Supply Chain Risk: 2014 the Hottest Year on Record

Climate change and increasing temperatures now seem inevitable, while there are high levels of uncertainty about the manifestations and magnitude of their impact, what is certain is that climate change will have a multiplier effect on supply chain risk.

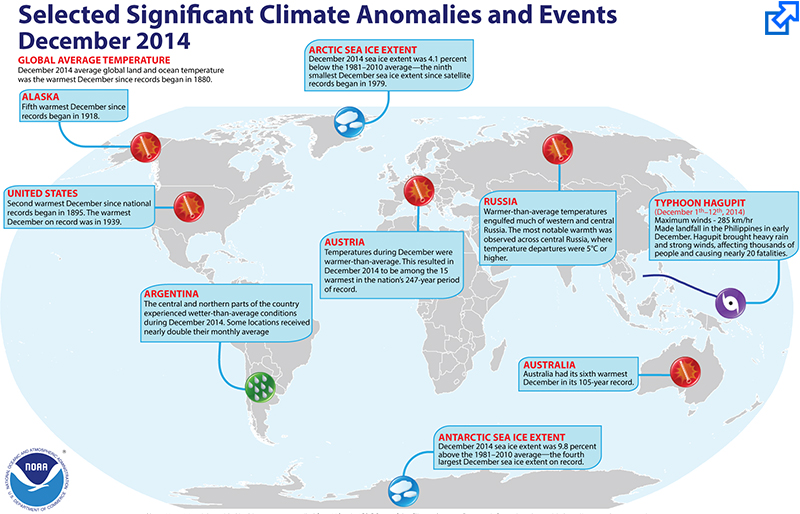

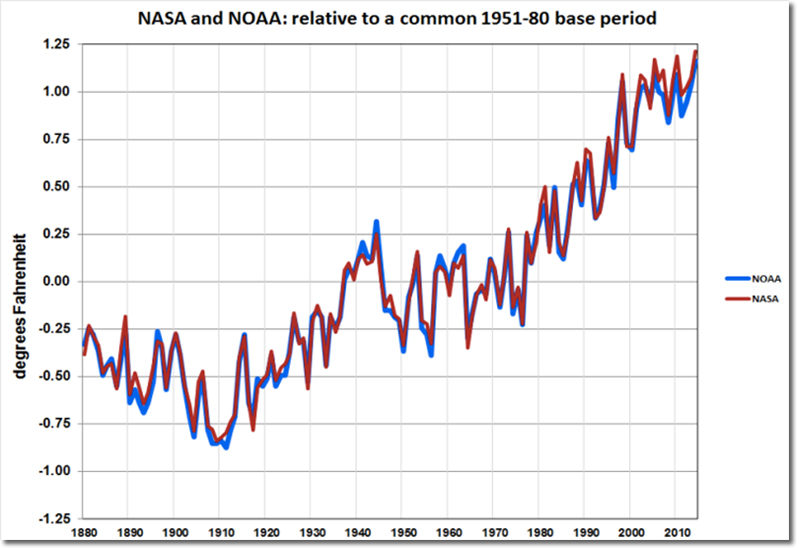

Global warming is still with us. 2014 was Earth’s hottest year since records began in 1880, according to new analyses from both NASA and the National Oceanic and Atmospheric Administration.

The global average temperature for 2014 was 1.24°F (or 0.69°C) warmer than the average during the twentieth century, NOAA said.

The year featured record heat in the western United States, Europe, Australia, and much of the Pacific Ocean.

The previous hottest year on record had been 2010, followed by 2005 and 1998. NASA and NOAA both said the 10 hottest years have all come since 1998, a sign that the Earth is steadily getting warmer. (Both agencies use a network of satellites, thermometers, buoys, radar, and other tools to track trends.)

“If you are younger than 29 years old, you haven’t lived in a month that was cooler than the 20th-century average,” said Marshall Shepherd, a meteorologist at the University of Georgia.

More broadly, average temperatures have now risen 1.4°F (0.8°C) since the 19th century. Climate scientists expect the Earth to keep getting hotter over time so long as humans keep adding greenhouse gases to the atmosphere. There are short-term variations from year to year - for instance, El Niño years like 1998 tend to be a bit hotter, while La Niña years are a bit cooler - so not every year will necessarily set heat records, but the overall trend is up.

It’s also worth clarifying that 2014 wasn’t the hottest year in the planet’s entire history. The Earth has been even hotter in the distant past, before human civilization arose - a result of natural processes and orbital shifts. But the Earth’s climate had roughly stabilized over the last 10,000 years until humans began clearing forests, burning fossil fuels, and emitting greenhouse gases. Scientists say the sharp rise in temperatures in the 20th century is a sign of man-made warming.

Source: Vox

Related: New ND-GAIN Partnership Addresses Climate Risk in Supply Chains

Business-Not-As-Usual: The Impact of Climate Change on Supply Chain Risk

While climate change and increasing temperatures now seem inevitable, there are high levels of uncertainty about the manifestations and magnitude of their impact. What is certain, though, is that climate change will have a multiplier effect on supply chain risk.

In 2010, Russia suffered a severe heat wave. The resulting economic losses were estimated to be US$15bn as drought and wildfires destroyed crops, particularly wheat. The knock-on effect was export restrictions on wheat in Russia, which contributed to global price increases.

Anticipating and responding to risks is business-as-usual for all sectors. This example is from the agricultural sector. It is one of many one could choose from sectors that are dependent on physical produce, such as agricultural, fuel or mining and metals commodities. These industries are no strangers to dealing with the risks of supply-chain disruption (e.g. wheat shortages), both man-made (export restrictions) and natural (weather, drought, etc.). What is changing is the complexity of the risks, their interdependence with other risks and the wide-reaching, contagious impact they have (e.g. global price rises).

But the other major factor set to exacerbate supply-chain risk is climate change. Often overlooked, climate change adds to complexity. It amplifies or alters existing risks, for example raw material availability (e.g. water, energy) or transport disruption due to extreme weather events. The resulting shocks on the global supply chain can be severe and persistent.

So climate change is a ‘risk multiplier’. But businesses have yet to gain the full measure of its effect on their supply chains. How serious? How soon? How likely? How wide? How to mitigate?

Which supply chains need to strengthen their links?

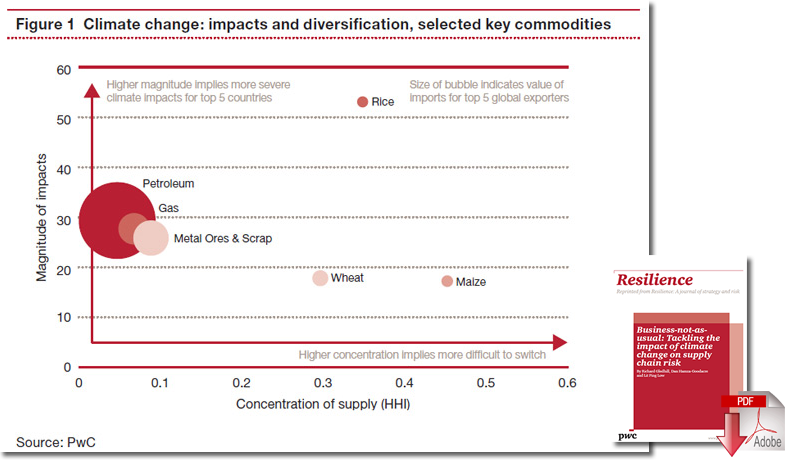

What is the likelihood that climate change risk could disrupt certain supply chains? To answer this question, we have analysed the threats posed by climate change to a selection of commodities:

- Agricultural (wheat, maize and rice)

- Energy (petroleum and gas)

- Mining (metal ores)

We have looked at the two major factors that have the greatest influence on risk exposure:

1. The magnitude of impact of climate change on the commodity:

This depends on: i) how susceptible a commodity is to the effects of changes in temperature and precipitation, rise in sea levels and occurrence of storms and flooding; and, ii) how able the supplying country is to cope with the potential effects of climate change. This is based on factors such as political stability, governance, macro- and socioeconomic development of a country.

2. The concentration of suppliers:

In general, where a commodity can be sourced from a diverse range of suppliers, supply disruption can be lessened as buyers turn to alternative suppliers. Conversely, where a commodity is concentrated in a small number of suppliers, disruption for any one major supplier can have global implications.

We have mapped these factors in Figure 1. It shows the extent to which the top five country exporters of these commodities are exposed to climate change impacts (vertical axis), and the degree of global supply concentration of these commodities (horizontal axis).

Multiplier effect needs multilateral efforts

How can organisations start to mitigate the potential disruption on supply chains due to climate change risk? The UN negotiations in Doha concluded with limited progress, with current pledges still falling short of what is needed. Businesses and governments can improve readiness by adopting these three principles:

1. Don’t view risks in isolation.

Businesses need to identify not just the risks emerging from the impacts of climate change, but how the resulting impacts interact with existing risks.

2. Start scenario planning and put risk management procedures in place.

Governments and the business community need to start considering risk management plans in a world with a climate change of not just 2oC, but also 4oC or even 6oC. Effects are already being felt in some regions and they are projected to worsen globally.

3. Collaborate and give greater attention to international resource security.

Competition for scarce resources may intensify, and can be compounded by political and economic developments. Developing a collaborative and sustainable resource management strategy at a global level can help avoid the risks of ‘resource grab’ and conflicts.

Photo Source: Knowledge Overflow

Related: Supply Chain Managers: What You Need to Know About Climate Change

Article Topics

eShipGlobal News & Resources

Supply Chain Risk: 2014 the Hottest Year on Record Supply Chain Managers: What You Need to Know About Climate Change Climate Change Risks and Supply Chain ResponsibilityLatest in Supply Chain

U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam More Supply Chain