment Centers to launch drones.

The omnichannel line-blurring between traditional and online retailers will bring new technologies to the fore, but none will address problems both share in common: a lack of data visibility to more efficiently and effectively plan, produce, customize and deliver real products to real people. At present, most supply chains are lacking the critical functionality to do so.

What’s Missing? The ‘Perfect Order’

Upstream of the retailer (or e-tailer) are vast collections of brands, manufacturers, contract manufacturers/packagers, logistics firms and many more suppliers.

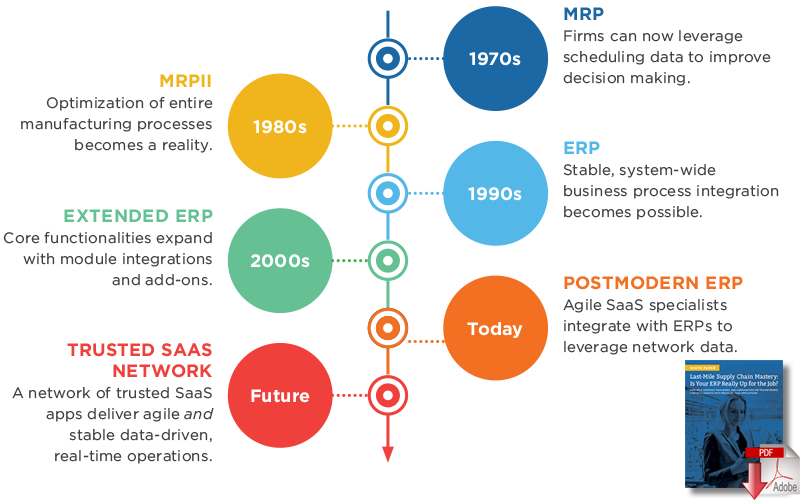

Leading brands long ago adopted enterprise resource planning (ERP) systems, while their suppliers have largely failed to gain usable data in the warehouse management systems (WMS) they use to produce (and customize) products, resorting to oft-cobbled spreadsheet solutions.

Both ERP and WMS systems lack the specificity to properly manage major order execution and fulfillment in the age of mass customization, which increasingly entails manufacturing and packaging outsourcing.

Leading ERP systems are based on the time-honored SCOR Model for characterizing production operations. (APICS pros know the hierarchy well: Plan, Source Make, Deliver, Return; and make-to-stock, make-to-order, etc.) One sub-discipline called “perfect order” has been on the backburner, with proponents waiting for it to become a more practical reality.

One proponent, Dave Blanchard (of IndustryWeek and Material Handling & Logistics), stressed the importance of the perfect order concept as a metric to improve order execution and fulfillment in his book on supply chain best practices. In short, the concept is based on the percentage of error-free steps throughout the life of a purchase order - right product, right condition, delivered on time and damage free, and so on.

The problem is that ERP and WMS systems lack the functional specificity to track operational data at contract packaging and related outsourced locations. Without the right technology to fill the functional gaps, it’s impossible to measure and improve in order to become “more perfect.” SCOR to ongoing work at WERC, the Warehouse Education, and Research Council, we have hope for the further advancement of the perfect order discipline.

As the well-known consultant, Forbes contributor and deep thinker Steve Banker wrote in Logistics Viewpoints, the perfect order metric “is one of the most critical metrics in fulfillment,” and bears close attention.

Brands and their manufacturing and packaging outsourcing partners can use the specific features in solutions such as Nulogy’s PackManager to pursue perfect order-type metrics and key performance indicators.

Rather than target too many variables, experts advise users to start with a few key metrics such as on-time-in-full delivery, correct invoice, and damage-free rates to gain a foothold on optimal execution.

In addition to internal improvements, companies can then target greater integration with partners. When deployed across the operations of multiple supply chain partners, Nulogy says the goal becomes that of achieving a Perfect Order Network™.

The goal is to achieve a unified, collaborative enterprise for last-mile product customization with reductions in waste on a global scale for service to retailers and end-consumers.

The days are long gone when “brand” is synonymous with “manufacturer,” and the technology has advanced to the point where today, it is possible to create a transparent and extended enterprise capable of unifying brands and their last-mile service providers.

Without such integration, the kind of market velocity desired by the Amazons and Walmarts of the world will be hobbled by inefficiency. But when brands and their suppliers share the same data - a single source of the truth - new opportunities emerge.

Of course, new opportunities entail new challenges, including those of giving retailers - online and off - greater data visibility.

“Some large retailers have a far more demanding view of what a perfect order is,” Banker says, adding that “a manufacturer must now collaborate with its retail partners to ensure strong in-stock performance at the retail shelf, which ultimately leads to increased revenues and profits for both parties.”

About the Author

Bob Sperber

Bob joined Nulogy following 30 years of experience as a business, industry and technology media writer and editor. His work with media outlets and marketing clients have imparted in him a solid understanding of the changes, challenges, and opportunities relevant to many sectors of the global economy.

Related Article: The Truth About Growing Your Business in an Age of Personalized Products & Mass Customization

White Paper

Last-Mile Supply Chain Mastery: Is Your ERP Really Up for the Job?

This white paper details how 3pls, contract packagers, and corrugators are transforming last-mile logistics with specialist software-as-a-service applications. Download Now!

Article Topics

Nulogy News & Resources

How to Strengthen Your Position With Consumer Packaged Goods Building Strategic Partnerships Across North America Delivering a Positive Brand Experience Agile Customization Platform Operational Tools Nulogy’s Agile Customization Ecosystem Tools Navigating the Complex Regulatory Environment within Healthcare & Pharma Packaging Customization & Digitalization are Essential for Differentiated CPGs Product Experiences More NulogyLatest in Supply Chain

Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process More Supply Chain