Supply Chain Planning & Inventory Optimization

Supplying holiday fireworks is challenging, supply chain professionals from thousands of different companies supplying consumable and non-consumable products have to consider past demand trends and predict their products’ demand especially for the US 4th of July holiday.

Holidays are complex.

Take for example the upcoming Fourth of July holiday in the USA.

As a child, this holiday always represented the best of the summer break and often included fun activities like camping, fishing, spending time in a park, parades, and wonderful firework displays.

Of course there was always the abundance of kid friendly foods like hot dogs, hamburgers, bratwurst, watermelon (and the ensuing watermelon seed spitting distance contest), chips of all kinds, and lots of sugary drinks.

As an adult, watching your child experience the 4th just makes the holiday even more enjoyable.

Most people don’t think about all the planning that needs to take place in the months leading up to the 4th to make sure everything is available to make this US holiday a success.

However, supply chain professionals from thousands of different companies supplying consumable and non-consumable products have to consider past demand trends and predict their products’ demand for the upcoming holiday.

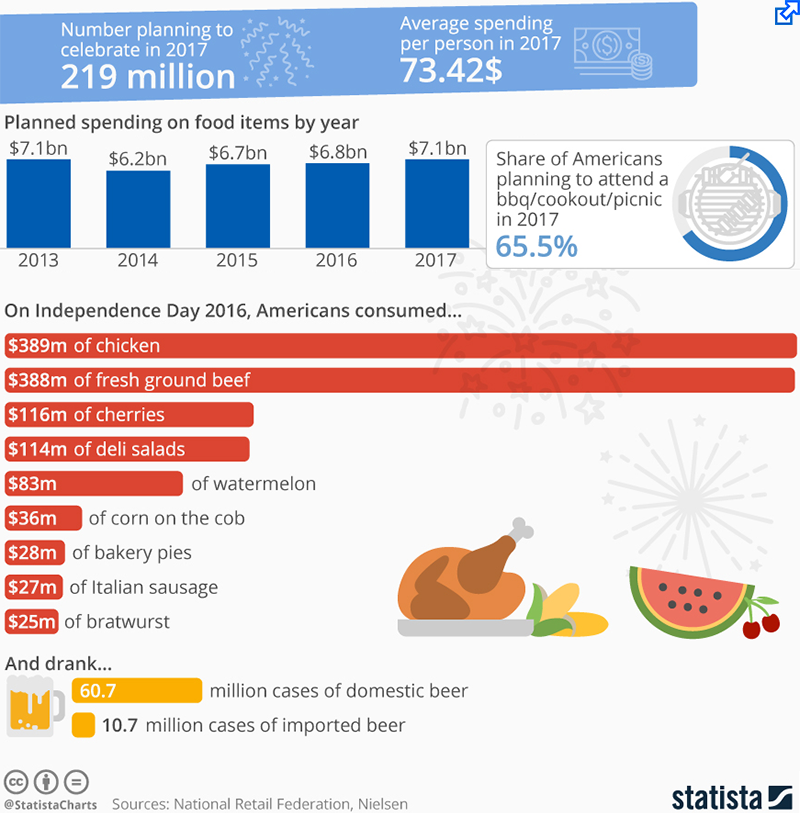

Independence Day by the Numbers

Forecasts for everything from paper plates and plastic utensils, to charcoal and lighter fluid, to suntan lotion, to food and drink of all kinds and even the amount of gasoline available for summer trips have to be created.

Procurement and manufacturing plans need to be created and executed based on forecasts. The positioning of products in the supply chain needs to be carefully planned to meet projected needs in each market and to be able to quickly respond to shortages as they occur.

No small effort to ensure millions of people in the US have a memorable 4th of July.

Planning for Holidays is a Complex Process

Creating accurate forecasts for holiday demand using a spreadsheet or basic forecasting capabilities available in ERP packages is almost impossible and will surely dampen everyone’s holiday spirits.

For the average person this is just a normal holiday but for supply chain professionals this single day encompasses a lot of variables that contribute to a complex operation.

Factors including the day of the week the holiday falls on, regional item preferences and variations in weather, just to name a few, must be considered. These are near impossible to model accurately with basic tools.

Accurate forecasts for new products introduced since the last holiday are critical. These are often the products with the highest margins while also the hardest to forecast.

Planners must account for timing variations while building accurate projections at multiple levels of aggregation to account for local trends. Product lifecycle planning capabilities including family launch curves built through product attribute segmentation and special new product forecasting algorithms ensures a steady supply of the newest products.

For many products, demand generated from holidays like the Fourth of July represents a significant portion of total yearly sales. Short-term demand often outstrips short-term production capabilities requiring pre-building based on an extended forecast.

Long-term forecast accuracy is vital for determining pre-build / pre-purchase inventory plans. Supply chain planning and optimization helps determine when and from whom to purchase materials and when and where to manufacture products to maximize customer service while minimizing total supply chain costs.

Weather patterns can drastically influence the demand for holiday products. It is essential to have a well-developed inventory deployment plan to ensure local demands can be met. In many cases if your products are not available, the consumer will purchase competing products to meet their holiday needs.

Multi-echelon inventory optimization (MEIO) is another capability that can deliver significant results for today’s complex supply chain.

MEIO (read more: The Two Levers of Inventory Optimization) can be used to determine optimal inventory buffer locations and the quantities of each item to deploy at each location.

The use of MEIO to plan for holidays can increase accuracy of the initial market and store allocation and improve the supply chains ability to respond to unexpected demand variations leading up to and during the holiday.

Next time you shop for all your holiday necessities stop and think about all the efforts by supply chain planning professionals to ensure you have everything you need to make your event memorable.

Article Topics

Logility News & Resources

Logility makes entrance into supply chain-focused AI, with acquisition of Garvis Logility Acquires Generative AI Supply Chain Planning Firm Garvis Supply chain software platforms help to level the playing field Logility to acquire supply chain network optimization vendor Starboard Solutions Logility partners with Körber to expand capabilities How Does IKEA’s Inventory Management Supply Chain Strategy Really Work? This is Not Your Father’s Inventory Optimization More LogilityLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain