Students Claim They Have Designed the Perfect Packing Container

The Rapid Packing Container, a new design for the cardboard box invented by two current students at the Albert Nerken School of Engineering.

Two Cooper Union engineering students, Henry Wang and Chris Curro, claim the new box design will “revolutionize the cardboard packing industry” as it is more environmentally-friendly, quicker to pack, and easier to open, store and recycle.

While the Rapid Packing Container certainly has some exciting features (and it is clear that Henry and Chris have bright futures ahead of them), this packaging engineer is not sold.

Here’s a few of my thoughts on the new design, and why it may fall short of revolutionary:

- Traditional corrugated boxes are extremely efficient. The student engineers claim that traditional “cardboard” boxes are wasteful, hard to open, and difficult to pack. (Read why the term “cardboard” makes me cringe here.) While the last two statements in their claim are fairly subjective and, if true, indicative a much bigger process problem, I disagree with the first assertion.

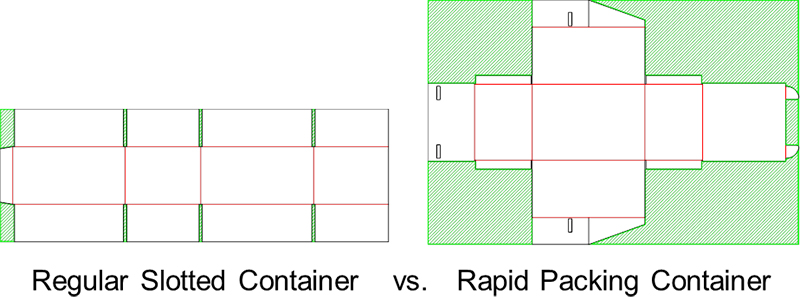

From a material usage standpoint, there is hardly any waste in a Regular Slotted Container (RSC). To manufacture a RSC that is 12 inches by 8 inches by 6 inches, it requires 600 square inches of corrugated material. The final product contains 577 square inches of material, which means only 3.7% of the material is unused or wasted. In contrast, a Rapid Packing Container of the same size requires 1,133 square inches of corrugated material, and creates 47.9% waste.

Two-dimensional views of each layout make it easy to see how much waste is produced.

- Scalability is a must for real world applications. The jig is a nice feature to speed up the set-up process. But, can you imagine how this would work in a facility that ships hundreds of SKUs in all different shapes and sizes? Each packing station or line would need at least a dozen jigs to accommodate every possible box size. This diminishes the practicality of the Rapid Packing Container for large operations.

- Distribution trumps design. The tapeless, easy-open features of the Rapid Packing Container are appealing, but if the box really is that easy to open, it may introduce a number of distribution challenges. How will the box perform when it travels through multiple conveyor systems or when it is manually handled, tossed, dropped, and stacked? It reminds me that ASTM D-1974 (Standard Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes) exists for a reason. It is imperative that shipping cases remain closed during distribution and transport.

That being said, the Rapid Packing Container may be a good fit for a small or niche business, such as a bakery or boutique. And, I am impressed by the efforts of Henry and Chris, and look forward to seeing more from the next generation of engineers.

Source: Packing Matters

Packaging Matters blog is a compilation of articles, excerpts, and opinion pieces on general packaging topics brought to you by a group of Certified Packaging Professionals (CPP). Powered by Chainalytics

Article Topics

Chainalytics News & Resources

Modern Shipper-3PL Relationships Prioritize Collaborative Growth and Improvement Supply Chain Leaders Learn From Today’s Ecommerce Challenges to Provide Future Innovation and Growth 60 Seconds with Kyle Ous, Senior Manager of Packaging at Chainalytics 60 Seconds with… Kyle Ous, Chainalytics Chainalytics and Drewry team up to create ocean buying group NextGen Supply Chain: We gonna rock down to Electric Avenue? NextGen Supply Chain: We gonna rock down to Electric Avenue? More ChainalyticsLatest in Warehouse|DC

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring More Warehouse|DC