Tesla Picks Nevada for $5 Billion ‘Gigafactory’ Plant

The $1.25 billion tax incentive package assembled by Gov. Brian Sandoval to woo Tesla's "Gigafactory" battery plant is unprecedented in size and scope for the state of Nevada and will be one of the largest manufacturing supply chains in the country.

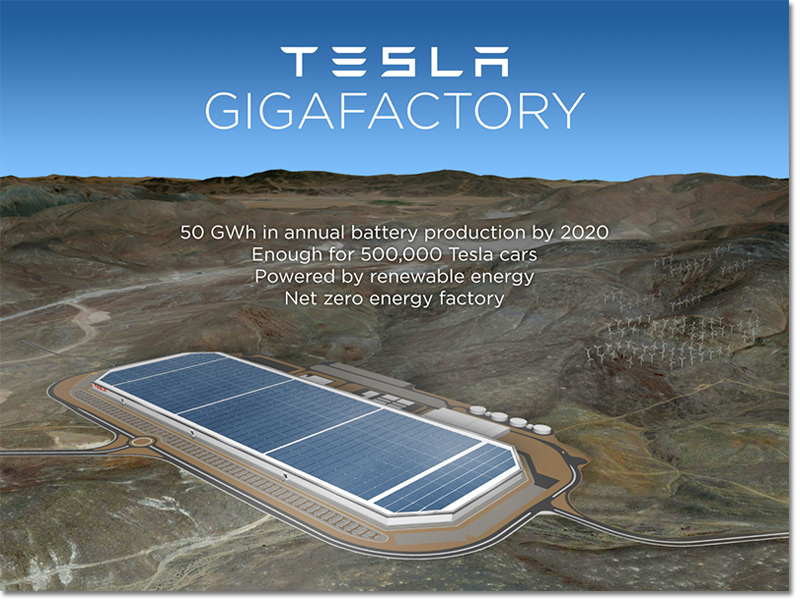

Tesla Motors has selected Nevada as the site for a $5 billion battery factory that will be key to its next generation of electric cars, Nevada Governor Brian Sandoval announced on Thursday.

The California-based electric car maker is still hammering out the final details on the plant that will crank out cheaper and more efficient battery packs for Tesla’s future cars, including the $35,000 Model 3 that is due in 2017.

Japan’s Panasonic Corp will produce lithium ion cells for battery packs and will fund part of the cost of the plant, which is considered an important part of Tesla’s ambitions of taking on major automakers. California, Texas, Arizona and New Mexico were also in competition for the plant.

Nevada Selected As Official Site for Tesla Battery Gigafactory

Thursday, September 4, 2014 Press Release

CARSON CITY, NV – Governor Brian Sandoval and Elon Musk, Chairman and CEO of Tesla Motors, announced today that Nevada has been selected as the official site for the Tesla Gigafactory.

“This is great news for Nevada. Tesla will build the world’s largest and most advanced battery factory in Nevada which means nearly one hundred billion dollars in economic impact to the Silver State over the next twenty years.

I am grateful that Elon Musk and Tesla saw the promise in Nevada. These 21st century pioneers, fueled with innovation and desire, are emboldened by the promise of Nevada to change the world. Nevada is ready to lead,” stated Governor Brian Sandoval.

“I would like to recognize the leadership of Governor Sandoval and the Nevada Legislature for partnering with Tesla to bring the Gigafactory to the state. The Gigafactory is an important step in advancing the cause of sustainable transportation and will enable the mass production of compelling electric vehicles for decades to come. Together with Panasonic and other partners, we look forward to realizing the full potential of this project,” said Elon Musk, Chairman and CEO of Tesla Motors.

“On behalf of the State of Nevada, I would like to acknowledge this monumental day and provide my initial support. This is a significant opportunity to make a major stride to improve our statewide economy. I look forward to receiving the necessary information so the Legislature can meet and take necessary action to support this major industry coming to Nevada,“ stated Speaker Marilyn Kirkpatrick.

The state of Nevada said it will give Tesla more than $1.25 billion in tax breaks and abatements over a 20-year period.

Tesla Chief Executive Officer and co-founder Elon Musk said Nevada’s offer to Tesla “was not the biggest incentive package” but said that the state was picked because it “can do things quickly” and “get things done.”

The Nevada package is subject to approval by the state’s legislature.

The factory’s planned site is in an industrial park in Storey County, about 15 miles east of Reno, Nevada. Only about 4,000 people live in Storey County.

In July, Musk told investors that 40 percent to 50 percent of the cost of a lithium-ion battery plant would be covered by Tesla, with Panasonic funding between 30 percent to 40 percent, and the state where it is located 10 percent.

“Other industrial partners” will provide between 10 percent and 20 percent of the cost of what the company called the “Tesla Gigafactory,” Musk said in July.

The loss-making company expects to build more than 60,000 cars in 2015, after spending heavily this year to update and expand its existing Fremont, California assembly plant.

The automaker has accelerated the expansion of the Fremont plant, which builds the $70,000-plus Model S sedan and will add a companion crossover, the Model X, next spring. Musk said the plant now can build up to 1,000 cars a week, and will double that by the end of next year.

Musk confirmed on Thursday that the company plans to have the mass-market Model 3 ready in three years.

Source: Reuters

Related: Tesla’s Revolutionary Supply Chain

Supply Chain 24/7 coverage on “Tesla Motors”