Study Assesses Five Technologies to Impact the Supply Chain in the Next 5 Years

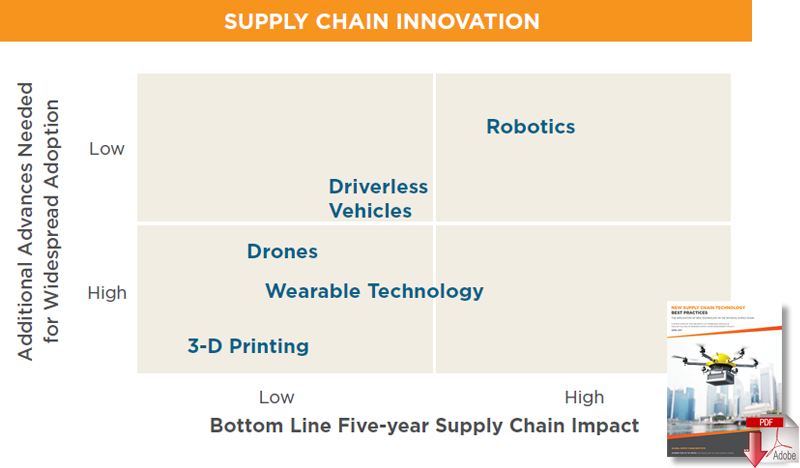

Robotics tops the list of most likely disruptors in next five years, 3D printing considered least viable in the short term.

A new study from the University of Tennessee, Knoxville’s Global Supply Chain Institute identifies five technologies that companies should examine to ensure their long-term survival as a flood of new technologies in the past decade foretells a supply chain revolution.

The white paper looks at drones, driverless vehicles, 3-D printing, wearable technology and robotics.

It assesses the current and potential use of these technologies as well as the benefits and barriers to using them.

Of these technologies, the experts consider robotics to be the greatest potential disruptor over the next five years.

“Robotics have been around for more than 50 years, but they have become dramatically more dynamic in the last five,” said Paul Dittmann, executive director of the Global Supply Chain Institute and author of the paper.

“They are no longer stationary, blind, expensive and unintelligent but can work alongside people and learn as jobs change.”

Drones might not be ready for their anticipated role in last-mile delivery of consumer goods but are close to helping with less technically challenging tasks such as tracking warehouse inventories or managing trailer yard security.

Wearable technologies like smart glasses will likewise find application in the warehouse, helping workers sort, pack and inventory items as well as identifying safety hazards or the shortest path to their next pick.

Driverless vehicles have already been tested and approved in seven states and will substantially affect transportation costs once they can be caravanned or reach a port-to-port automation point.

Considered the least viable in the short term, 3-D printing is identified as having the potential to eliminate the supply chain completely if costs can be reduced and usable materials expanded.

The report notes that these physical technologies are inextricably linked to digital innovations like big data and the Internet of Things.

Real breakthroughs will require a seamless link among the physical devices and their digital and software interfaces.

“We are at a turning point in the industry where disruptive innovation is required to meet the exponentially growing customer expectations,” said Danny Halim, vice president of distribution and 3PL strategies at JDA Software.

Dittmann tapped a wide range of expert sources, including multiple large and well-known companies, service providers and technology start-ups, to author the white paper, “New Supply Chain Technology Best Practices.” It is the first in UT’s Technology in the Supply Chain series.

Kenco Logistics and JDA Software sponsored the paper.

Article Topics

Blue Yonder News & Resources

Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Frictionless Podcast: Understanding Your Supply Chain Goals with Ann Marie Jonkman Blue Yonder announces acquisition of flexis AG Supply Chain Management (SCM) applications keep the supply chain humming How Collaborative Efforts Can Enhance Reverse Logistics Netlogistik partners with SVT Robotics to resell SOFTBOT platform More Blue YonderLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain