Rock the Docks-What ePOD Brings to Cross-Docking

Effective cross-docking requires real-time visibility of goods as they are received, staged, loaded and distributed to their final destination.

Cross-docking is not a new idea – in fact, the practice first started in the 1930s when supply chain moguls were looking for ways to cut costs and improve the speed with which goods made it to consumers.

Well, fast forward 80 years and the industry is still looking for ways to improve the speed and efficiency of delivering goods to customers at the lowest possible cost.

They say that history repeats itself and that smart ways of doing business never go out of style, so it’s no surprise that cross-docking has come back into vogue in recent years.

The difference between the cross-docking of the 1930s and today, however, is that modern logistics technology can help companies ensure that nothing is lost or misplaced in the cross-docking shuffle, enabling it to become a normal part of the delivery process – and enabling a greater amount of goods to be managed and delivered through cross-docking.

What Exactly is Cross-Docking?

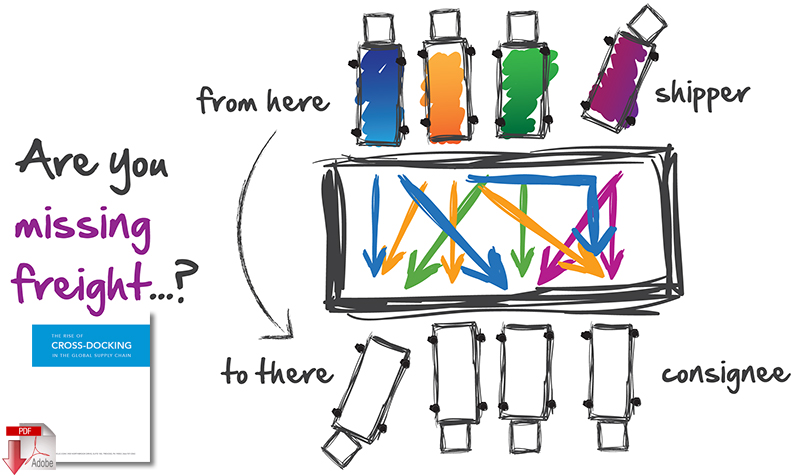

Cross-docking today has come to be defined as unloading materials directly from one vehicle and on to the next without first dropping off goods in a warehouse or facility. The idea is that, with the proper planning, the right goods can make it from point A to point B quicker if they’re moved directly to the next step of their delivery journey, rather than unloaded and stored.

We all live and work in a world where faster is better – but at the same time, it’s a world where it’s hyper-critical for orders to be correct and on-time. The speed and effectiveness with which companies can transport items to end users can have a significant impact on the bottom line and the retention of customers.

Companies understand how cross-docking can help cut costs and increase the speed of delivery, but as supply chains become more and more complex, the proper management of these increasingly complex cross-docking situations has remained an issue.

Many companies have simply found cross-docking too complex and difficult to get a handle on – or have had bad experiences trying to manually manage the process – using expensive, inaccurate and outdated paper-based systems, or even by adding supervisors and managers that would try and manage cross-docking on-site.

In these instances, companies have found that the added process drove up expenses and lowered speed – leading them to eventually step away from the potential benefits of cross-docking.

Accuracy and Speed Go Hand In Hand

It is critical that your supply chain is not sacrificing accuracy for speed.

Suppliers now are expected to deliver the perfect order in less time than ever before; in fact, with the trend of same-day shipping and increasing pressure to compete with companies like Amazon, many are trying to figure out how to profitably ship and deliver goods in 24 hours or less.

Companies no longer have the luxury of housing all their products in a central or regional warehouse and shipping from there. The efficiency of today’s supply chain depends on the ability of companies to move items directly from one truck to another – without losing momentum or breaking stride.

One example of where errors can happen is when a department store chain is trying to support in-store order fulfilment. To do so, it has to be able to locate various different types of goods – goods that could be spread out across different store and supplier locations.

After locating the goods, it must be able to ensure that items get on the right truck and get to the store in plenty of time to ensure the order is ready when customers arrive. Oftentimes these orders can be complex to manage and schedule to arrive at the location at the same time. Any misplaced items can be the difference between a repeat customer and lost business.

Another example is that, with the increasing complexity of types of goods being shipped from various locations – and customer expectations that those goods are available whenever and wherever they want them – many businesses have been forced to expand their logistics networks to compete.

This has resulted in an increase in the number of third-party logistics providers (3PLs) being utilized on a regular basis. Any disconnects between the originating company and the 3PL could mean an order ending up at the wrong dock, or even on the wrong truck, resulting in unhappy customers or lost business.

Human error is a fact of life. Unfortunately, it also can lead to gaps when one person notes an order was appropriately transferred at the cross-dock, but the order arrives incomplete or damaged at its end destination. Those mistakes can and do lead to millions of dollars in losses.

Eliminating Paper and Heightening Visibility

Effective cross-docking requires real-time visibility of goods as they are received, staged, loaded and distributed to their final destination. You can’t improve what you can’t control.

Without the ability to have real-time visibility on shipments – down to individual pieces or items –you can lose control over inbound shipments, increasing the potential for losses, delayed shipments and other errors that reduce the operational efficiencies gained by using a cross-docking model in the first place.

Hand-in-hand with improved visibility is the elimination of paper-based processes. With the ever-increasing number of stakeholders involved in a shipment and delivery – from companies to drivers to 3PLs – paper-based inventory and order tracking simply leave too much room for errors.

While every product originates from a specific company, in today’s world of complex, cross-network supply and demand, a product can pass through multiple vendors, delivery modes and personnel before arriving at the final destination. With hundreds, even thousands of orders moving through the cross-dock daily, it is all too easy for an item to be left behind, dropped, crushed, or simply mislabeled and loaded on to the wrong vehicle.

It is this complexity combined with outdated paper tracking processes that leaves plenty of room for improvement in logistics management.

Making Cross-Docking Work

Cross-docking is very advantageous and can make your supply chain more efficient and less costly – when done right. To make cross-docking really work for your organization, it is imperative that you eliminate paper and fully embrace technology.

Regardless of business size, location or product, every organization can benefit from an electronic proof of delivery system (ePOD) that helps connect all involved stakeholders, eliminates paper tracking (and paper waste) and streamlines the overall delivery process.

ePOD systems are traditionally defined as electronic-based order-tracking solutions that confirm the amount of goods delivered, where and when they were delivered and records signatures and other data from the point-of-delivery. As technology has advanced over the past decade plus, so too has ePOD.

ePOD technology now makes it possible for each shipment or order to be individually tracked throughout the supply chain, with each stop noted and logged, recipient sign-off and any issues or comments captured electronically, and then submitted back through a common system. This means that ePOD can help you manage exactly what product is where and when – which is critical to making cross-docking work.

During cross-docking, automation ensures that each item can be quickly scanned and moved to its next transport vehicle swiftly and accurately, logging any issues and noting special care instructions along the way. The possibility of human error is dramatically cut down, as ePOD technology ensures that each product is in the right place, every step of the way.

Today’s BYOD (bring-your-own-device) workplace makes it even easier for companies to implement ePOD. Many systems will work with any device, meaning all of the various stakeholders inside and outside of the company can easily use the same technology to manage the system. With some systems, all that’s needed is for an app to be downloaded – eliminating one of the traditional roadblocks to standardizing on a technology across organizations.

Organizations looking to take advantage of cross-docking need to embrace ePOD technology to provide visibility, control and assured delivery confidence – which will in turn enable them to finally see the efficiency and cost reduction improvements that cross-docking has promised since the 1930s.

About the Author

Mike Lee has 20 years of experience in the communications and enterprise software industries, both as a leader of early stage companies and as an executive in multi-billion dollar corporations.

He has held a number of senior management positions with AT&T, Inc., including President of Cellular One, now AT&T in Boston. He also played integral roles on executive teams that successfully completed more than $1.5 billion in acquisitions, as well as carrying out initial and secondary public offerings.

Mr. Lee was the CEO and founder of AirVersent, Inc. prior to its merger with Airclic. Prior to AirVersent, he held the position of Chief Operating Officer of SK USA, the U.S. headquarters of the $70 billion SK Group and owner of SK Telecom.