The Benefits of Integrated Lighting & Lenses

Integrated lighting and lens are two of the more recent developments in machine vision technology that deliver even greater convenience and ease-of-use to manufacturers and machine builders.

In this Tech Note, we will identify the benefits of deploying a vision system that features integrated lighting and optics. We specifically highlight the Cognex In-Sight® 7000 vision system that offers these features and detail why this system is the right choice for meeting challenging inspection goals in virtually any production environment.

Benefits of Integrated Lighting

Integrated lighting simplifies the system by eliminating the need to acquire, install and power additional lighting. Having integrated lighting makes the In-Sight 7000 vision system smaller and more compact than others requiring larger external lighting and power, making it easier to install and use in hard-to-reach spaces on the production line. The In-Sight 7000 vision system delivers the added benefit of being able to control the intensity and strobing of integrated and external lights from the system without the need for additional equipment. And since you don’t need to buy additional lighting or power supplies, the In-Sight 7000 is a more cost effective vision system.

Integrated Colored Lighting

Vision system operators use colored lighting to create clearer contrast when inspecting objects. While white lighting is suitable for most vision applications, colored lighting turns an ordinary vision system into a more powerful vision system. The stronger image contrast created by colored lighting delivers more consistent and accurate inspection results. For example, integrated red or green lighting allows users to optimize image contrast and eliminate the influences of factory lighting when used in conjunction with a bandpass filter. As you can see in Figure 1, the red, green and blue colors shown are presented with limited contrast under white light. However, each color is more clearly contrasted when seen with a light of the same color. Under a red light, red appears white. Under a green light, green appears white, and so on. Colored lighting makes it possible for a vision system to inspect a far greater variety of objects and get the repeatable and reliable results you need.

Getting Maximum Benefit

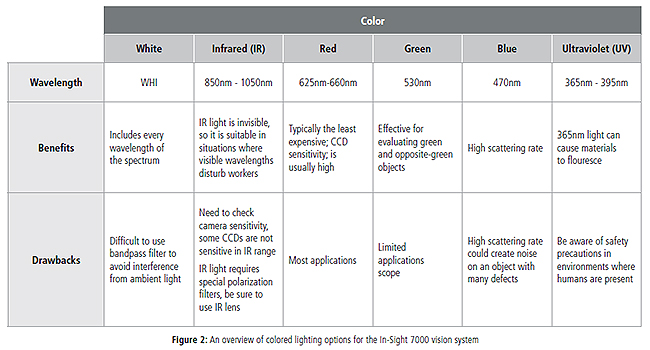

In order to get the maximum benefit from any integrated lighting, you must first identify the type of application you wish to solve—assembly verification, defect inspection, dimensional gauging, Optical Character Recognition (OCR), 1-D or 2-D code-reading, etc. Then you must determine which two (or more) features need to be highlighted or minimized to create the contrast necessary to solve the application. It is also critical to consider ancillary factors such as lighting geometry, pattern, structure and other elements that may influence the effectiveness of white or colored lighting for a specific application. Figure 2 demonstrates more about the benefits and drawbacks of using specific lighting to solve applications with your vision system. A machine vision specialist can help you determine the best integrated lighting choice for your application.

The Benefits of Integrated Optics

In many instances, vision systems featuring integrated optics are not suitable for machine builders and end users because the lenses are not field replaceable. As a result, the system’s flexibility to solve a range of applications is limited.

The integrated optics offered by the In-Sight 7000 are field replaceable and give users total flexibility to support any vision application. Users need only to match the working distance and field of view requirements of each application and select the most appropriate lens for each job. The addition of autofocus functionality complements your lens choice and simplifies the setup of your inspection application.

Autofocus and Integrated Lens

In-Sight 7000 offers the added benefit of autofocus capability for the integrated lenses. Autofocus is a feature that automatically adjusts the vision system’s configuration to focus properly on an object regardless of its distance from the camera. When you save the optimal focus parameters for a specific inspection job in the vision system, you can recall that job at any time from the system. It adjusts automatically for that job to ensure that the area being inspected is in focus. Autofocus affects working distance and field of view requirements and makes it much easier to set up applications and manages lines with multiple part changeovers. To learn more about autofocus technology in vision systems, download the Cognex Tech Note, Benefits of Autofocus Technology in Vision Systems from Cognex.com.

Once a user has determined the appropriate lens for the applications they need to solve, the In-Sight 7000 with autofocus is ready to deploy. Since the lens is integrated, users do not need to be concerned about compatibility issues with the other components of the vision system.

Flexible, easy to use and low cost

A system with integrated lighting and optics solves the most applications at the lowest cost. Since the In-Sight 7000 lighting and optics are field-replaceable, machine builders and end users get maximum flexibility, reduced setup times and save space. Autofocus capability in the In-Sight 7000 vision system makes fine-tuning inspection application and part changeovers even quicker and easier.

Article Topics

Cognex News & Resources

How AI just made label placement better Cognex joins OSARO’s partner program to enhance pick-and-place robotics Transform Your Line Operations Top 20 Automatic Identification and Data Capture Suppliers 2020 Cognex Retail Distribution Logistics Solutions Guide Top 20 Automatic Data Capture Suppliers of 2017 Image-based Scanning for Inbound & Outbound Logistics More CognexLatest in Warehouse|DC

North Carolina Welcomes Amazon’s Newest Mega-Warehouse SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics More Warehouse|DC