Supply Chain Planning & Execution – Merge Ahead

In the last two decades there have been many innovations in advanced planning systems such as new forecasting algorithms, multi-echelon inventory optimization and transportation planning just to name a few.

In today’s digitized and connected world, we have become ever more demanding and fickle consumers.

If we don’t get what we want, when we want it, where we want it, our way, we dump a brand in a click!

Consumer behavior and expectations have crossed critical inflection points. Omni-channel commerce necessitates highly adaptive and nimble supply chains.

Ready or not, real time is becoming the basic expectation and supply chain latency will no longer be tolerated. The traditional approach of planning and execution in sequential waterfall processes has too many divisions, too much iteration, too much complexity and far too much latency to be able to cope with this dynamic environment.

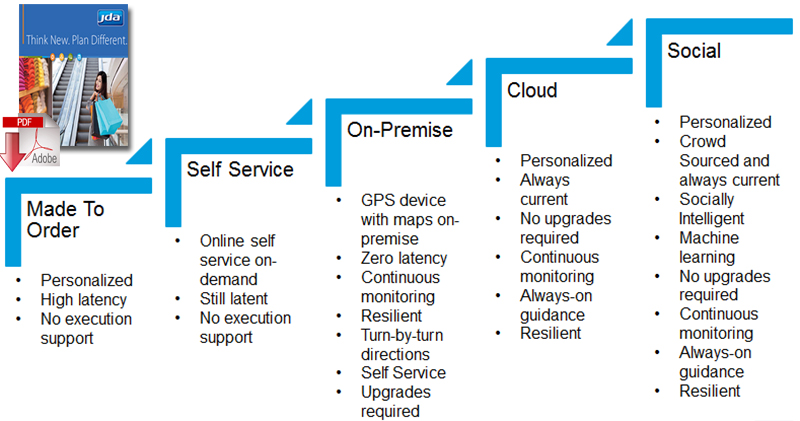

In order to better understand the opportunities before us for the future of planning and execution, I believe we can look at how road navigation has evolved over the years.

Getting There – Then and Now

Not too many years ago planning a road trip involved getting a “Trip-Tik” made from the Automobile Association. We discussed our travel requirements with a travel agent and then a few days later picked up a detailed trip route that was prepared just for us.

The agent would have used a highlighter to mark our entire route on handy flip-page maps that we could refer to while driving. We were also given helpful tour books that listed hotels, restaurants and sites along the way.

This worked well as long as we could wait to get the maps prepared. Also, we had to figure out detours ourselves if there was new construction or other obstacles on the roads.

Later, online mapping applications such as MapQuest offered a no-waiting self-service solution where we could generate a trip route online and print the maps ourselves.

However, we were still on our own once we were on the road.

Related: Mapping Supply Chains in the Global Economy

The advent of GPS devices yet a few years later was a big leap forward. These devices not only let us plan our routes and take the maps along for the ride but they also tracked our position and immediately offered an updated plan if we went off-course. However, since they were stored on-premise on the individual devices themselves, the maps had a tendency to go stale and we needed to buy and install upgrades regularly.

Today’s smartphone apps regularly update maps and automatically make them available to every user via the Cloud. The cloud-based deployment model has eliminated the need for upgrading maps on your device.

The most recent advancement in road navigation is coming from the use of crowd-sourcing and machine learning. Google crowd-sources traffic congestion data by monitoring speed of thousands of individual smartphones using Google Maps on the roads. Crowd-sourcing also helps keep maps up-to-date. The more people use an app, the more accurate and useful its information gets. Waze, another navigation application, delivers a socially intelligent solution where you can track the whereabouts of your friends, share routes and coordinate pickups. Waze dynamically tracks and “learns” the traffic patterns for individuals and communities.

We have certainly come a long way from the Trip-Tik days!

Now, let us compare this journey to where we are with planning and execution practices:

Orchestrating the Supply Chain – Now and in the Future

In the last two decades there have been many innovations in advanced planning systems such as new forecasting algorithms, multi-echelon inventory optimization and transportation planning just to name a few.

However we are still living in the paradigm where plans are developed periodically and then thrown over the wall to execution. Planning is quite isolated from execution. The updated snapshot of planning input data is perhaps the only indirect connection to execution. There is little or no monitoring of execution against plan during execution. Measurements of performance against plan are typically done only as periodic post-mortems.

Clearly there are several flaws such as lack of visibility and latency with the current approach. To eliminate these, I believe there will be major changes in the way we will orchestrate supply chains going forward.

Real Time Visibility

For decades, transaction systems such as order entry, transportation execution and warehouse execution have evolved in silos too far removed from supply chain and replenishment planning. Real time status is only known to execution systems and snapshots are passed periodically in batch data transfers to planning systems. In road navigation, it was GPS technology that enabled us for the first time to know where we are while driving and if we are tracking to the planned route.

The same juxtaposition of plan and real time state visibility is now taking shape in supply chain execution. Gradually, everything and everyone in the commerce network will be connected via the Cloud. Eventually, orders from any channel will propagate across the value chain instantly and without touch. Shipments will identify themselves and tell you where they are at all times. One will be able to tell where an order is, what orders are in a load, what loads are on which truck, when certain orders will be unloaded or loaded in a warehouse … and so on.

Continuous Planning

Many tackle plan latency with frequent re-planning or collaborative resolution of disruptions but these high-touch approaches need significant manual intervention. This is akin to stopping more frequently to ask where you are and getting fresh directions. Faster waterfalls between planning and execution will not be enough. In the future, there will be a new paradigm for continuous execution guided by continuous visibility and continuous planning. We will always be executing, always be monitoring and always be planning in real time –simultaneously.

Smart Decision Support

Some argue that with so much uncertainty there is no point in planning. I disagree. When a navigation app shows you alternate routes for a given destination, you have visibility to tradeoffs such as choosing between shortest and fastest routes or choosing to avoid toll roads, and so on. The mere act of planning provides a structured framework to articulate the objectives, evaluate the trade-offs, anticipate risks, plan contingencies and agree on a course of action.

I have written about the value of proactive risk-aware planning and process playbooks in an earlier Supply Chain Nation post. Planning is essential to superior performance. No matter how fast, reactive decision making with “guess and check” simulations alone will not be enough. Optimized planning will remain essential to superior and profitable execution. In the future, intelligent decision support will simply become part of execution itself. Plans will evolve as uncertainties unfold. Execution decisions and response to unplanned events will be guided by optimized incremental planning.

Intuitive and low-touch experience

Just as road navigation apps have evolved to become very personalized, adaptive and context aware, planning and execution solutions will be tailored to individuals, their role and their commerce communities. Solutions of the future will offer role and task specific personalized views and a frictionless user experience.

Are We There Yet?

Continuous planning and execution is not an elusive vision. The good news is that the industry is already making good progress along this path. There have been breakthrough advances in networked communities, cloud computing, machine learning, and in-memory technologies that open up possibilities that were perhaps unimaginable just 5 to 10 years ago.

Related: 7 Reasons For Supply Chain Planning Software

Article Topics

Blue Yonder News & Resources

Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Frictionless Podcast: Understanding Your Supply Chain Goals with Ann Marie Jonkman Blue Yonder announces acquisition of flexis AG Supply Chain Management (SCM) applications keep the supply chain humming How Collaborative Efforts Can Enhance Reverse Logistics Netlogistik partners with SVT Robotics to resell SOFTBOT platform More Blue YonderLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain