Supply Chain Collaboration Shouldn’t Be Complicated

Your executives need data to make the right decisions, your workers need data to take the right actions, your trading partners need data to deliver the right inventory to the right place at the right time, and you can’t afford a single communications delay or disconnected data transmission.

Why You Need a True Supply Chain Orchestration Engine Powering Your ERP

Every supply chain can benefit from an orchestration platform that provides the following capabilities:

- Multiple integration options to directly connect your business systems with your external suppliers;

- A workflow and messaging engine that can map to your existing business processes; and

- An end-to-end visibility and collaboration portal that enables all internal and external stakeholders to stay in step with your business in real time, in one place.

However, the reality is that most software claiming to be a supply chain “solution” lacks the ability to address more than one or two of these capabilities at a time.

That is why most software solutions fail to fully solve all of your problems.

It is also the reason why many organizations are still burdened by numerous, often disconnected, data systems.

More systems do not automatically equate to more collaborative supplier interactions and well-orchestrated supply chains.

In fact, executives made it clear in a recent Supply Chain Digest study that the following items remain the top three barriers to improved supply chain performance:

- Lack of ability to design/execute “end to end” processes

- Level of supply chain technology support

- Lack of internal collaboration across functions

Executives are also struggling with the “lack of external collaboration with trading partners”.

Fortunately, there are supply chain management (SCM) platforms that are capable of resolving each of these barriers. They do so by serving as true supply chain orchestration platforms.

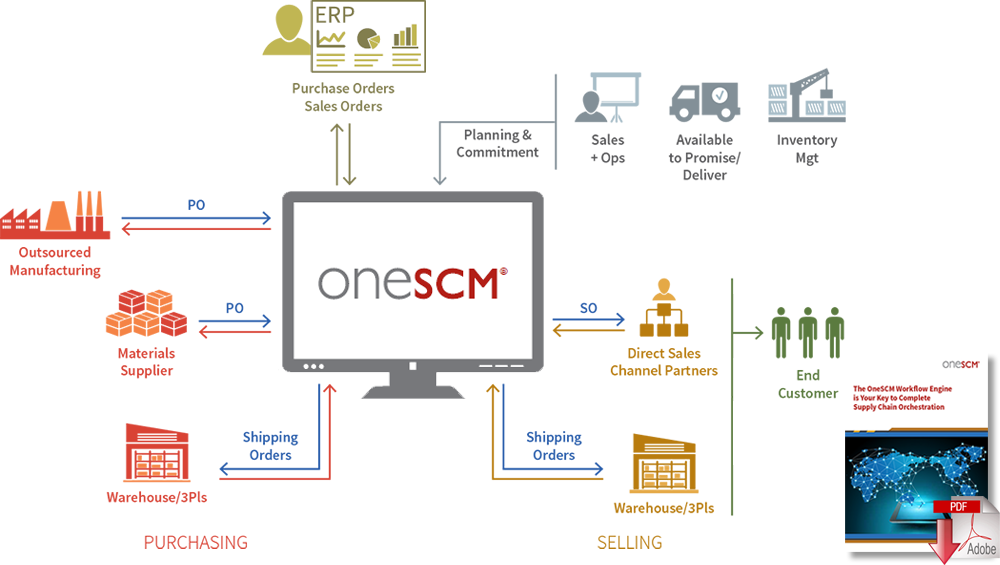

The key is to look for a SCM platform that sits right in the middle of your organization and becomes the central “command and control tower” for all data, interactions, and systems. The platform you choose should be able to directly connect every one of your business systems with every one of your internal stakeholders and suppliers. It should also provide a single, web-based portal that’s accessible from practically any device, anywhere.

You know you’ve found a winning Supply Chain Orchestration solution when you can finally:

- Design/execute those “end to end” processes. The ideal SCM platform will be built upon a workflow and messaging engine that can quickly and easily design an “end to end” business process. It should enable you to automate workflows, and data flow, from purchasing to payment to achieve a more efficient manage-by-exception environment. And, you should not have to re-engineer business systems or processes.

- Recover valuable time and IT resources that are currently being wasted by managing individual B2B connections and system profile mappings. Again, ask if your SCM solution provider supports the multiple integration options that are currently in use in your supply chain environment, regardless of the system to which you are connecting. If the answer is no, then you will not have proper technology support for your demanding supply chain operations.

- Increase collaboration with suppliers of varying volume, technology, and integration levels. This will provide better access to critical decision-making data. In turn, you’ll benefit from more coordinated supply chain planning and execution strategy. Just be sure the supply-chain wide “management” portal enables, and encourages, all stakeholders to document their actions and communicate with one another in real time, in one place, online. This end-to-end visibility and cross-function collaboration will instill confidence in your stakeholders.

If you prioritize your investment in this type of SCM solution, then you will quickly see more frequent and quality interactions between suppliers, finance, procurement, logistics, production, and accounts payable.

With access to every communication, transaction and supplier record consolidated in one place, you will also have a way to confidently deal with urgent issues in real time. And, you will have the tools to more effectively measure and improve the performance of your entire supply chain.

Bottom line

Your executives need data to make the right decisions. Your workers need data to take the right actions. Your trading partners need data to deliver the right inventory to the right place at the right time. You can’t afford a single communications delay or disconnected data transmission.

That is why you should not ask either internal stakeholders or external suppliers to collaborate via email, the ERP or any “communication” method other than a Supply Chain Orchestration and Workflow Engine such as OneSCM.

OneSCM Orchestration Environment

Learn about all of the advantages of choosing a supply chain management platform that's powered by a workflow engine and accessed via a single portal. (Complete stakeholder collaboration and supply chain orchestration are just the beginning.)

Download: The OneSCM Workflow Engine is Your Key to Complete Supply Chain Orchestration

Article Topics

TAKE Supply Chain News & Resources

5 Ways Businesses Benefit from the Right Supply Chain Orchestration Platform Break Down Costly Supply Chain Data Silos Once and For All Workflow Engine is Your Key to Complete Supply Chain Orchestration How Supply Chain Orchestration Boosts Agility, Simplicity and Business Performance Game Over as Bankrupt Toys ‘R’ Us Files for Liquidation and Begins US & UK Store Closures What Is Supply Chain Orchestration (Really) – And Is It Even Possible? Supply Chain Collaboration Shouldn’t Be Complicated More TAKE Supply ChainLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain