Supply Chain Managers: What You Need to Know About Climate Change

Based on the astute observations in the OXFAM study, it seems we have a lot of room to grow when it comes to how companies invest in building sustainable supply chains, specifically those affecting small-scale producers.

By nature a chain is comprised of a series of links, each interdependent on the next.

The supply chain is no different. Though the links may be intangibles like materials, distributors, retailers and customers, each piece serves as an important function without which business grinds to an unprofitable halt.

Staying ahead of potential risks before they become real threats is merely part of the deal when you run a business, but what about those factors that you can’t anticipate - much less control?

For example, how does a successful business prepare for or even begin to respond to factors that can disrupt the production of essential raw materials such as agriculture, fuel or mining and metals commodities? By knocking out this first essential step, the entire supply chain collapses before it’s even fully formed.

At this point, any good supply chain manager might be thinking to themselves, “Sure, but we have contingency plans in place to address natural disasters or man-made supply-chain disruptions such as export restrictions.”

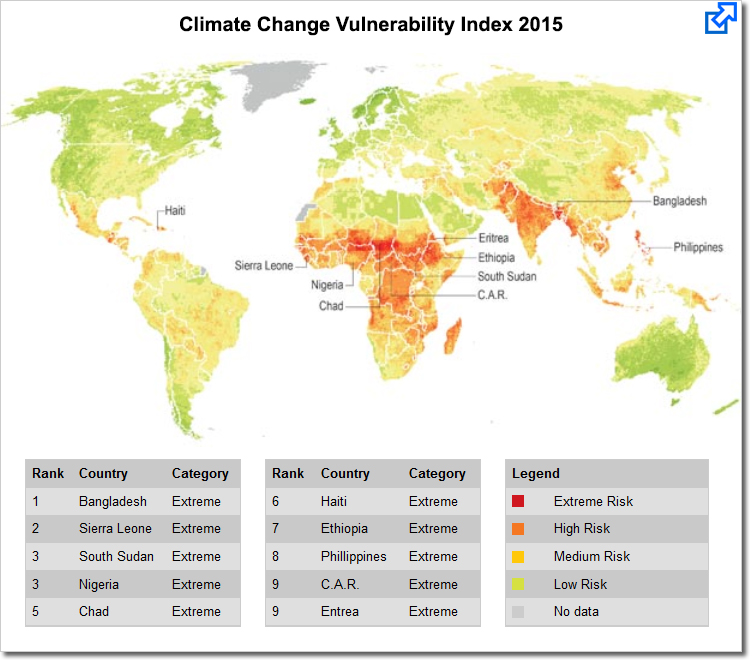

That may be true. However, this doesn’t take into account the long-term fallout of the Big C - climate change. Businesses often overlook this critical piece, adopting a “if it ain’t broke, don’t fix it” mentality. Sooner or later, chances are these marked changes in our atmosphere will amplify, alter or exacerbate issues in raw material availability or their transportation thereof.

As a company whose sole business is to ensure that the distribution portion of your business model is solid, our ears perk up when we hear about potential catastrophic disruptions which could ultimately result in a global supply chain shockwave. Perhaps that sounds a bit drastic, but working to mitigate these risks in the daunting face of climate change is something all businesses would do well to keep on their radar.

Thanks to a recent study compiled in an OXFAM discussion paper, policy advisors and consultants laid a comprehensive foundation for how we can build sustainable supply chains that potentially have the power to affectively deal with, and possibly avoid, the risks of severe climate change.

Through their three case studies, they effectively illustrate, “how weather events are affecting producers: increasing their costs; threatening the quantity and quality of production; and making decisions about planting and harvesting increasingly difficult.”

Still asking, “But why should I care?” Are you one of the overwhelming majority of companies the Organization for Economic Co-operation and Development (OECD) pegged as being “generally aware of the physical impacts of climate change,” yet who fail to, “undertake formal assessments of the specific risks they face and follow up with action on adaptation to reduce those risks?”

If so, you may find these five OXFAM recommendations of interest.

- Adopt a culture of awareness and full understanding that adaptation is essential for successful supply chain security. After all, being proactive trumps being reactive every time.

- Assess your risks. Speak directly with the producers of your raw materials, learn their pain points, learn their day to day struggles, and act accordingly.

- It’s all about stable relationships, especially those with your suppliers. You need them and they need you. By forging longer-term bonds you foster a trust which ultimately enables those producers to sign on as suppliers over the long run. It’s the ‘happy wife, happy life’ of supply chain security.

- This next one is a big one, so listen up. “Support community development and environmental sustainability.” We need both to live out long, happy, uninterrupted lives if we are to protect from environmental degradation which could erode our global ability to produce. In doing so they suggest simple measures such as supporting things like climate-resilient agricultural practices as well as cooperatives and other producer organizations, promoting avenues for income diversification and food security within the household, and providing additional markets for new crops.

- Collaborate as an international community to spread the word about resource security. As the inevitable slew of political and economic developments continue, it’s possible, perhaps probable, that the scarcity of certain resources will spur competition. As such, companies are encouraged to develop collaborative, sustainable global resource management strategies.

Based on the astute observations in the OXFAM study, it seems we have a lot of room to grow when it comes to how companies invest in building sustainable supply chains, specifically those affecting small-scale producers.

While it’s true that scientific uncertainties surrounding when, where, and how drastic climate impacts may make it impossible to fully plan for these physical risks, it’s important that even those who are one step removed from the production process, be aware of potentially limiting, and severely damaging practices which affect the global supply chain and all of our bottom lines.

About the Author

Srini Vasan is the CEO of eShipGlobal, an on demand transportation management solution provider, which prides itself on bringing business applications to the market quickly and helping customers manage their transportation effectively. Vasan is currently involved in business development and oversees technology infrastructure and software development.

Source: TriplePundit

Image: Saint Petersblog

Article Topics

eShipGlobal News & Resources

Supply Chain Risk: 2014 the Hottest Year on Record Supply Chain Managers: What You Need to Know About Climate Change Climate Change Risks and Supply Chain ResponsibilityLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain